A kind of preparation method of light-weight high-strength humidity control material

A humidity-conditioning material and high-strength technology, which is applied in the field of preparation of light-weight and high-strength humidity-conditioning materials, can solve problems such as the blank stage of perlite utilization, and achieve excellent humidity-conditioning performance, strong dehumidification ability, and improved humidity-conditioning performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

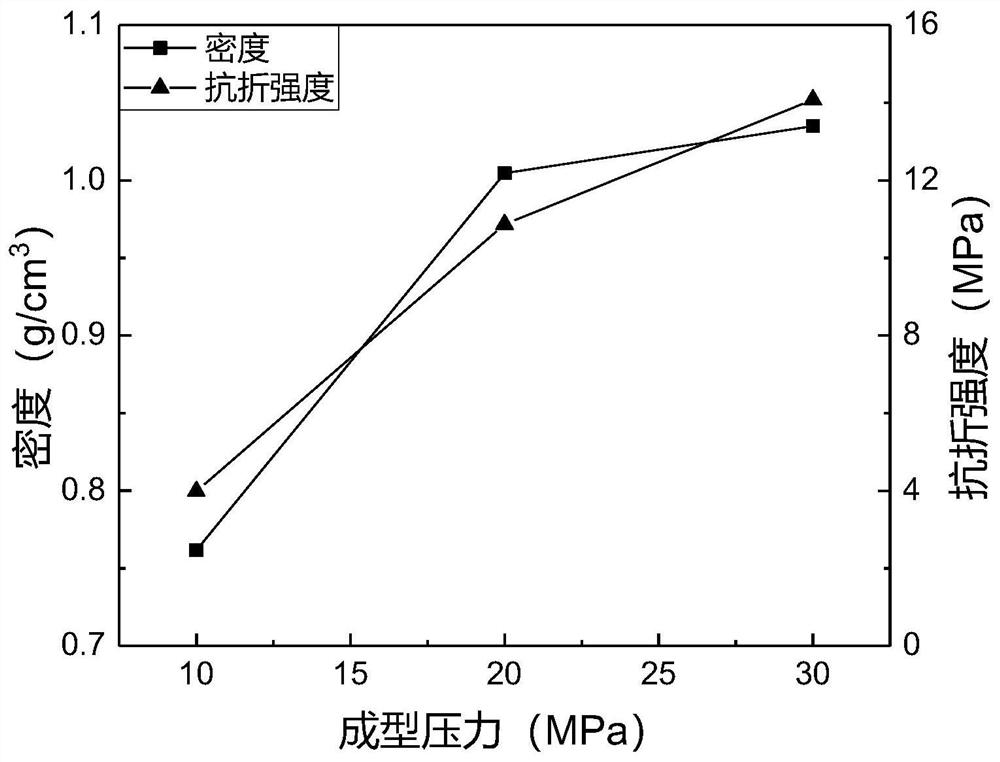

[0028] In this embodiment 1, the molding pressure is used as the main variable, and the influence of the molding pressure on the flexural strength and density of the light-weight, high-strength humidity-controlling material cured product is explored and analyzed. Perlite is firstly measured by mass percentage: calcium hydroxide=68%:32%, satisfying that the calcium-silicon ratio is 0.5, and calcium chloride is not used in this embodiment. Then measure the deionized water of 5-50% mass percent of the total weight of perlite and calcium hydroxide, mix it evenly, and press it under the FW-4 type desktop powder tablet press, the molding pressure is 10-30MPa, demoulding The final sample is put into a hydrothermal kettle for hydrothermal curing, the hydrothermal temperature is 200°C, and the hydrothermal time is 12h. The cured sample (40mm×15mm×6mm) was dried in an oven at 60°C for 24 hours to obtain a light-weight and high-strength humidity-adjusting material cured product, which wa...

