Intelligent substation state monitoring system based on ubiquitous power internet of things

A technology of condition monitoring system and intelligent substation, which is applied in information technology support systems, electrical components, circuit devices, etc., can solve problems such as insufficient monitoring, inability to automatically locate high-temperature fault areas by visible light image fusion, and comparison, so as to improve data processing. Efficiency, data visualization, and the effect of saving communication resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

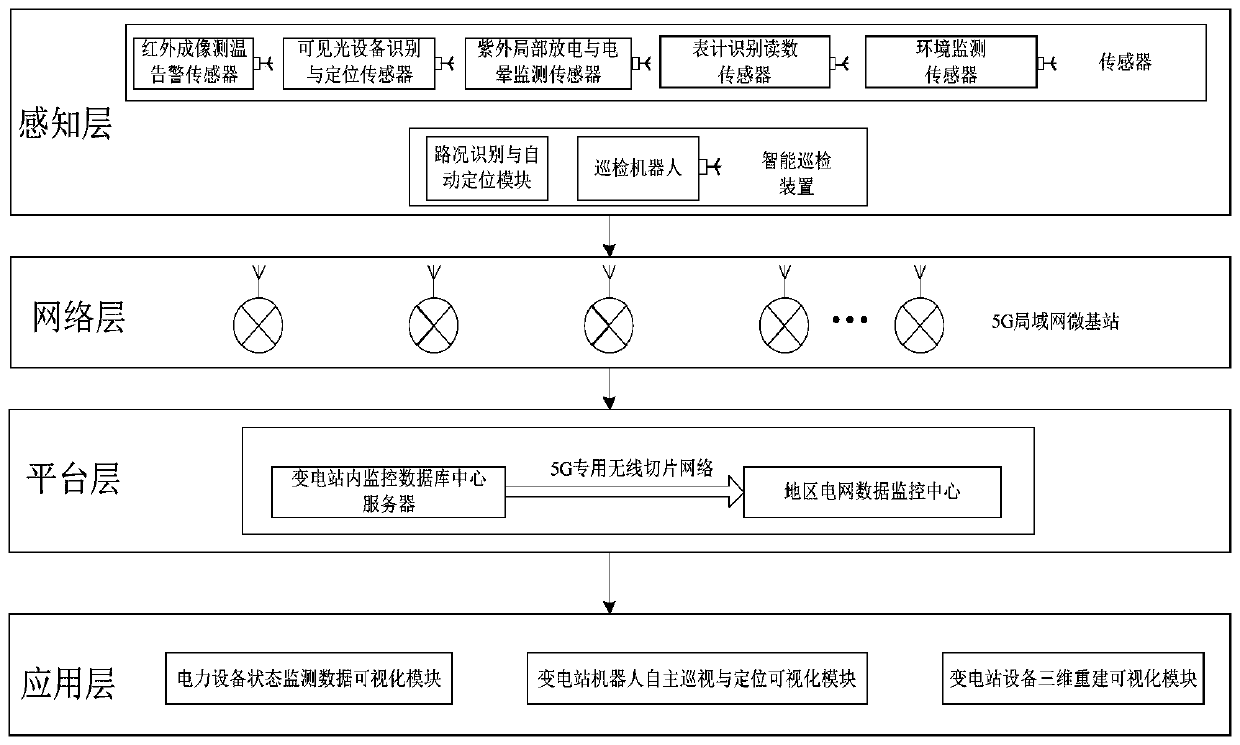

[0035] like figure 1 As shown, a smart substation status monitoring system based on ubiquitous electric power Internet of Things includes: perception layer, network layer, platform layer and application layer, see figure 1 The perception layer includes several sensors and intelligent inspection devices for collecting the state data of each power equipment in the substation; the data collected by the perception layer is transmitted to the network layer through wireless communication, and the network layer collects the data of each power equipment collected by the perception layer. State data integration, and transmit the integrated power equipment state data to the platform layer through wireless communication, and the platform layer transmits the received state data of each power equipment to the application layer through wireless communication. The application layer includes several visualization The module is used to complete the visualization of the status monitoring data o...

