Metal ion supplementing composite alloy powder as well as preparation method and application thereof

A composite alloy and metal ion technology, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., to achieve the effects of low cost, improved stability, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

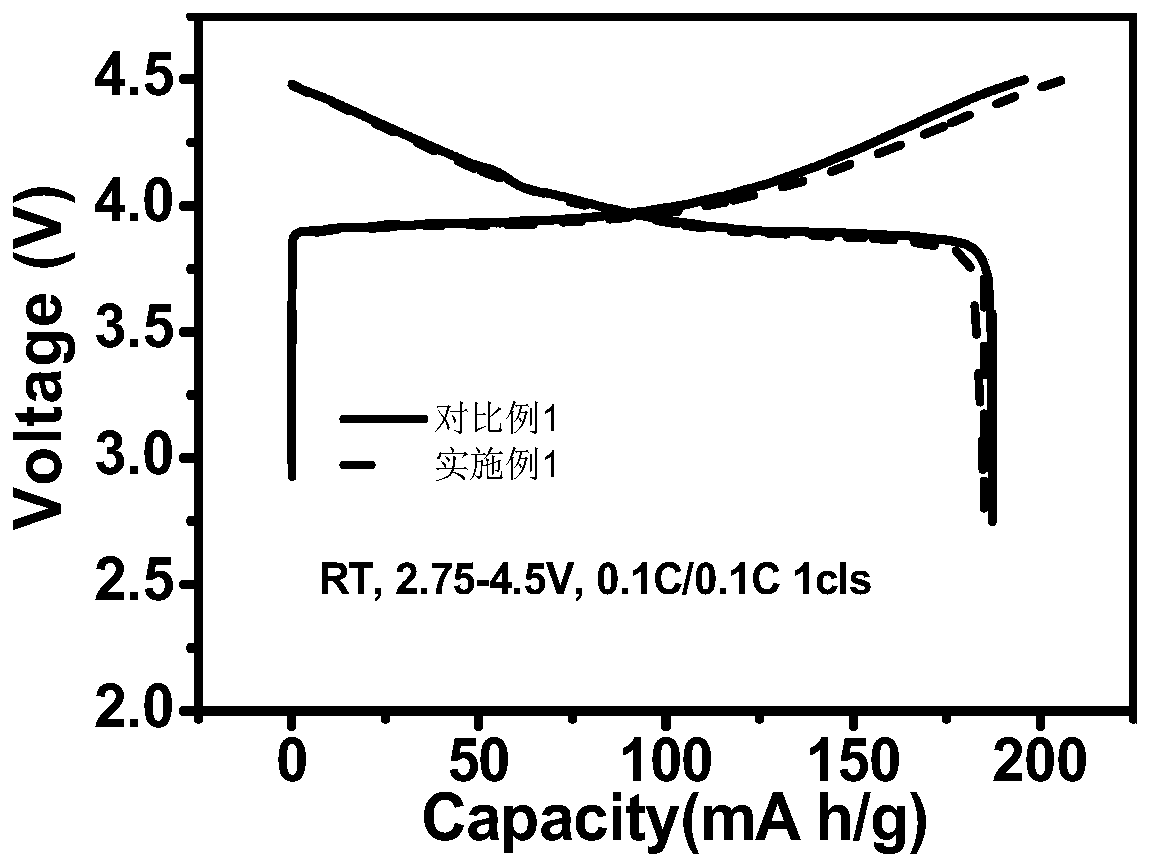

[0037] Such as figure 1 As shown, lithium cobaltate, A1 (see Table 1), acetylene black, and polyvinylidene fluoride are mixed according to the mass ratio of 91:5:2:2, N-methylpyrrolidone is added, and the mixture is stirred at high speed to obtain a uniform positive electrode slurry. And double-sided coating on 12 μm aluminum foil to obtain a positive electrode sheet, dried at 90°C for 4 hours to obtain a positive electrode sheet S1, rolled and punched for later use.

