Polypropylene flame-retardant material capable of being used for producing concealed bottom box and preparation method thereof

A flame retardant material, polypropylene technology, applied in the field of polypropylene flame retardant materials and its preparation, can solve the problems of low-temperature cold brittleness, low Vicat softening point, narrow processing temperature range, etc. Simple and reliable process, stable product color and wide processing temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

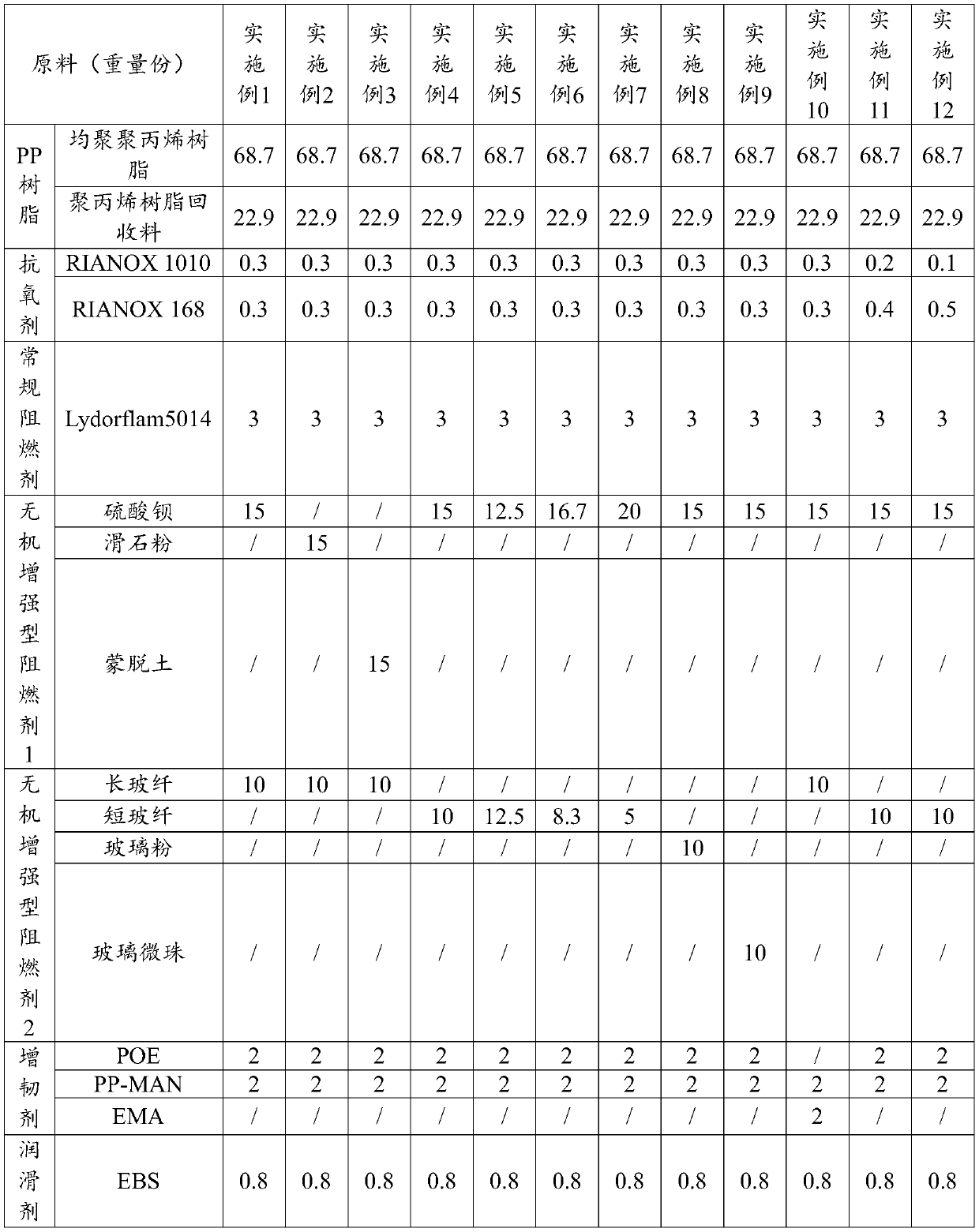

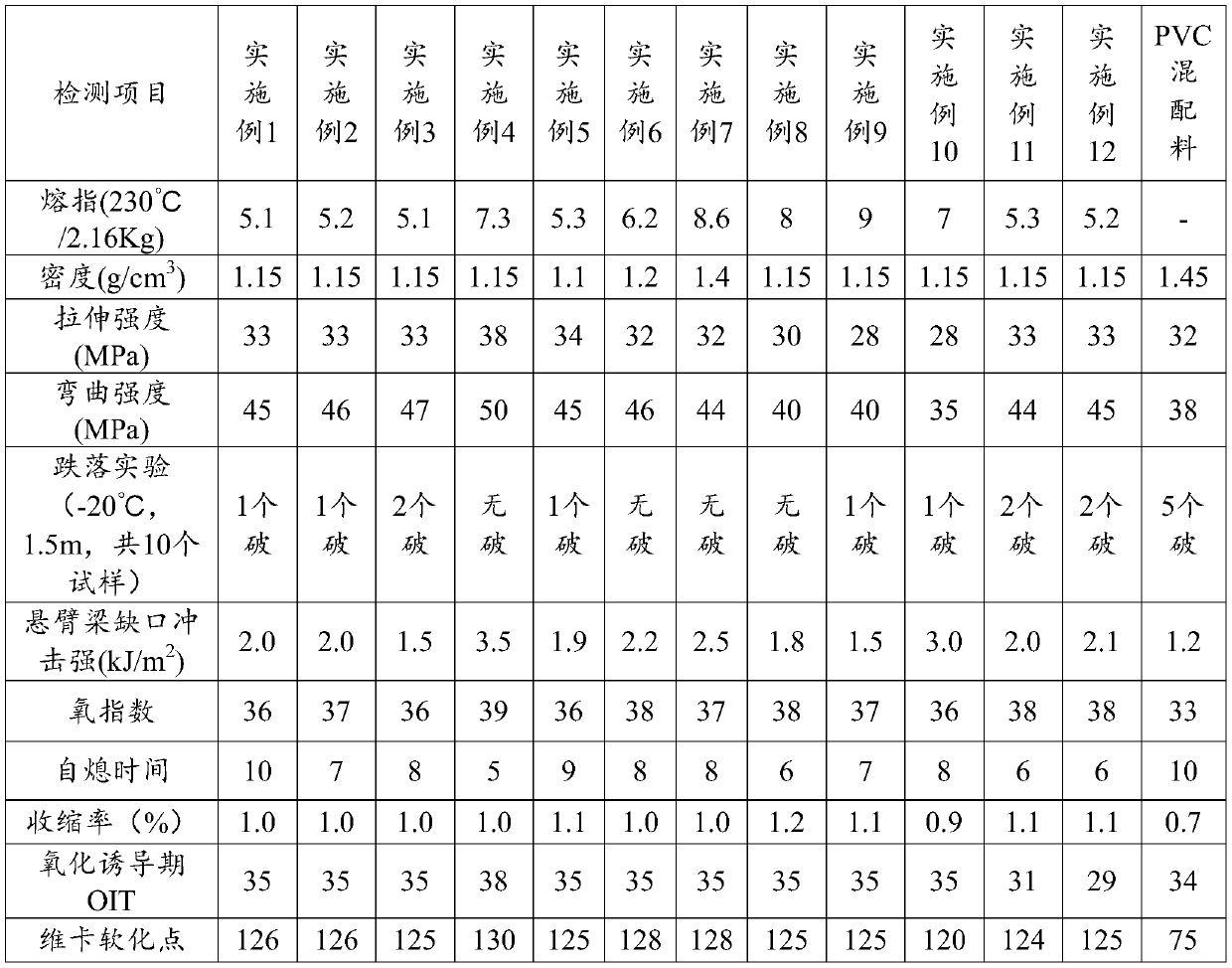

Embodiment 1-12

[0043] The composition of the polypropylene flame-retardant material that can be used for the production of concealed bottom box of embodiment 1-12 is as shown in table 1, wherein, the composition of the polypropylene flame-retardant material that can be used for the production of concealed bottom box of embodiment 1-12 The preparation method comprises the following steps:

[0044] (1) Take each component raw material in proportion, and put each component raw material into a high-speed mixer and mix for 5 minutes;

[0045] (2) Put the mixed material in a twin-screw extruder, and the processing conditions are: the temperature of the first zone is 170-180°C, the temperature of the second zone is 175-185°C, the temperature of the third zone is 180-190°C, and the temperature of the fourth zone is 180°C -190°C, five-zone temperature of 180-190°C, head temperature of 180-200°C, host speed of 300-450 rpm, extruding and granulating to obtain the polypropylene flame-retardant material....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com