A mildew-proof and moisture-proof optical film and its preparation method

An optical film, anti-mildew technology, applied in optics, optical components, instruments, etc., can solve problems such as no more effective solutions, and achieve the effects of avoiding shadow effects, improving compactness, and inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

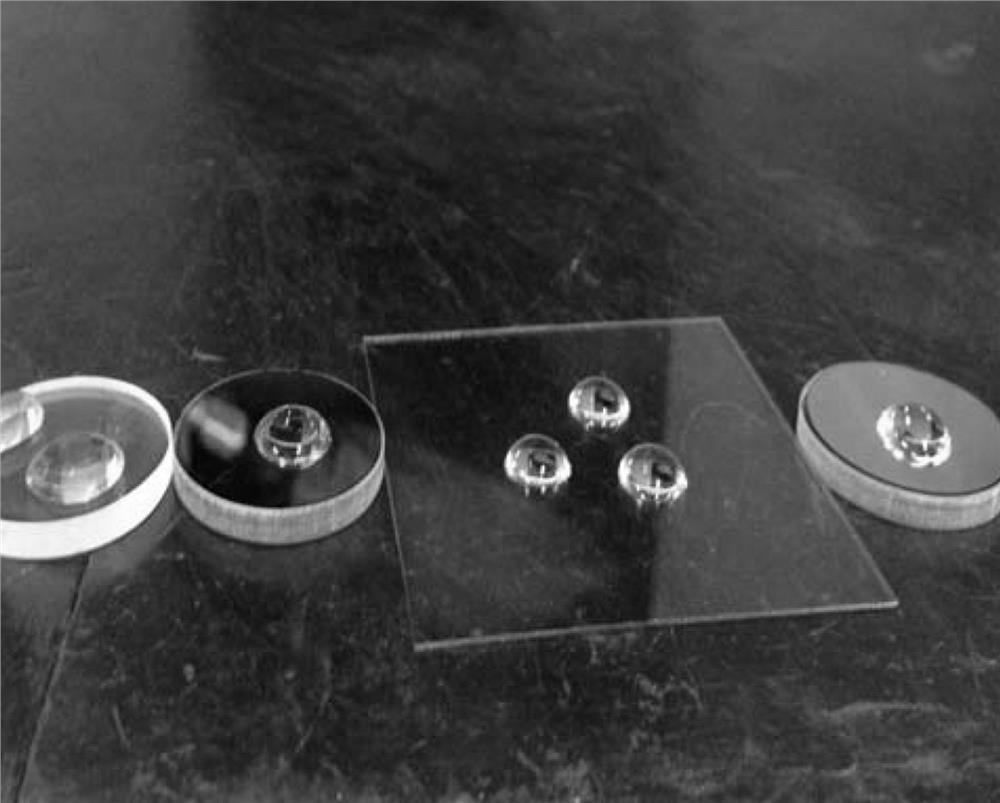

[0037] The moisture-proof and mildew-proof optical film involved in the present invention is realized on a Leybold SYRUSpro1110 vacuum coating machine; the equipment is equipped with an APSII plasma source, an electron beam evaporation system, and an IC5 film thickness monitor.