Embodiment 2

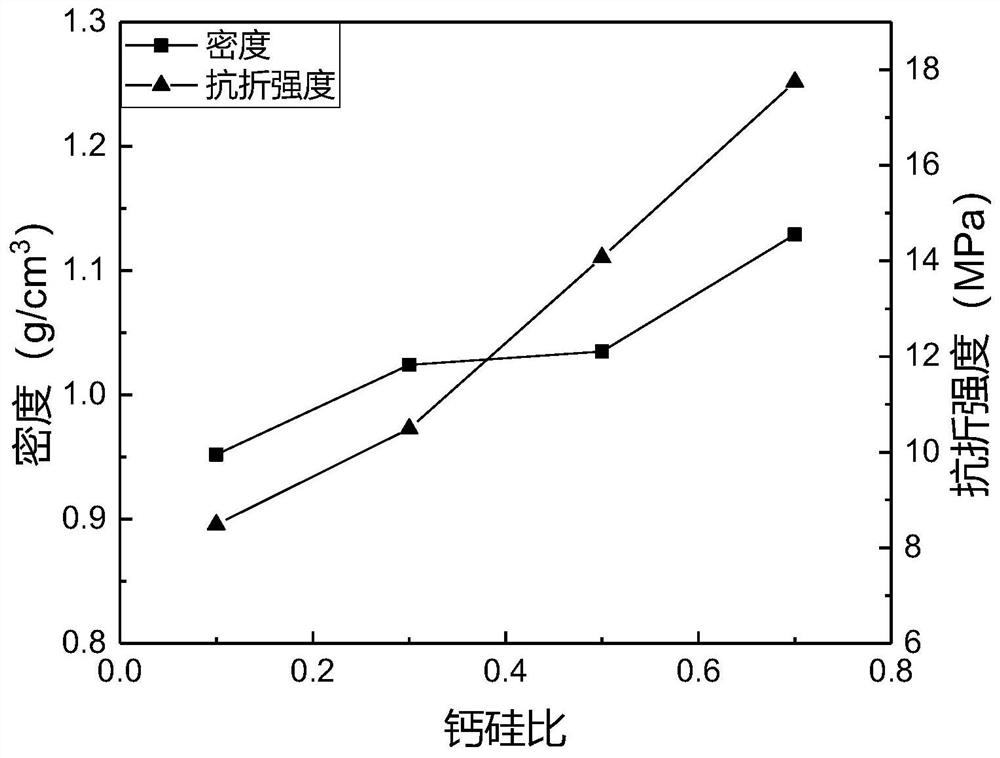

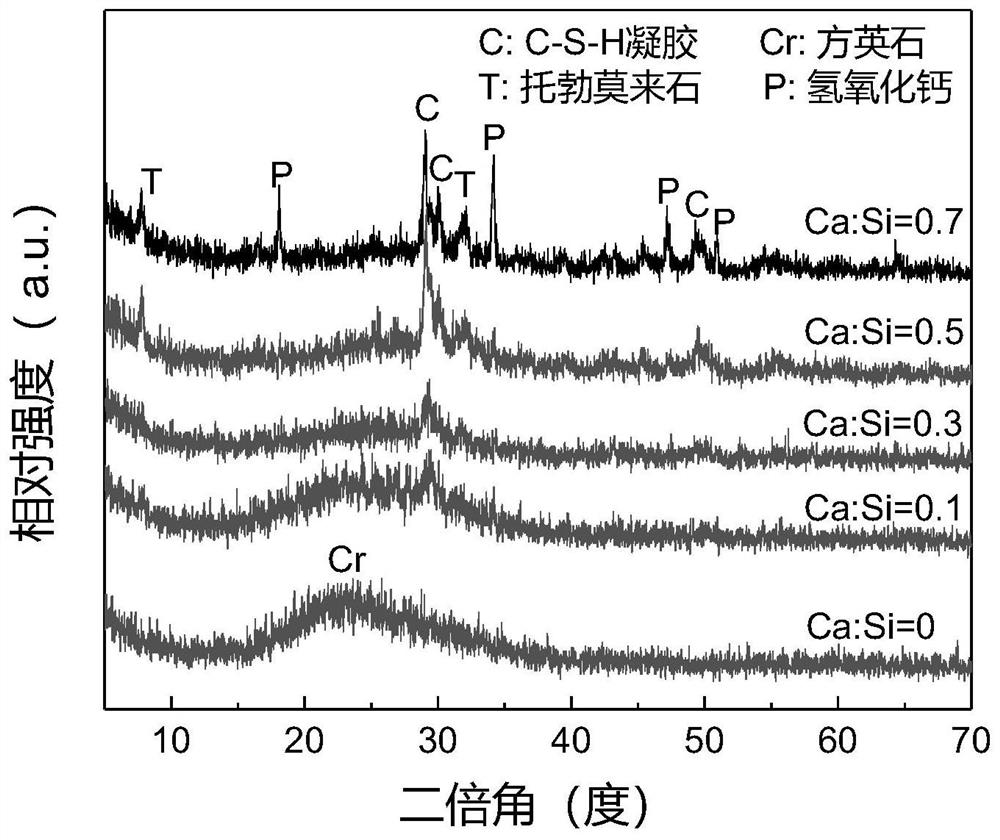

[0031] In this embodiment, the calcium-silicon ratio is used as the main variable, and the influence of different silicon-calcium ratios on the flexural strength and density of the cured product is explored and analyzed. Weigh perlite and calcium hydroxide according to calcium-silicon ratio = 0.1-0.7, without using calcium chloride, then measure deionized water of 5-50% by mass of the total weight of perlite and calcium hydroxide, mix well Press and form under the FW-4 desktop powder tablet press, the forming pressure is 20MPa, and the sample after demoulding is put into a hydrothermal kettle for hydrothermal curing, the hydrothermal temperature is 200°C, and the hydrothermal time is 12h. The cured sample (40mm×15mm×6mm) was dried in an oven at 60°C for 24 hours to obtain a cured product, which was obtained after testing figure 2 The flexural strength-density change graph of cured products with different calcium-silicon ratios is shown.

[0032] from figure 2It can be seen...

Embodiment 3

[0036] In Example 3, the amount of water added was used as the main variable, and the influence of different amounts of water added on the flexural strength of the cured product was explored and analyzed. Weigh perlite and calcium hydroxide according to calcium-silicon ratio = 0.5, then measure deionized water of 5-50% by mass of the total weight of perlite and calcium hydroxide, mix it evenly and press Press molding under the tablet machine, the molding pressure is 20MPa, the demoulded sample is put into a hydrothermal kettle for hydrothermal curing, the hydrothermal temperature is 200°C, and the hydrothermal time is 12h. The cured sample (40mm×15mm×6mm) was dried in an oven at 60°C for 24 hours to obtain a cured product, which was obtained after testing Figure 5 The flexural strength-density change graph of cured products with different water additions is shown.

[0037] from Figure 5 It can be seen that as the amount of water added increases, the flexural strength of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com