An experimental system and test method for tbm tunneling auxiliary rock breaking

An experimental system and rock-breaking technology, applied in the testing of mechanical parts, the testing of machine/structural parts, and the testing of material strength by applying a stable shear force, which can solve the problems of low safety, low work efficiency and low construction accuracy. and other problems, to achieve the effect of high safety and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the examples. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

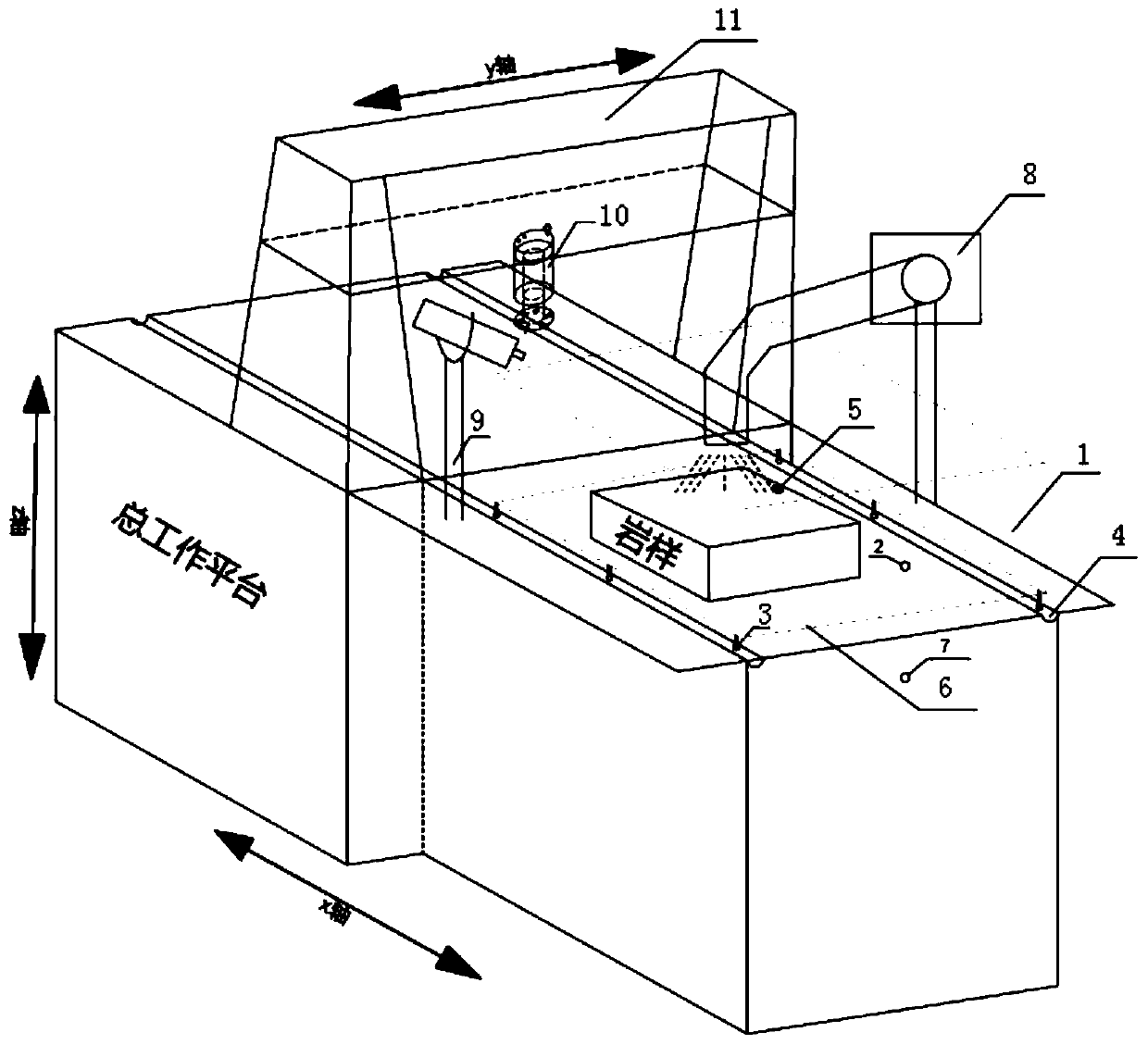

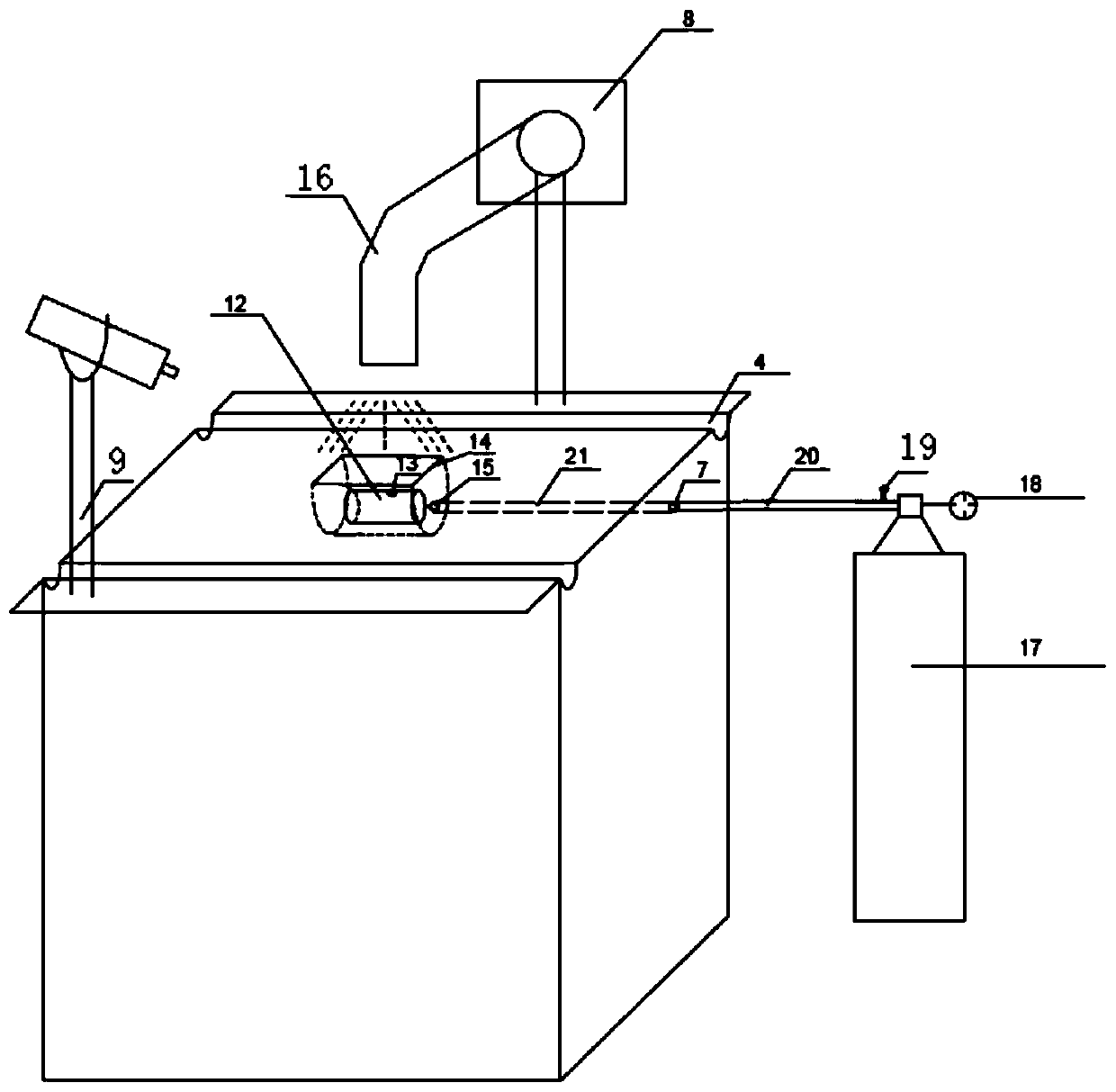

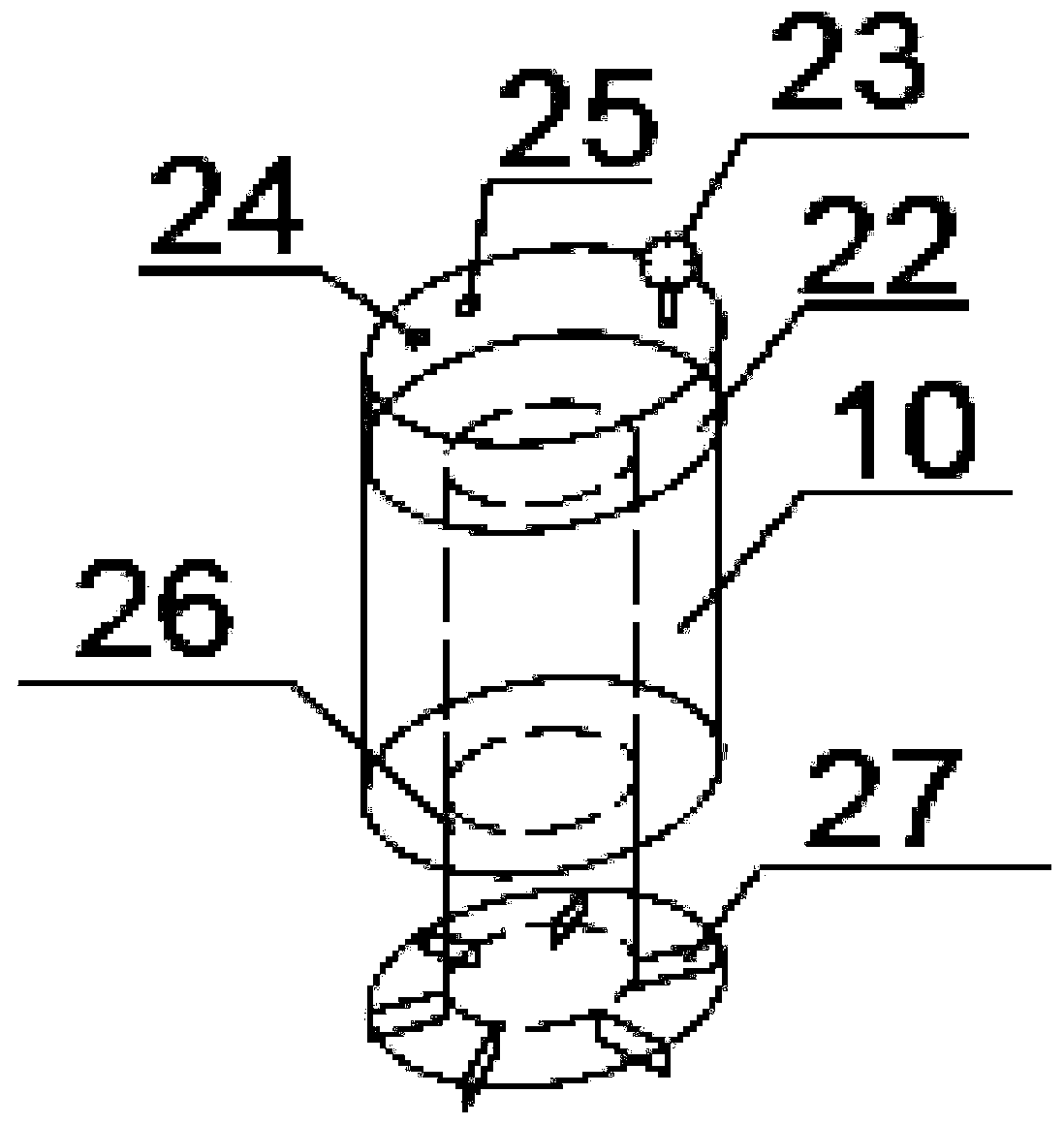

[0042] Such as figure 1 As shown, an experimental system for assisting rock breaking by TBM excavation includes a slidable support platform 1, a reserved hole 2 for the support platform, a lockable rolling wheel 3, a guide rail 4 for the support platform, a thermal loading platform 6, and a reserved hole 7 for the platform. Electromagnetic wave system 8, infrared thermometer 9, cutter head device 10, and cutter head reaction force frame 11.

[0043]The total working platform includes a platform support seat and a heat-loaded platform 6 arranged on the platform support, and the tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com