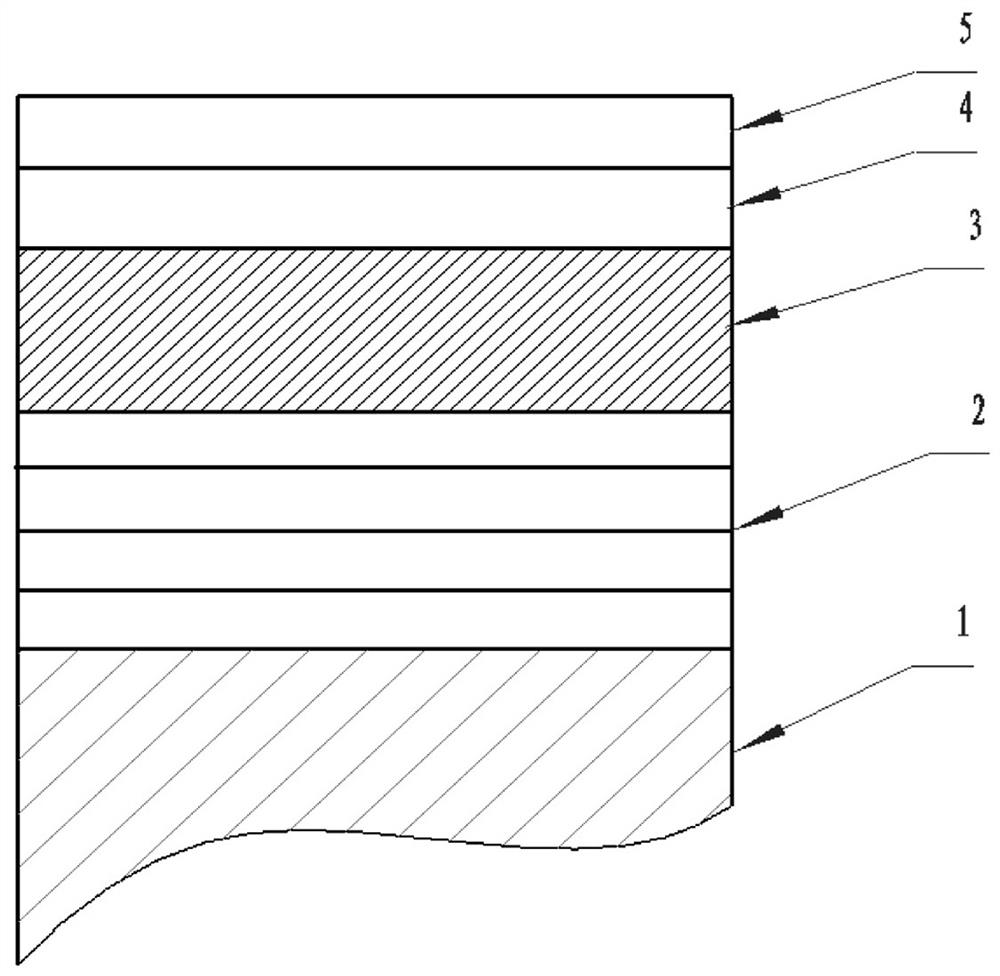

[0038] refer to Figure 1 to Figure 3 As shown, the present invention discloses a moisture-proof and mildew-proof optical film with high transmittance, including a substrate 1, a high-density anti-reflection film system main body 2 and a hard wear-resistant protective layer 3 evaporated on the substrate 1 in sequence , the first hydrophobic film layer 4 and the second hydrophobic film layer 5; the substrate 1 is glass, sapphire, zinc sulfide or silicon wafer of the same material as the optical window, so the substrate 1 of the present invention can be Lay on the optical window and form an integral body with it, and the optical window can also be used as the substrate 1 to evaporate other film layers seq...

Embodiment 2

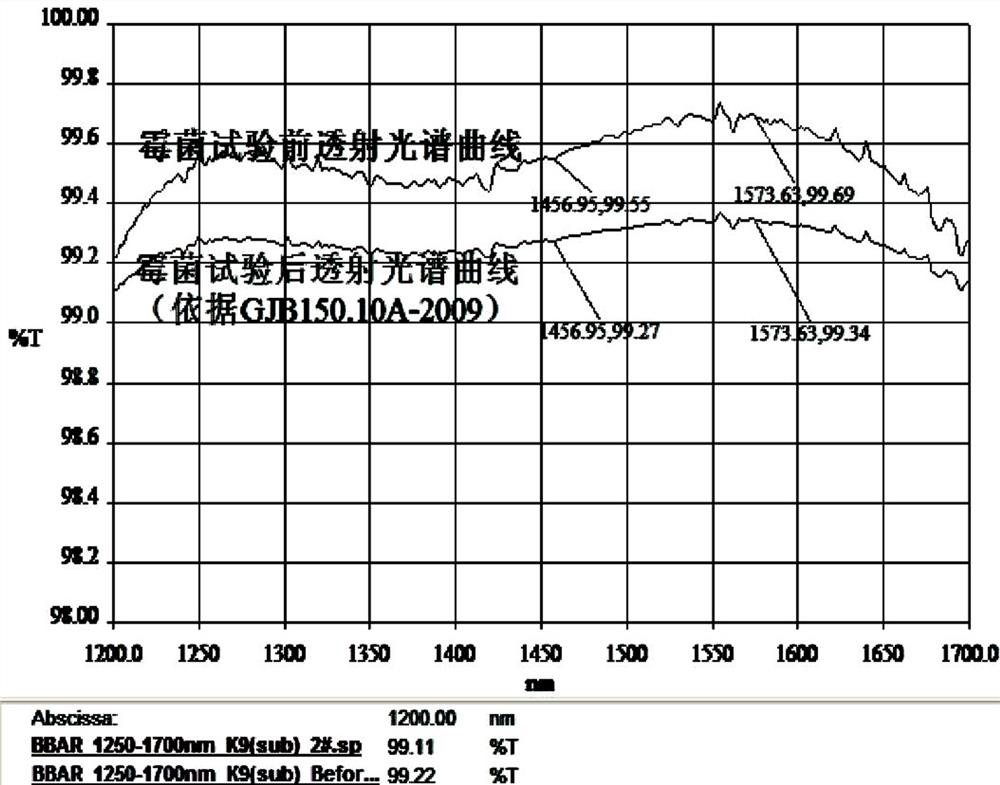

[0044] A high-efficiency anti-reflection film with moisture-proof and mildew-proof functions coated on a K9 glass light window, the size . The technical requirements are as follows: , incident angle 0-30 0 . The coating sample passed the high and low temperature, constant humidity, adhesion and severe friction tests specified in GJB2485-1995 at one time. At the same time, it can also withstand the mold test specified in GJB150.10A-2009.

[0045] First of all, according to the above technical requirements, the optimal design of the film structure is carried out, and the results are as follows:

[0046]

[0047] Among them, the material of the hard wear-resistant protective layer 3 is selected as SiO 2 , a-f are the physical thickness of the film layer, respectively, M1 and M2 are both fluorine-silicon-based organic hydrophobic film layers, and their physical thickness is 6.0nm. The physical thickness of other film layers is as follows:

[0048] a-70.25nm; b-82.66nm;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com