Laser welding technology for negative pole ear and battery case of cylindrical lithium-ion battery

A lithium-ion battery, laser welding technology, applied in cylindrical shell batteries/batteries, laser welding equipment, secondary batteries, etc., can solve problems such as increased equipment maintenance costs, difficult to guarantee welding quality, and increased welding differences. , to achieve the effect of saving labor costs, stable welding, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

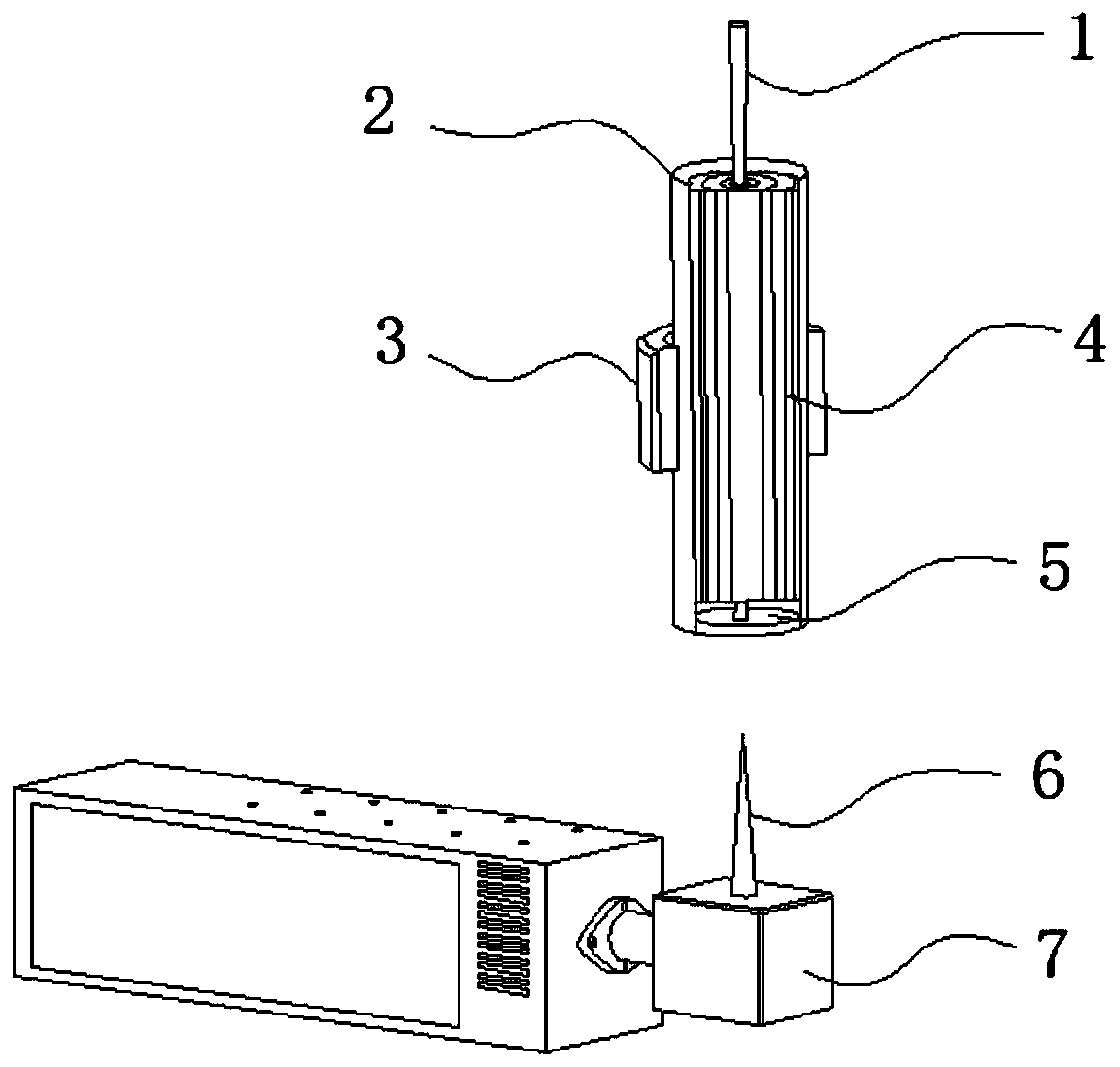

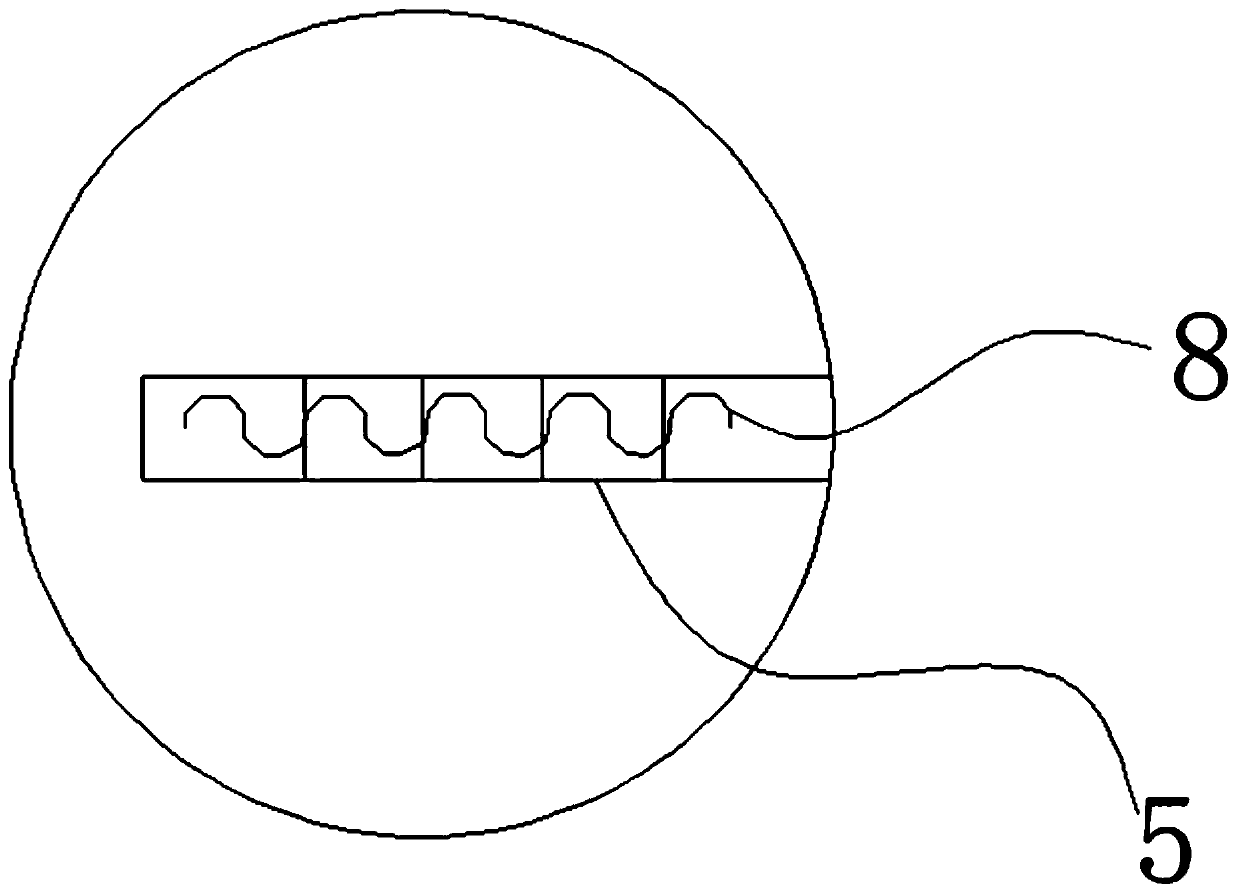

[0021] as attached figure 1 As shown, a cylindrical lithium-ion battery negative electrode ear and battery shell laser welding process, including a battery shell, the top side of the battery shell is installed with a pressing bar, and the battery bracket is installed on one side of the outer wall of the battery shell. A winding core is installed in the cavity of the battery case, a negative electrode tab is installed on the bottom side of the winding core, a laser welding machine is installed on the bottom side of the battery case, and a laser beam is emitted from the output end of the laser welding machine.

[0022] Specifically, the following steps are included:

[0023] S1: Fix the battery case on the battery bracket, and then the winding core is moved into the battery case;

[0024] S2: The pressing rod passes through the center hole of the winding core, and presses the negative ear and the battery case so that the two are in close contact;

[0025] S3: Turn on the laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com