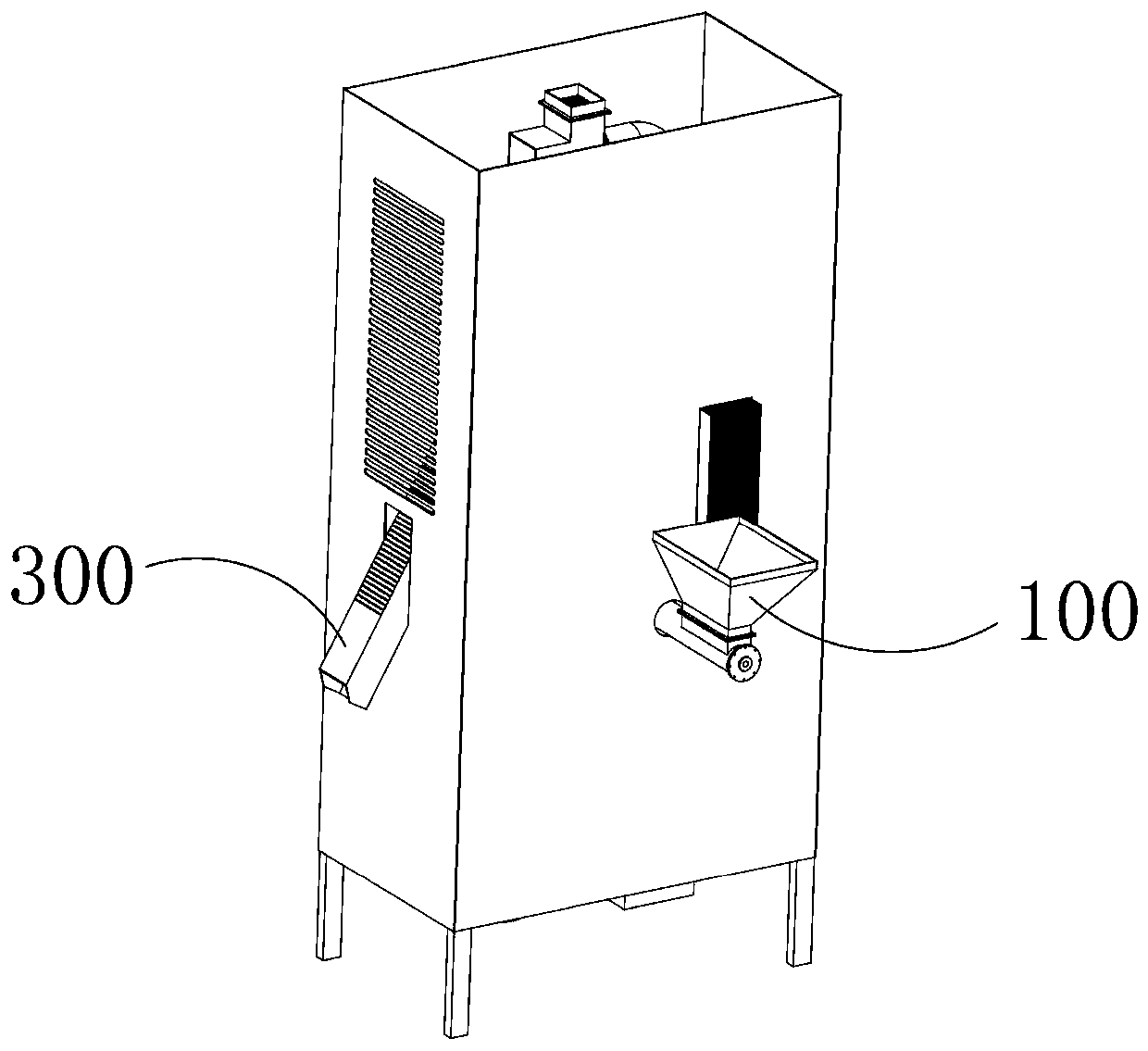

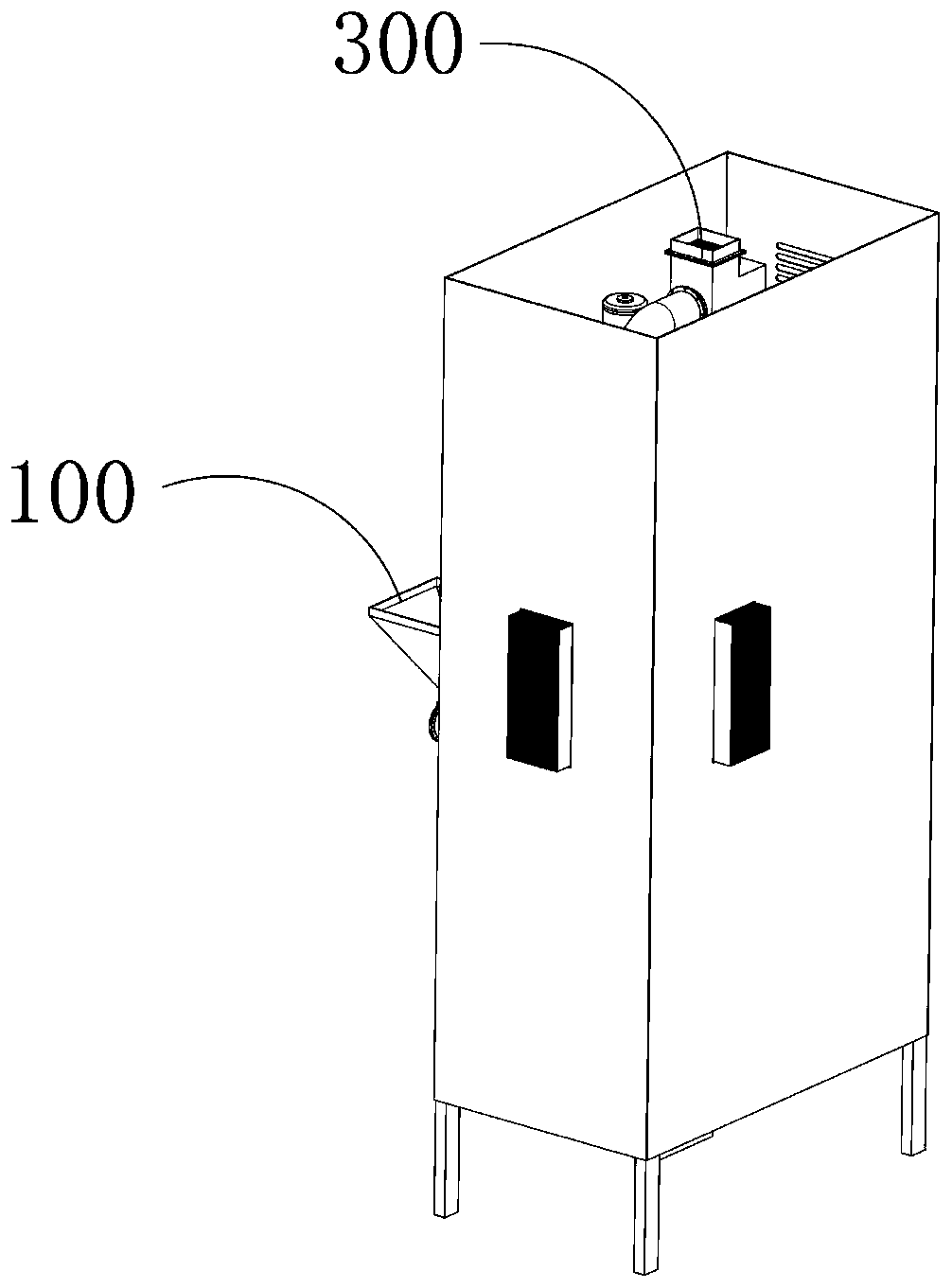

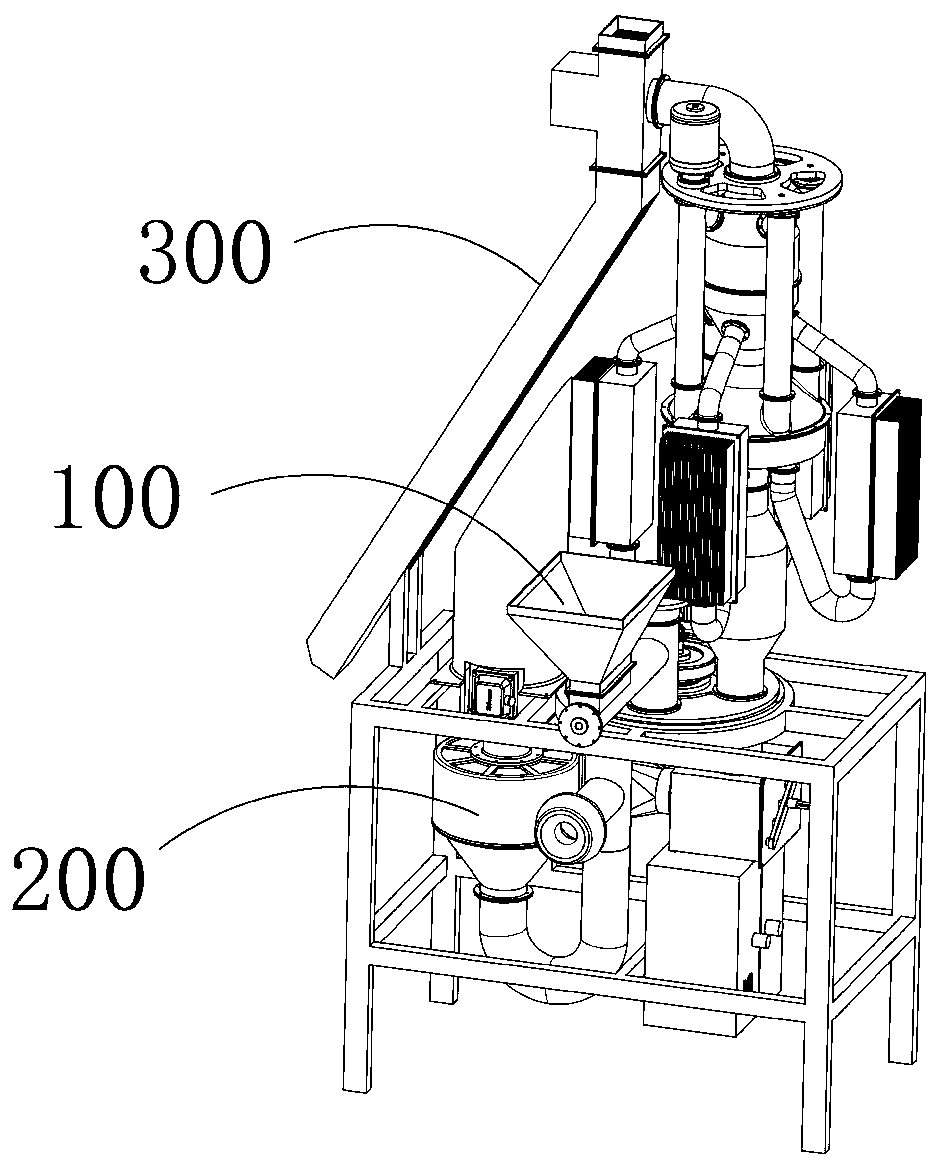

Floating type grain dryer

A drying machine, floating technology, applied in the field of grain processing, can solve the problems of easy induction of heat, fermentation, mildew, germination, easy damage, low efficiency of natural drying, etc., to achieve uniform and thorough drying and avoid cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The invention has the advantage of using hot air as the drying source and the method of suspending up and turning over to dry the grains. Before the grains are blown into the drying tank for drying treatment, the air blowing mechanism will pump the surface moisture of the grains. Suction treatment, so that the subsequent grain drying effect is better; when the grain is dried in the drying tank, it is blown upward by the wind, so that the grain rises in a tumbling manner, and the drying is more uniform and thorough; after drying During the discharge process, the grain is cooled by the cooling discharge device to avoid moisture when the dry and high-temperature grain is stored in a subsequent closed environment. At the same time, the cooling is divided into two stages. The hot air is used to cool down and use this as the cooling source, and the second-level cooling uses the wind blown by the cooling air pipe as the cooling source, and the grain is cooled by two gradual tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com