Imidazole ionic liquid, polyionic liquid and preparation methods and applications of the imidazole ionic liquid and the polyionic liquid

A technology of polyionic liquid and ionic liquid, which is applied in the field of designing ionic liquids, can solve problems such as the difficulty in separating catalysts and products, and achieve excellent catalytic effects, increased reaction rates, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation method of described ionic liquid comprises the steps:

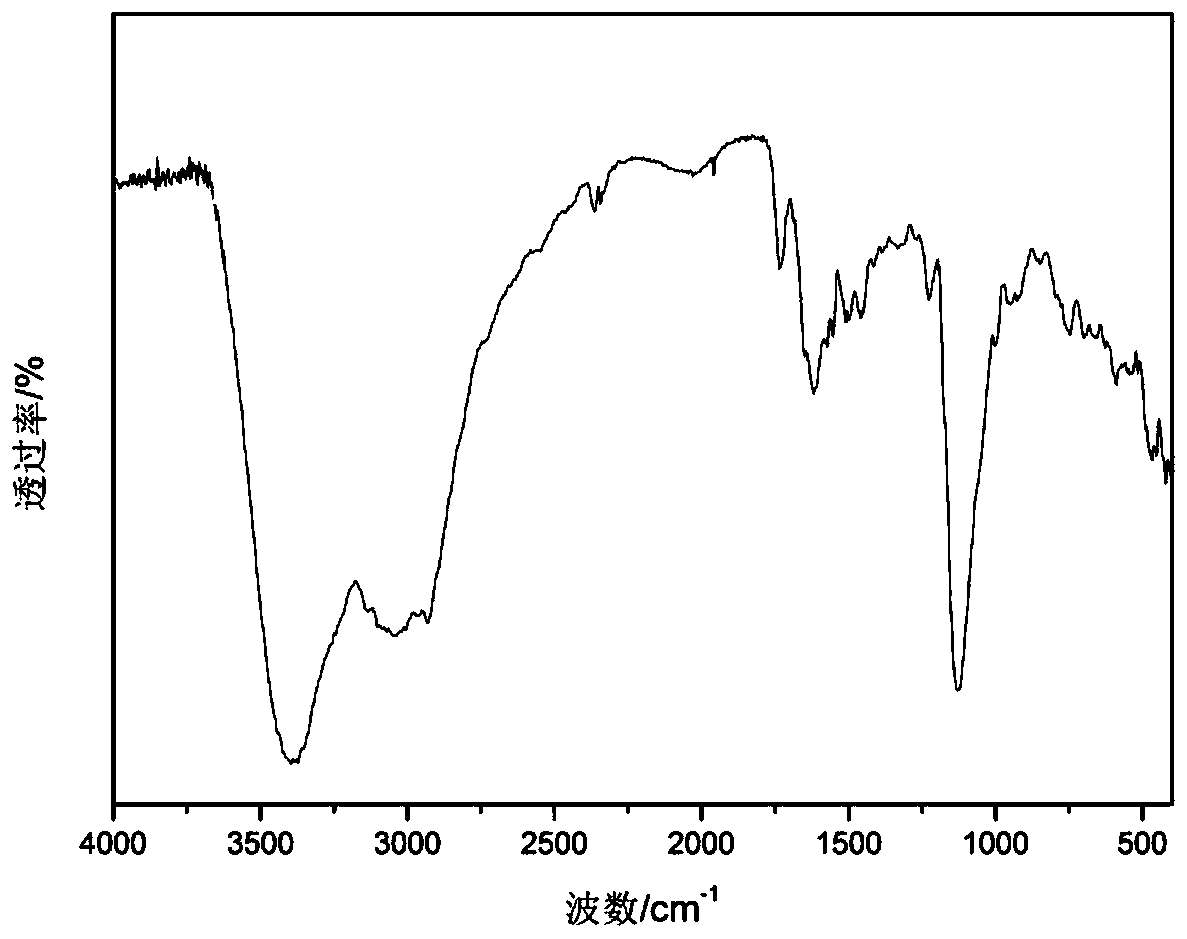

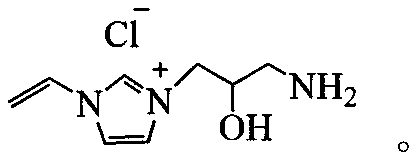

[0046]Add 1g of 1-vinylimidazole to 40ml of methanol solvent, pour it into a 100ml three-necked flask, then add 1g of (S)-1-amino-3-chloro-2-propanol hydrochloride, under a protective gas atmosphere, React at 70°C for 20h, after the reaction, cool to 25°C. The reactant was poured into a rotary evaporator for vacuum rotary evaporation to obtain 0.7 g of a crude product. 0.2ml of deionized water was added dropwise, and then solid sodium hydroxide was added to adjust the pH of the solution to 8; the upper layer solution was taken out, washed once with anhydrous acetonitrile, vacuum rotary evaporated, washed with tetrahydrofuran, and vacuum rotary evaporated. The obtained product is put into a drying box, kept at 60° C., and dried for 1 to 10 hours. This gives 1-vinyl-3-(1-amino-2-propanol)imidazole chloride.

