Elastic constant measuring method based on array magnet electromagnetic ultrasonic

An electromagnetic ultrasonic and elastic constant technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, instruments, analyzed materials, etc., can solve the problems of unmentioned elastic constant measurement method, low measurement spatial resolution, and complex measurement process, etc. Achieve the effect of meeting the needs of fast non-destructive and accurate measurement, improving spatial measurement resolution, and optimizing size and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

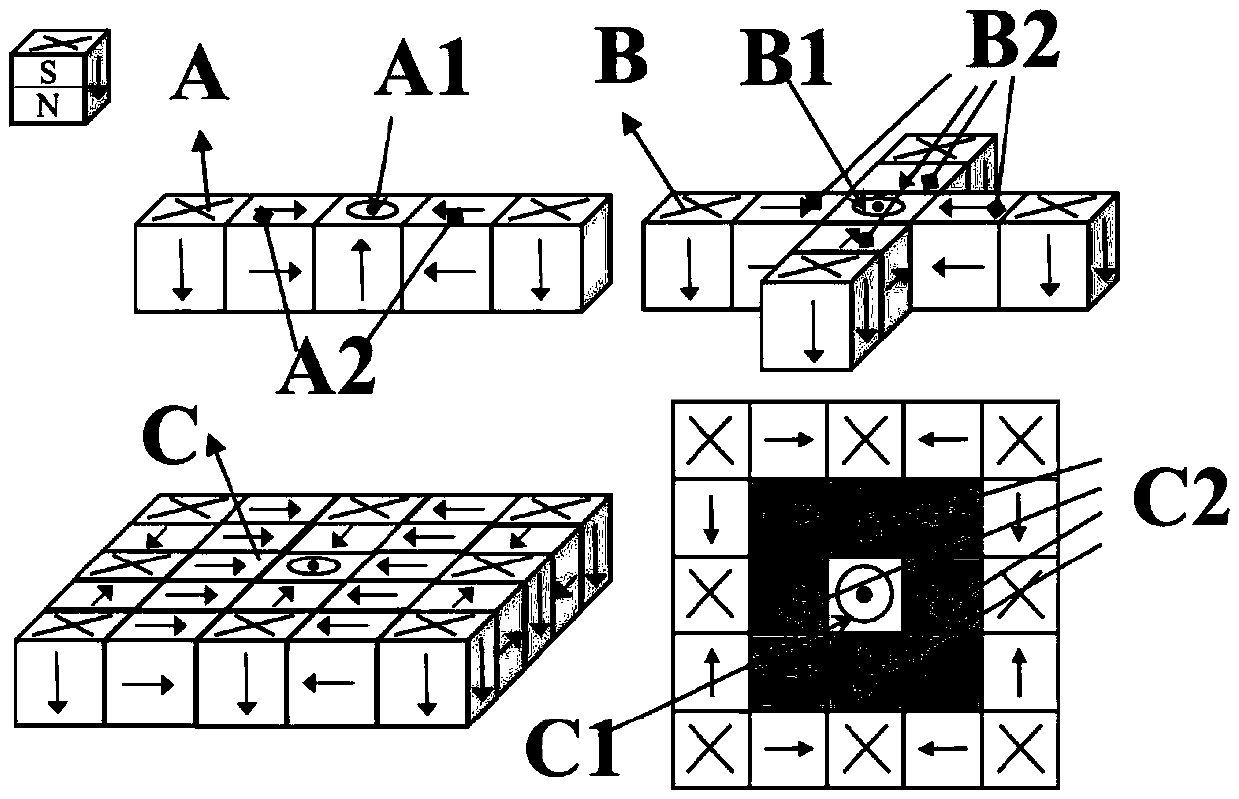

[0032] The specific implementation manner of the present invention will be described in detail in conjunction with the accompanying drawings and technical solutions.