Embodiment 2

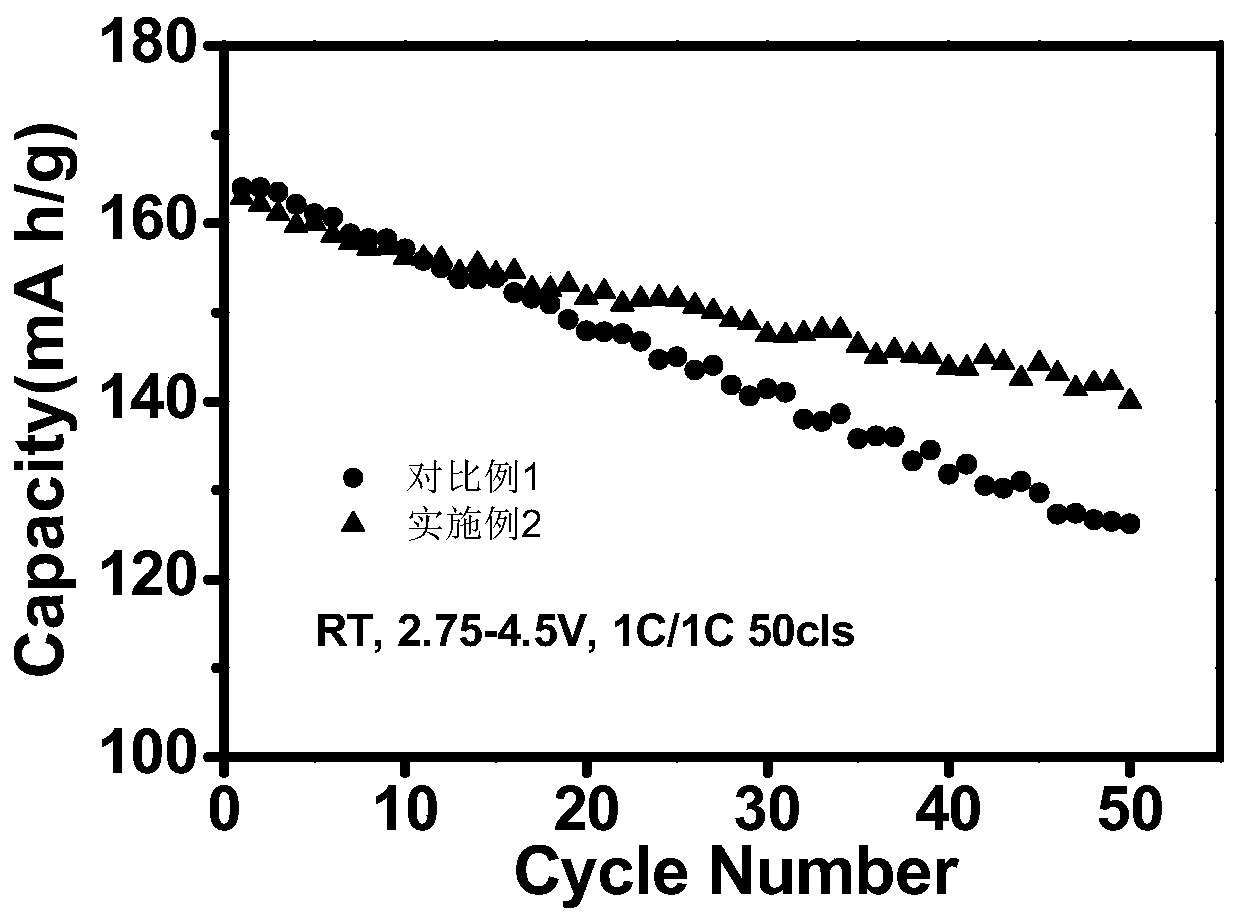

[0039]Mix lithium cobaltate, A2 (see Table 1), acetylene black, and polyvinylidene fluoride in a mass ratio of 90:6:2:2, add N-methylpyrrolidone, and stir the mixture at high speed to obtain a uniform positive electrode slurry The material was coated on 12 μm aluminum foil on both sides, and dried at 70°C for 6 hours to obtain the positive electrode sheet S2, which was rolled and punched for later use.

Embodiment 3

[0041] Mix NCM532, A3 (see Table 1), SP, and polyvinylidene fluoride according to a mass ratio of 92:4:2:2, add N-methylpyrrolidone, and stir the mixture at high speed to obtain a uniform positive electrode slurry, and Double-sided coating on a 12 μm aluminum foil to obtain a positive electrode sheet, dried at 70°C for 8 hours to obtain a positive electrode sheet S3, rolled and punched for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com