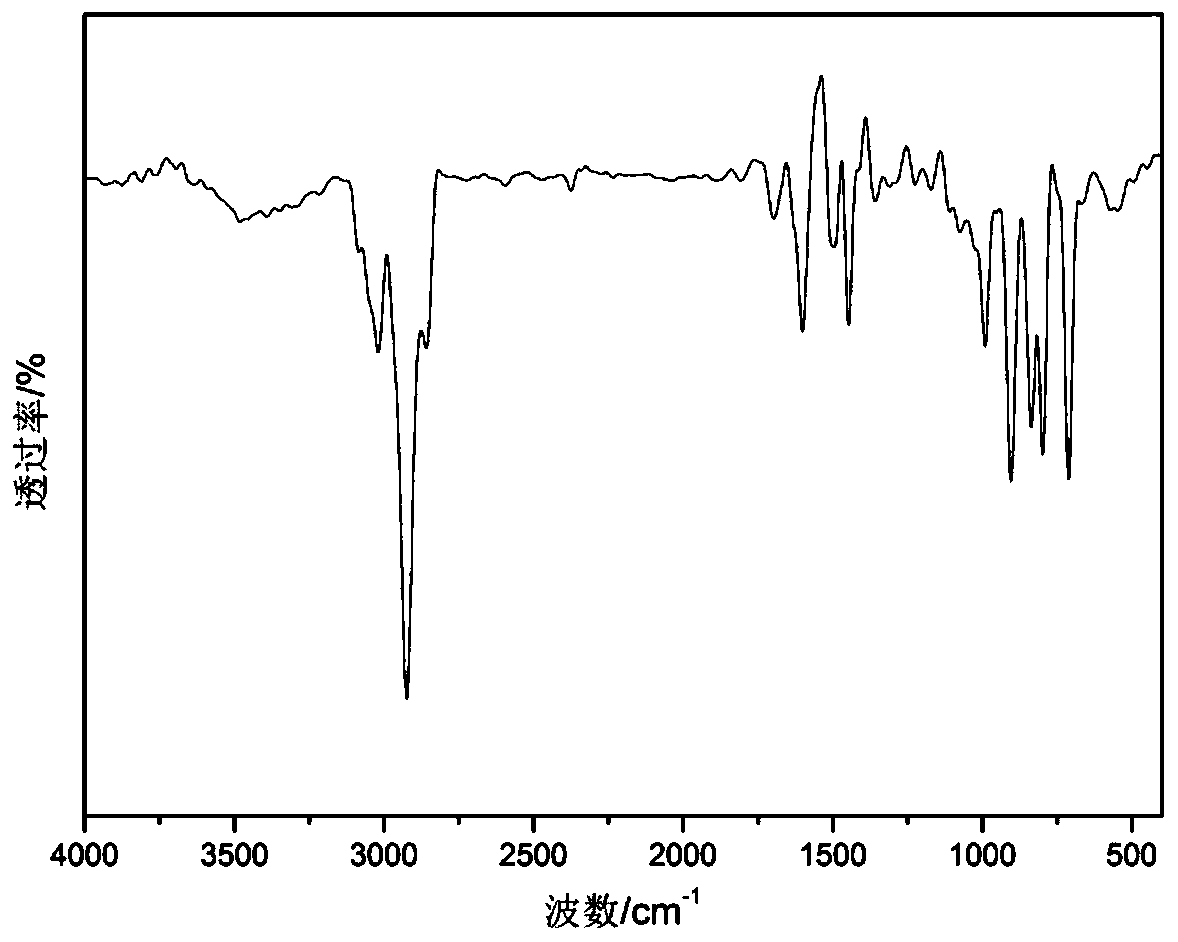

[0047] Put magneton, 50ml methanol, 0.05g azobisisobutyronitrile, 3g 1-vinyl-3-(1-amino-2-...

Embodiment 2

[0052] Add 2g of 1-vinylimidazole to 50ml of methanol solvent, pour it into a 100ml three-necked flask, then add 2.5g of (S)-1-amino-3-chloro-2-propanol hydrochloride, under a protective gas atmosphere , React at 75°C for 20h, after the reaction, cool to 25°C. This gives 1-vinyl-3-(1-amino-2-propanol)imidazole chloride. The product was taken out and poured into a rotary evaporator for vacuum rotary evaporation to obtain a crude product. Deionized water was added dropwise, and then titrated with sodium hydroxide to pH = 8. The upper layer solution was taken out, washed once with absolute ethanol, and after vacuum rotary evaporation, washed with tetrahydrofuran, and vacuum rotary evaporation. The obtained product was put into a drying oven, kept at 60° C., and dried for 7 hours. Obtain 1-vinyl-3-(1-amino-2-propanol)imidazole chloride

[0053] Put magneton, 50ml methanol, 0.05g azobisisobutyronitrile, 3g 1-vinyl-3-(1-amino-2-propanol) imidazole chloride and 3g divinylbenzene i...

Embodiment 3

[0055] The polyionic liquid obtained in Example 1 is used as a catalyst to catalyze propylene oxide and carbon dioxide to synthesize propylene carbonate in a high-temperature and high-pressure stainless steel reactor. In reaction conditions: catalyst 100mg, propylene oxide 2g, carbon dioxide initial pressure at 1.2MPa, When the temperature is 100°C, after 5 hours of reaction, the conversion efficiency of propylene oxide is 75%. After the reaction, the product and the catalyst were taken out, and the system was filtered under reduced pressure, and a white solid polyionic liquid was obtained on the filter paper, which was the catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com