Method for machining arc and end surface of turbine guide blade of small gas turbine

A technology of turbine guide vane and processing method, which is applied in the field of grinding and processing, can solve the problems of processing deformation, technical blockade, high processing difficulty, etc., and achieves the effect of improving measuring tools and fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for processing a circular arc and an end surface of a guide vane of a small gas turbine turbine, comprising the following steps:

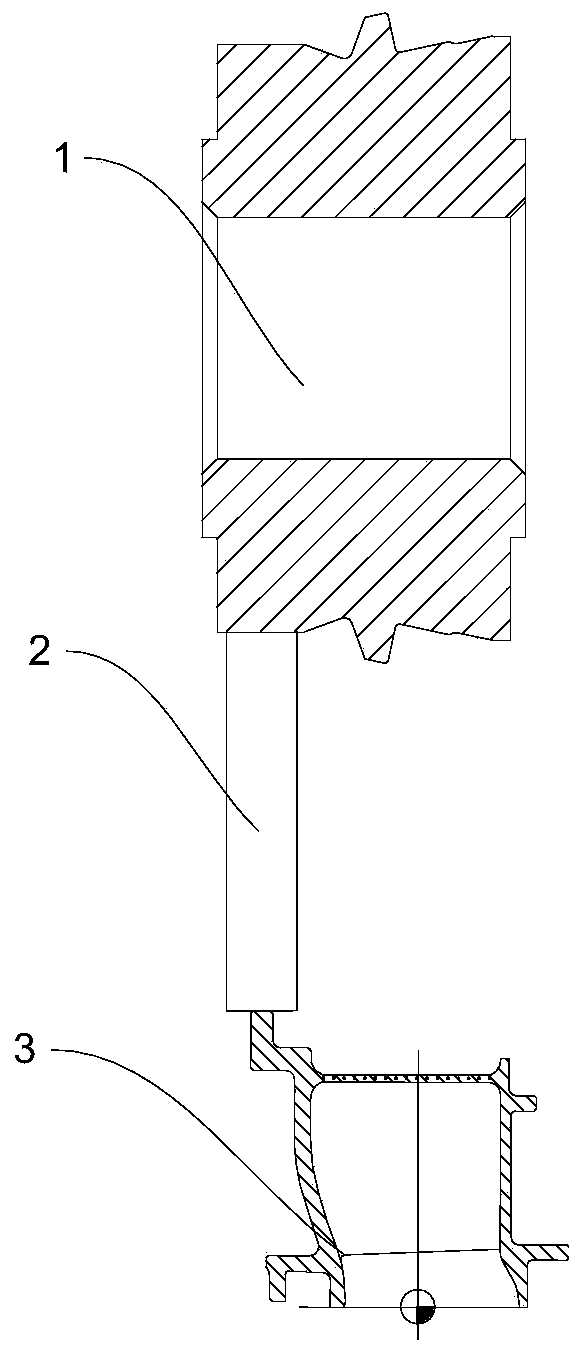

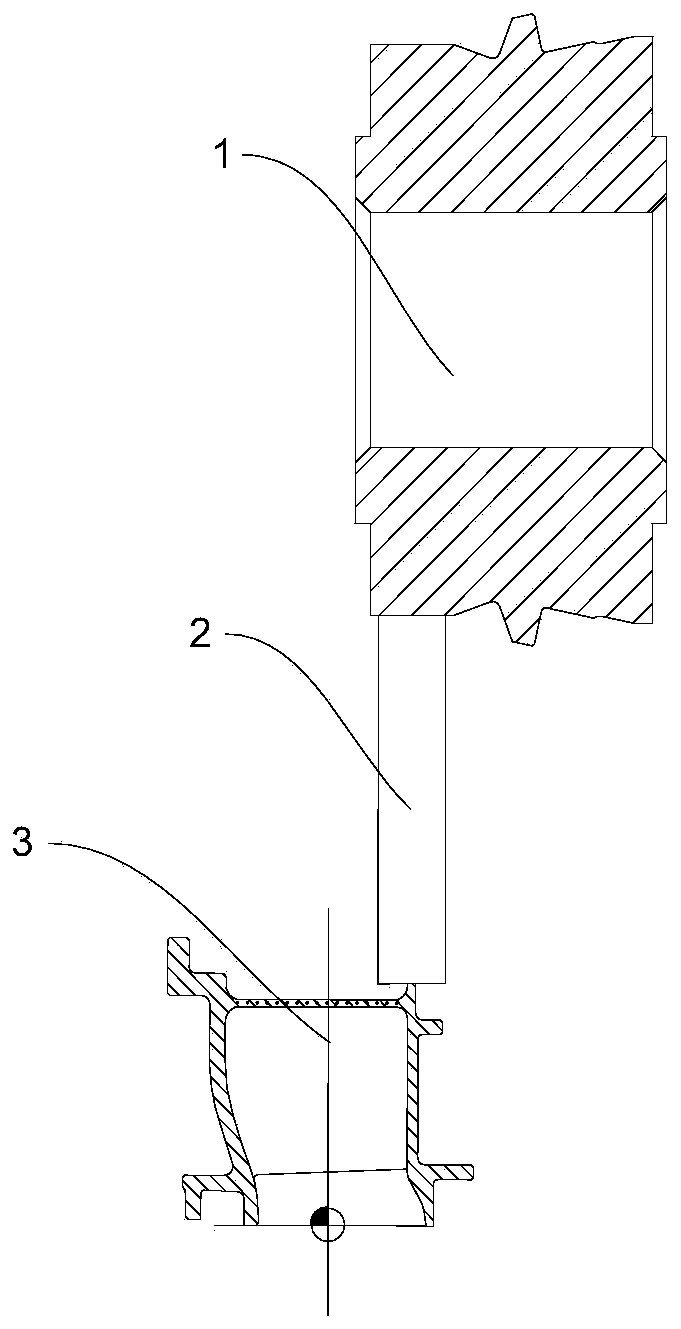

[0032] S01: Install the turbine guide vane, the grinding wheel 2 and the roller 1 attached to the surface for grinding the particles of the grinding wheel 2 on the five-axis machining center;

[0033] S02: Contact the grinding wheel 2 with the roller 1 to ensure that the grinding surface of the grinding wheel 2 is in full contact with the dressing surface of the roller 1;

[0034] S03: Make the grinding wheel 2 and the roller 1 move together and make the surface of the grinding wheel 2 contact the grinding surface of the turbine guide vane, and turn the grinding wheel 2 to grind the grinding surface of the workpiece. Since the grinding wheel 2 and the roller 1 are always in contact, the roller 1 is While the grinding wheel 2 is grinding, the roller 1 is trimmed;

