Bidirectional motion pneumatic flexible driver and working method thereof

A flexible drive and two-way motion technology, applied in the direction of manufacturing tools, program-controlled manipulators, manipulators, etc., can solve the problems of limited external space, increased gas pressure, large volume, etc., and achieve the effect of simple structural design and effective auxiliary force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described in detail below in conjunction with specific embodiments.

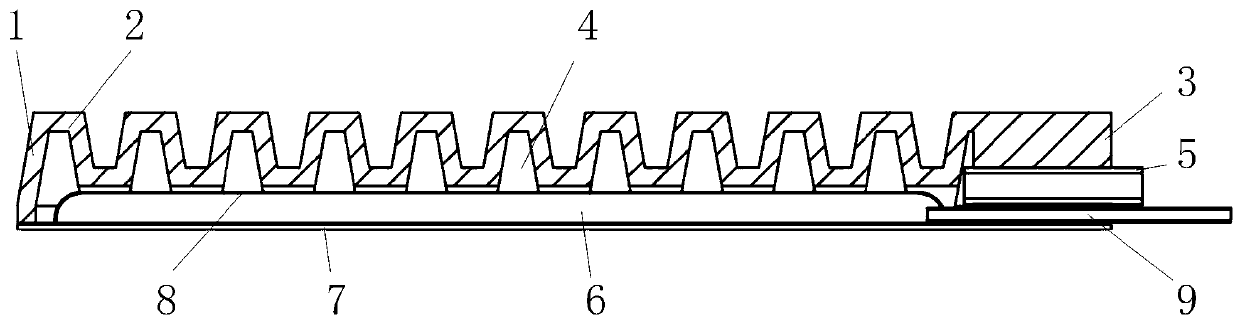

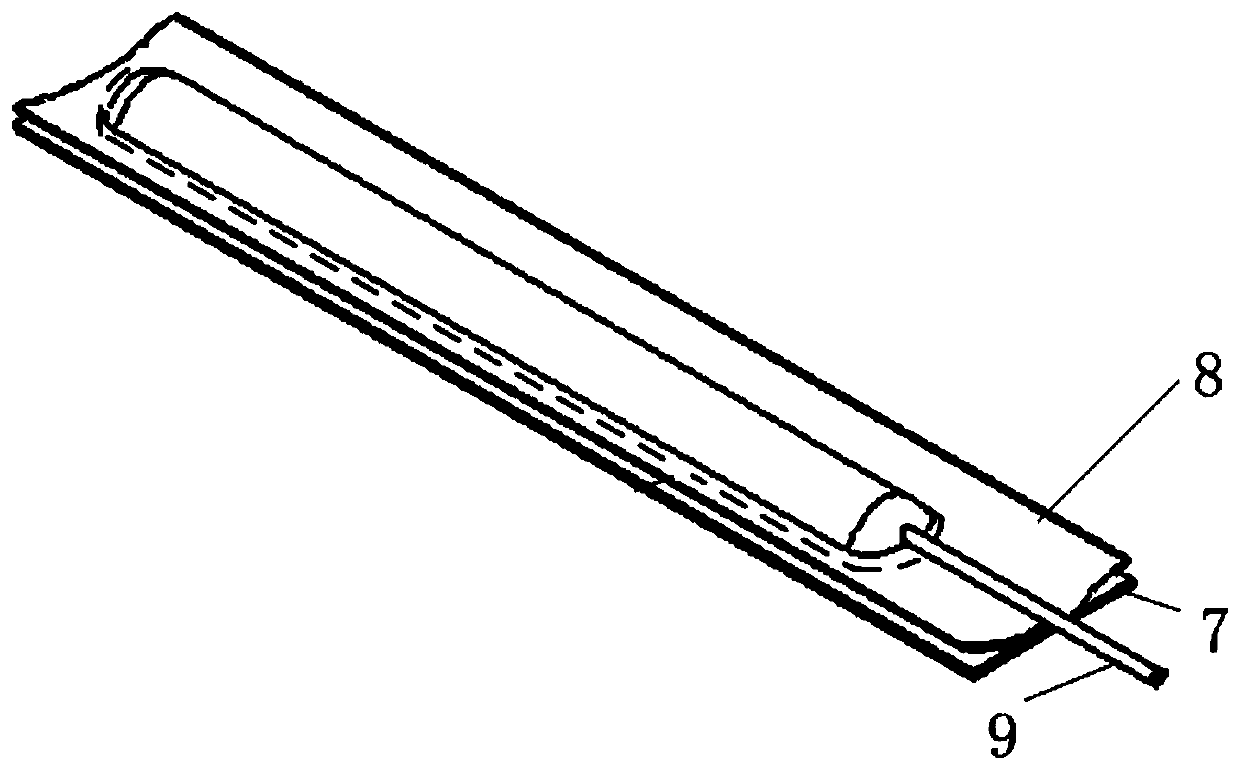

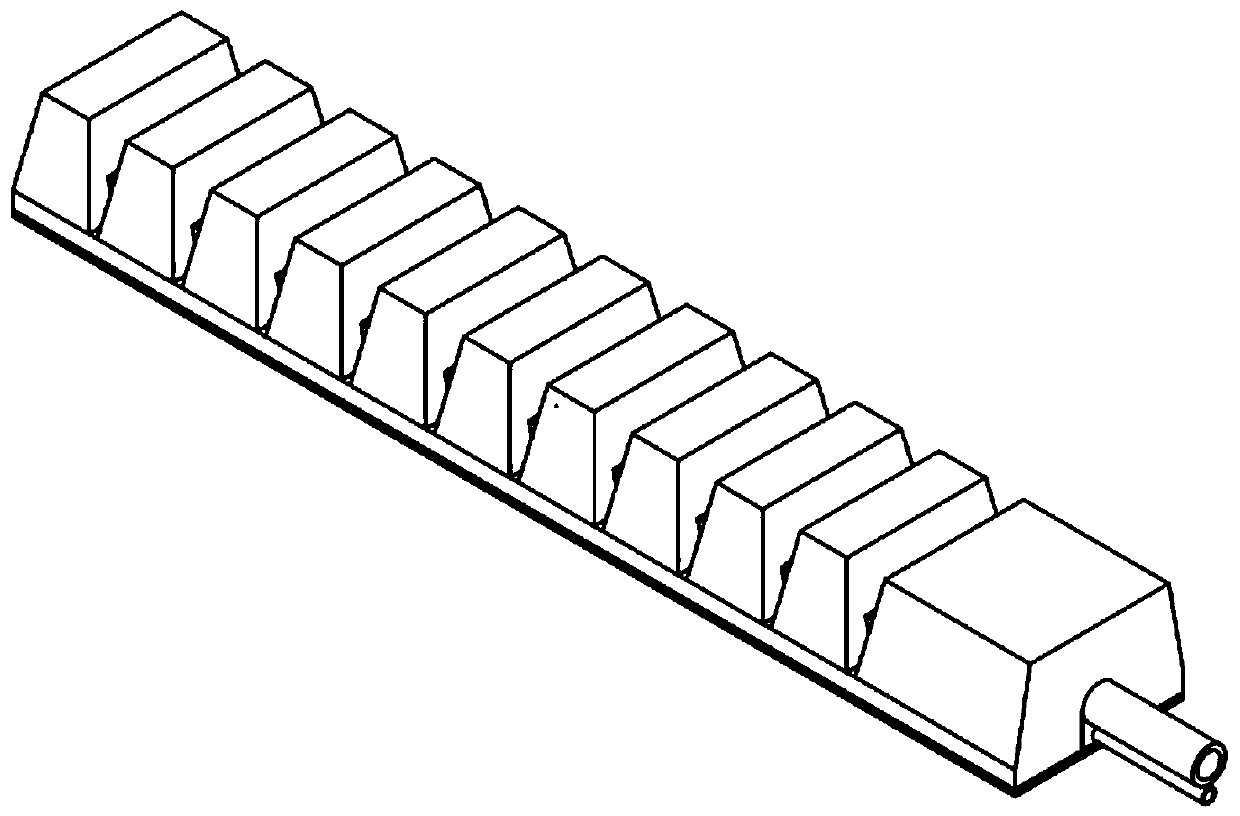

[0022] Such as Figure 1-3 As shown, a bidirectional motion pneumatic flexible driver includes a top air chamber 4 and a bottom air chamber 6, and the bottom air chamber 6 includes an upper plastic sheet 8, a lower plastic sheet 7 and a first flexible pipe 9, and the upper plastic sheet 8 and the lower plastic sheet 7 are connected by thermoplastic edge sealing so as to form an upwardly raised strip-shaped bottom cavity between the upper plastic sheet 8 and the lower plastic sheet 7, and one end of the first flexible pipe 9 communicates with the bottom cavity, The other end communicates with the air source or the atmosphere. The top air chamber 4 includes an elastic top air chamber wall and a second hose 5. The elastic top air chamber wall includes an integrally cast top air chamber front Wall 1, the middle wall 2 of the top-layer air chamber and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com