Method for simultaneously reducing cyanide and ethyl carbamate in cherry wine

A technology of urethane and cyanide, which is applied in the field of food processing, can solve the problems of light flavor after storage, short storage period, and shedding of fruit stems, etc., and achieve the goal of clear and transparent wine liquid, lower cyanide content, and lower content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

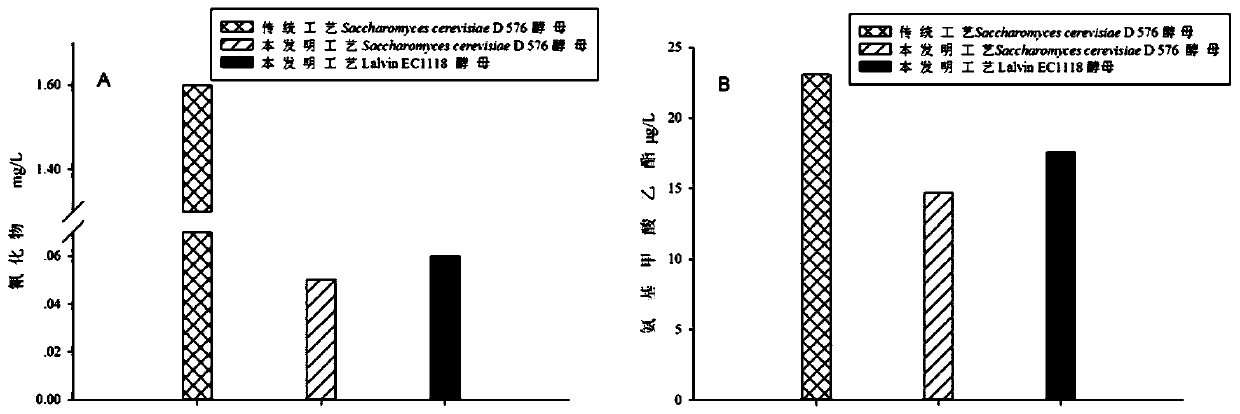

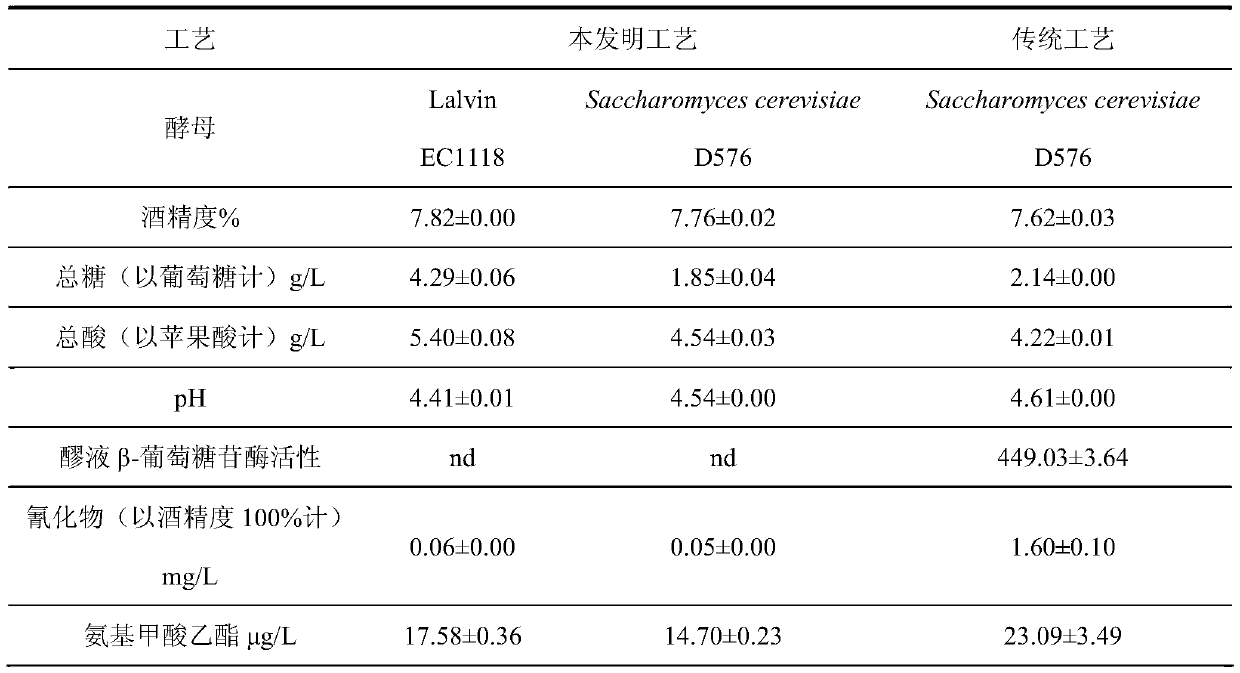

[0017] Embodiment 1, brew cherry wine by the inventive method

[0018] 1) Choose healthy cherries to wash with running water, remove sundries, and drain the water for later use.

[0019] 2) Crush the cherries to obtain cherry mash, and boil the crushed cherry mash at 100° C. for 5 minutes.

[0020] 3) Cool the boiled cherry mash to room temperature, inoculate Saccharomycescerevisiae D576 (SIHA Aktivhefe 7 fruit wine yeast, purchased from Weifang Kaiser Chemical Co., Ltd.) at 0.2g / kg cherry mash, and carry out alcohol fermentation at 20-25°C for 12 The liquor is separated after days; during the fermentation process, the cherry skin pomace floating on the surface is pressed into the fermentation broth every day.

[0021] 4) Carry out aging, clarification, filtration according to the conventional cherry fermented fruit wine process, and fill to obtain finished cherry wine (the indexes of the finished wine obtained are shown in Table 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com