Embodiment 2

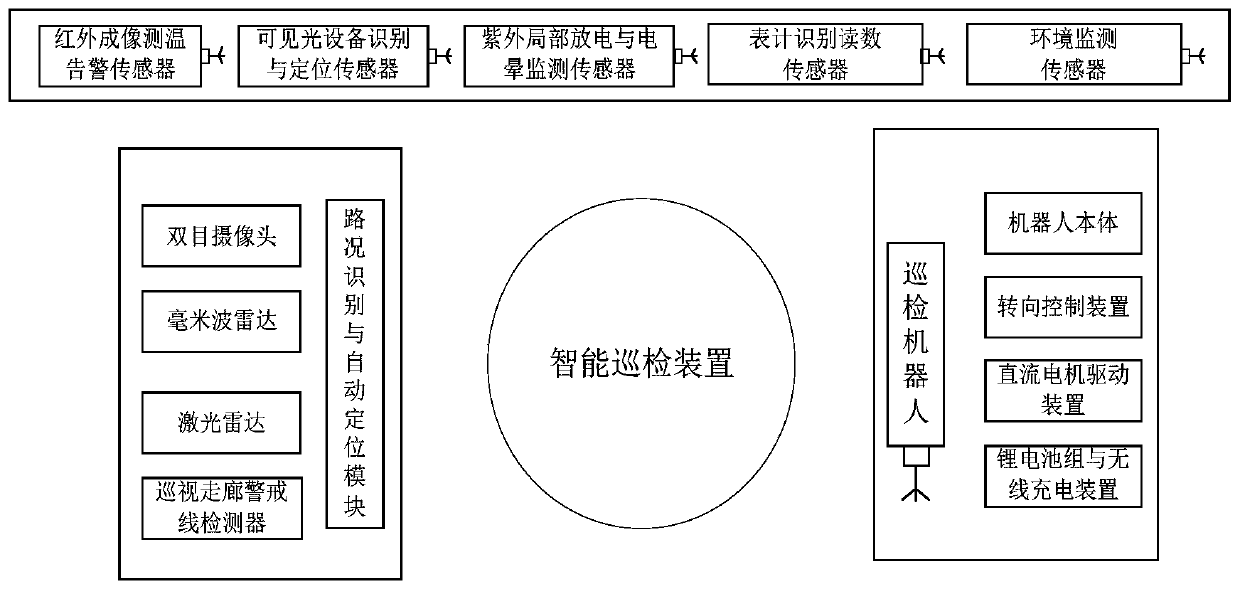

[0045] see figure 2 , The intelligent inspection device at the perception layer includes a road condition recognition and automatic positioning module, and an inspection robot; the inspection robot includes a robot body, a steering control device, a DC motor drive device, a lithium battery pack, and an unmanned charging device. The robot body is the sensor platform of the perception layer. The steering control device is controlled by the road condition recognition and automatic positioning module and background instructions. The DC motor drive device is the power device of the inspection robot, which is powered by a lithium battery pack that uses wireless charging. Compared with the socket charging method, the wireless charging method of the lithium battery has lower requirements on the fault tolerance rate of the charging positioning of the inspection robot.

[0046] The road condition recognition and automatic positioning module is equipped with a binocular camera, which is...

Embodiment 3

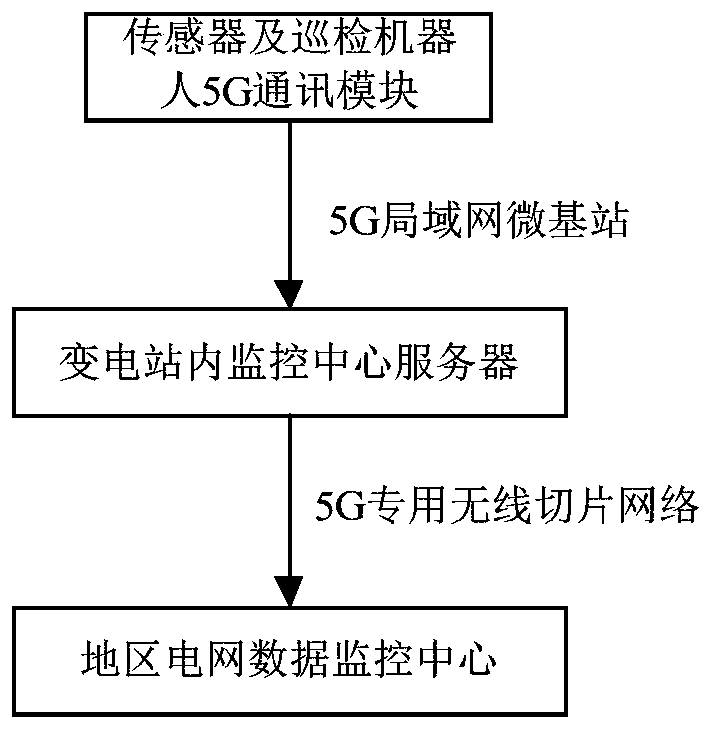

[0048] like figure 1 and image 3 As shown, the platform layer includes the database server of the monitoring center in the substation and the regional power grid data monitoring center. The 5G communication module integrates infrared imaging temperature measurement alarm sensors, visible light equipment identification and positioning sensors, ultraviolet partial discharge and corona monitoring Sensors, temperature monitoring sensors, humidity monitoring sensors, noise monitoring sensors and inspection robots monitor the state data of power equipment in the substation through the 5G local area network micro-base station at the network layer and transmit it to the database server of the monitoring center in the substation, which realizes the inspection robot shooting A large number of pictures and video data are transmitted in real time to the database server of the monitoring center in the substation for fast processing. The database server of the monitoring center in the subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com