Rubber and plastic co-mixed waterproof roll construction method

A technology of waterproof coiled materials and construction methods, which is applied in the direction of building insulation materials, building materials processing, and roofs using flexible materials, etc., can solve the problems of long time consumption, complicated operation, and large physical strength, so as to save laying time, Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

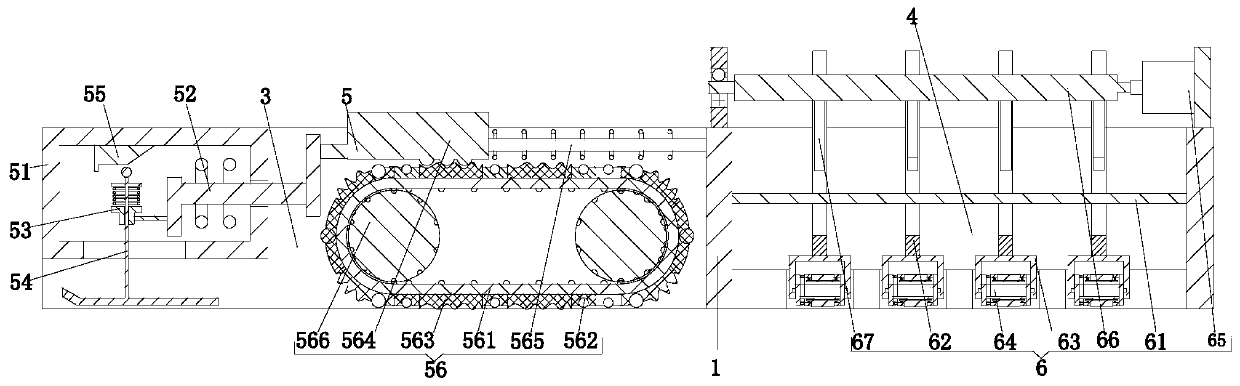

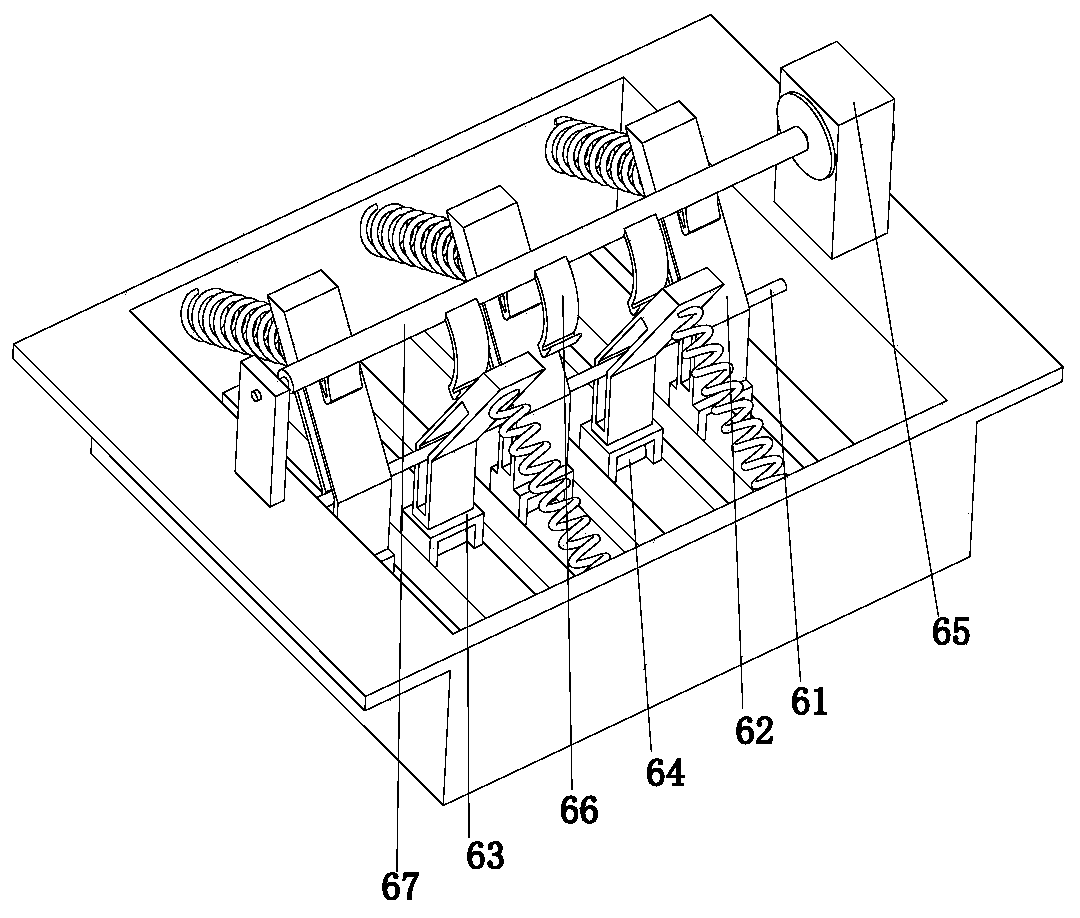

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

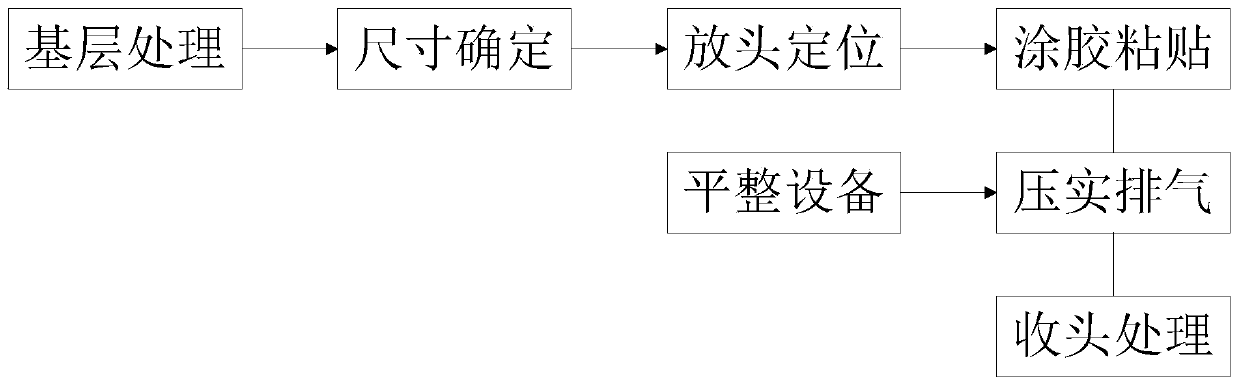

[0032] Such as Figure 1-5 As shown, a rubber-plastic blended waterproofing membrane construction method mainly includes the following construction steps:

[0033] Step 1, base treatment, manually use tools to clean the surface of the base to keep the surface of the base smooth, manually use a roller brush to evenly coat the modified asphalt adhesive thinner on the surface of the base;

[0034] Step 2: Determine the size, control the size of the waterproof membrane according to the specified construction requirements, use a tape measure to measure the width of the waterproof membrane waste that needs to be removed, and use a marker to mark the measured width, and use a cutting machine to cut the waterproof membrane , the waste after cutting is coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com