[0035] S04: After finishing the grinding surface of a single turbine...

Embodiment 2

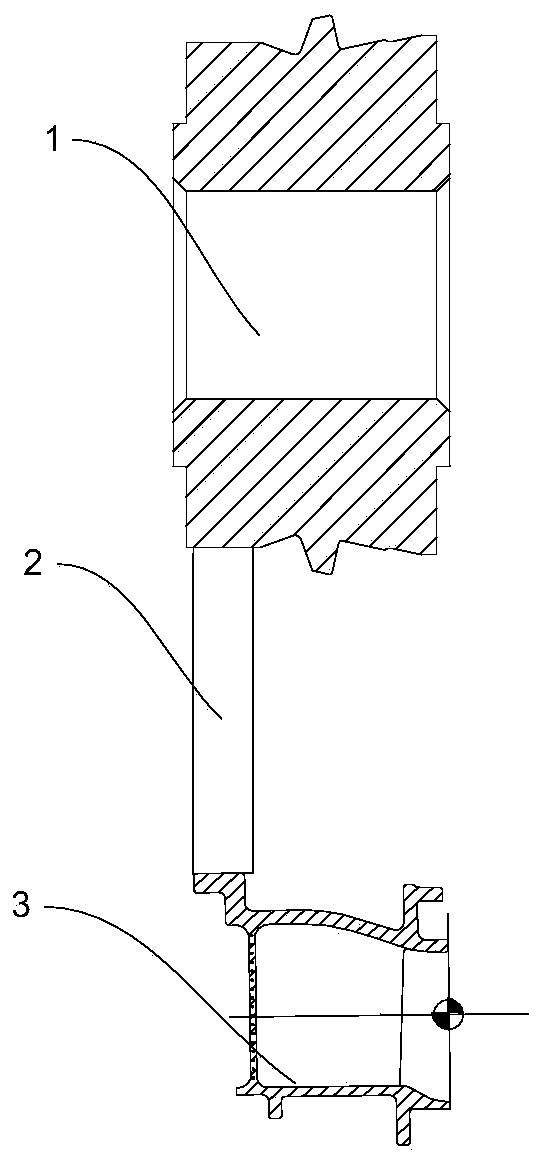

[0039] The difference between this embodiment and embodiment 1 is that in order to reduce the quantity of roller 1 and emery wheel 2, reduce the replacement frequency of processing tool, improve processing speed and further design to emery wheel 2 machine roller 1.

[0040] A method for processing a circular arc and an end surface of a guide vane of a small gas turbine turbine, comprising the following steps:

[0041] S01: Install the turbine guide vane, the grinding wheel 2 and the roller 1 attached to the surface for grinding the particles of the grinding wheel 2 on the five-axis machining center;

[0042] S02: Contact the grinding wheel 2 with the roller 1 to ensure that the grinding surface of the grinding wheel 2 is in full contact with the dressing surface of the roller 1;

[0043] S03: Make the grinding wheel 2 and the roller 1 move together to make the surface of the grinding wheel 2 contact the grinding surface of the turbine guide vane, and turn the grinding wheel 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com