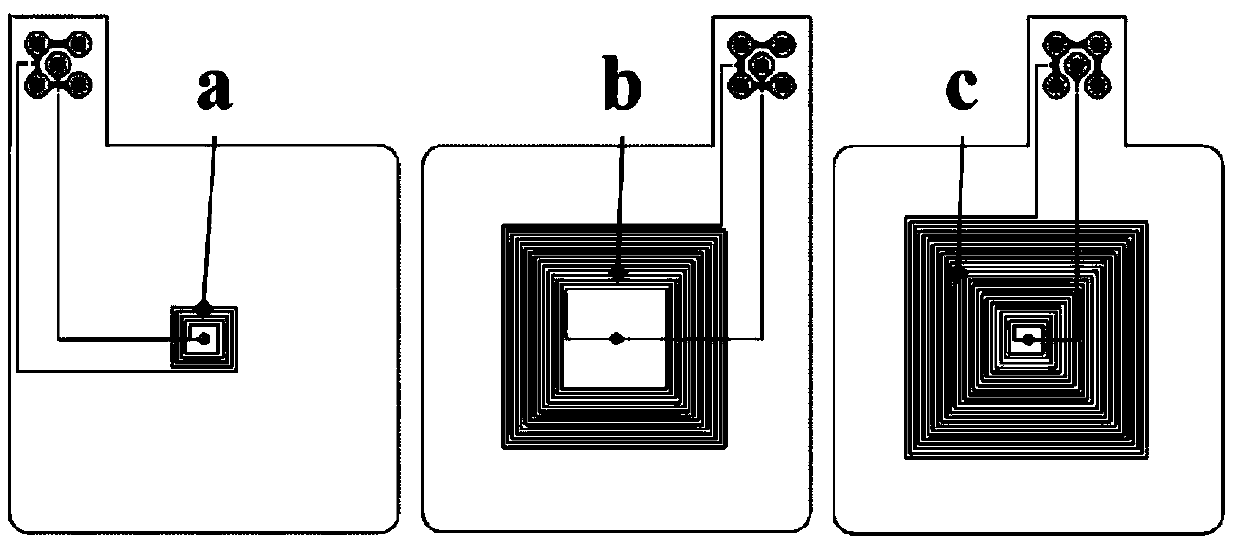

[0033] The main design parameters and assembly of the magnet array electromagnetic ultrasonic: the planar Halbeck magnet array C is made of 25 N52 NdFeB cubic permanent magnets bonded by resin glue. The size of a single permanent magnet is 4.7mm×4.7mm×4.7mm, and the overall size is 24mm×24mm×4.8mm; in the flexible printed coil structure, the size of the small square coil a is 4mm×4mm, the overall size of the square ring coil b is 14mm×14mm, and contains a square hole of 5mm×5mm in the middle, and the size of the ordinary square coil c is 14mm ×14mm, the thickness is 0.12mm.

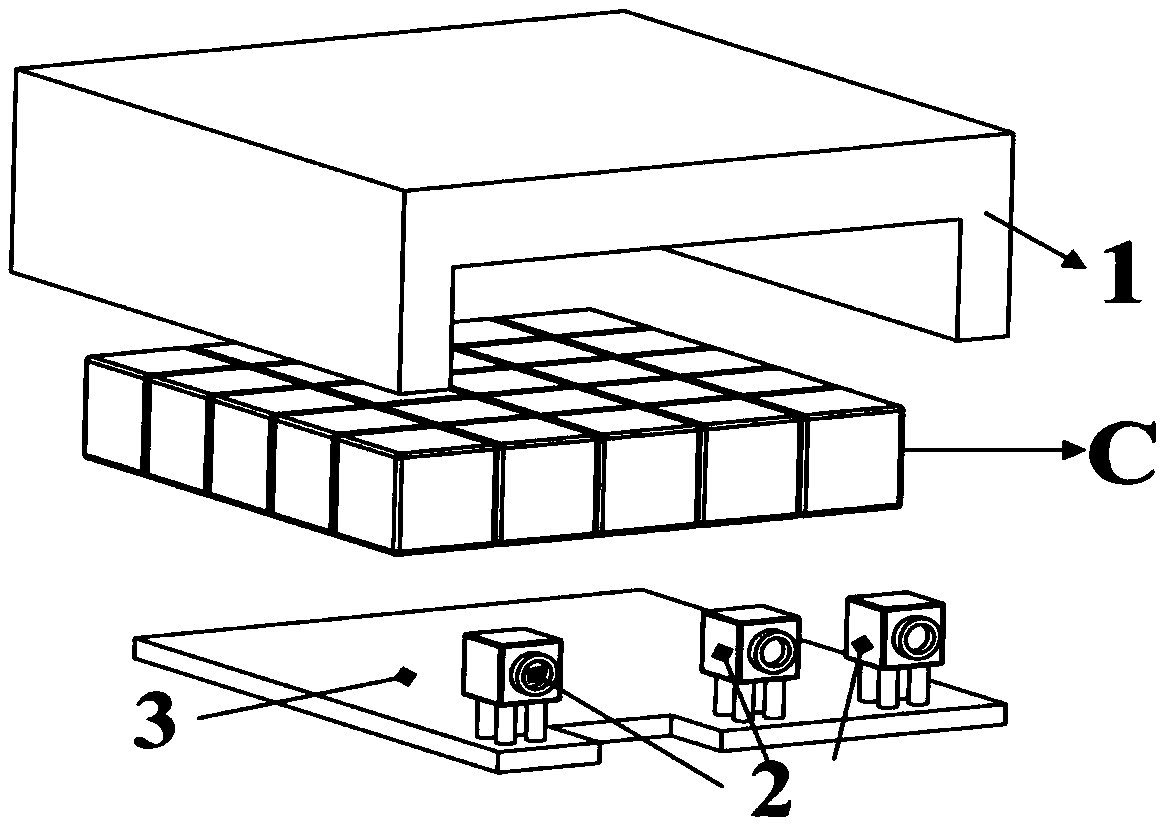

[0034] In the electromagnetic ultrasonic structure of the array magnet, the aluminum alloy casing 1 is optimally designed and manufactured, which not only has enough cavity to place the magnet array and printed coil, but also ensures a comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com