Method for preparing automatic humidity control material from calcium chloride

A humidity control material, calcium chloride technology, applied in the direction of aluminum silicate, silicate, etc., can solve the problems of lack of strength, affect the effect of automatic humidity control, and cannot directly use the building wall alone, etc., to achieve moisture release Strong ability, conducive to humidity control performance, superior effect of automatic humidity adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The mixture of waste glass and limestone selected through a 100-mesh sieve and dried is expressed in cg (the mass percentage of waste glass and limestone is 50%:50%).

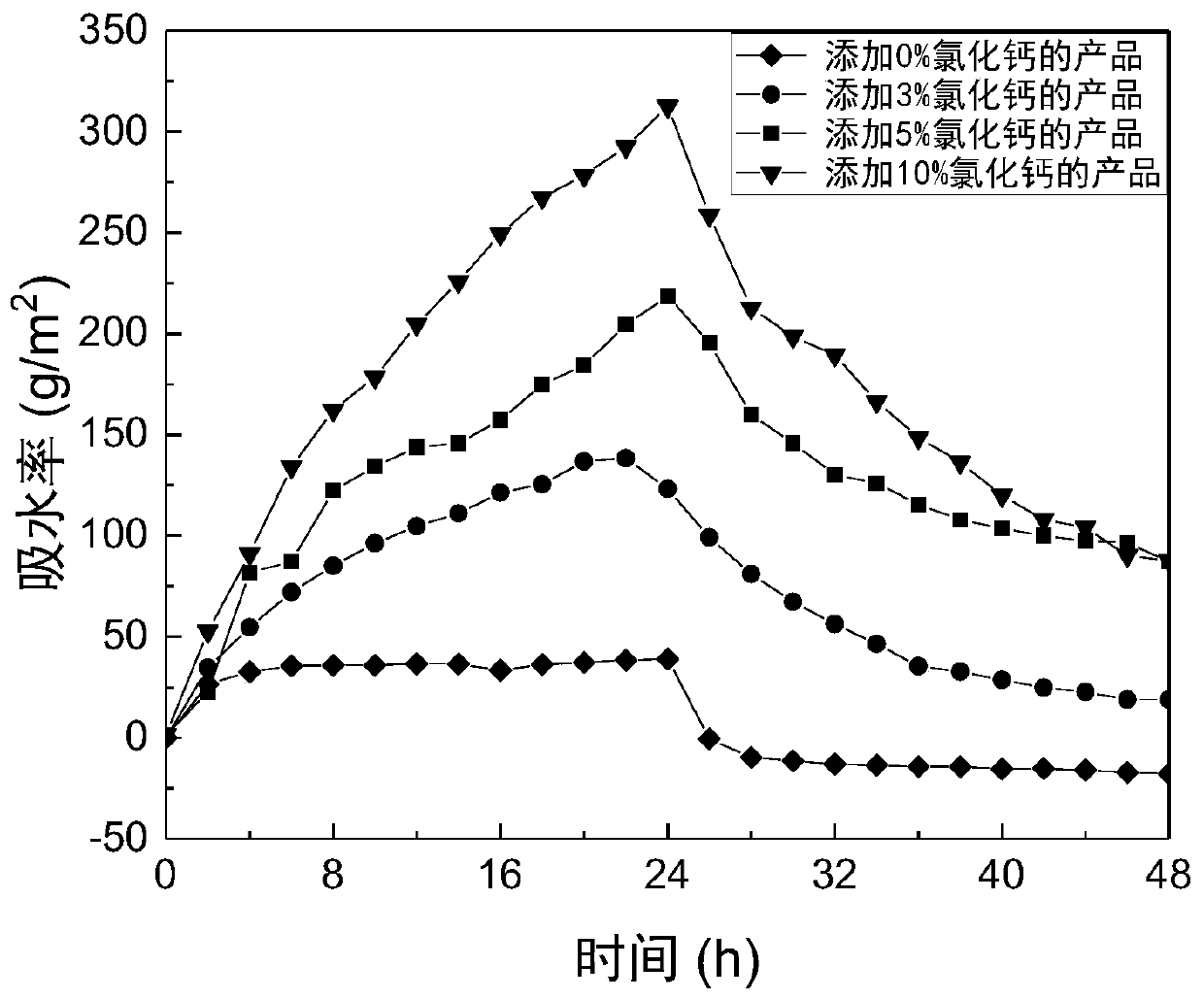

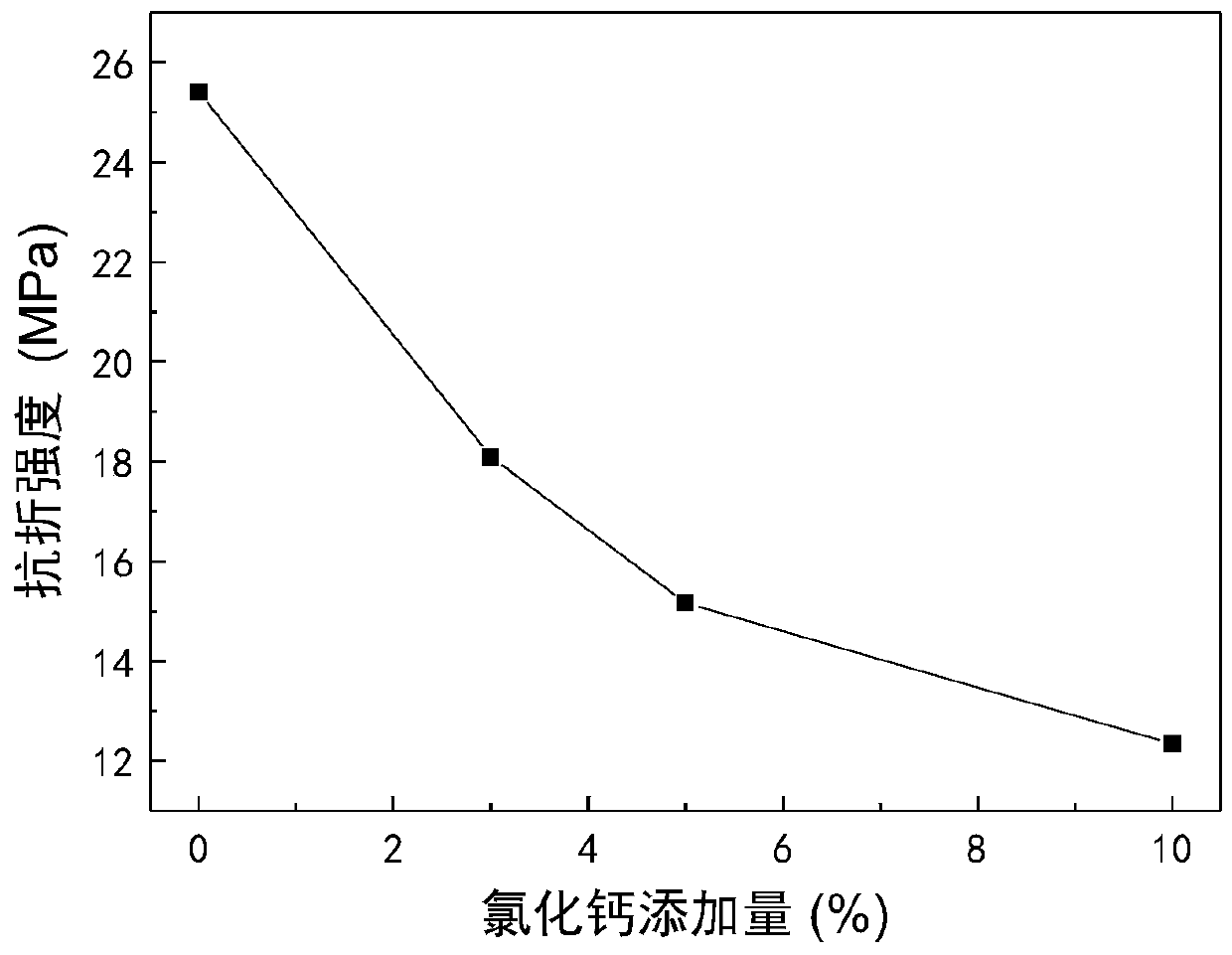

[0024] In this embodiment 1, the calcium chloride content is used as a variable, and the influence of different calcium chloride content on the humidity control performance of the cured product is explored and analyzed. First, add an appropriate amount of calcium chloride (1% to 15%) in the cg, and then additionally measure 5% to 10% of the total weight of water or sodium hydroxide solution (concentration is 2 to 5mol / L), and mix it according to the above ratio After the raw materials are mixed evenly, they are pressed and formed under the FW-4 desktop powder tablet press (the forming pressure is 30MPa), and the demolded samples are put into a hydrothermal kettle for hydrothermal curing (temperature 200°C, time 15h). The cured sample (40mm×15mm×6mm) was dried in an oven at 80°C for 24 hours to obtain a c...

Embodiment 2

[0033] Taking the content of calcium chloride as a variable, observe the influence of its change on the humidity control performance, and discuss the effect of calcium chloride on the automatic humidity control material.

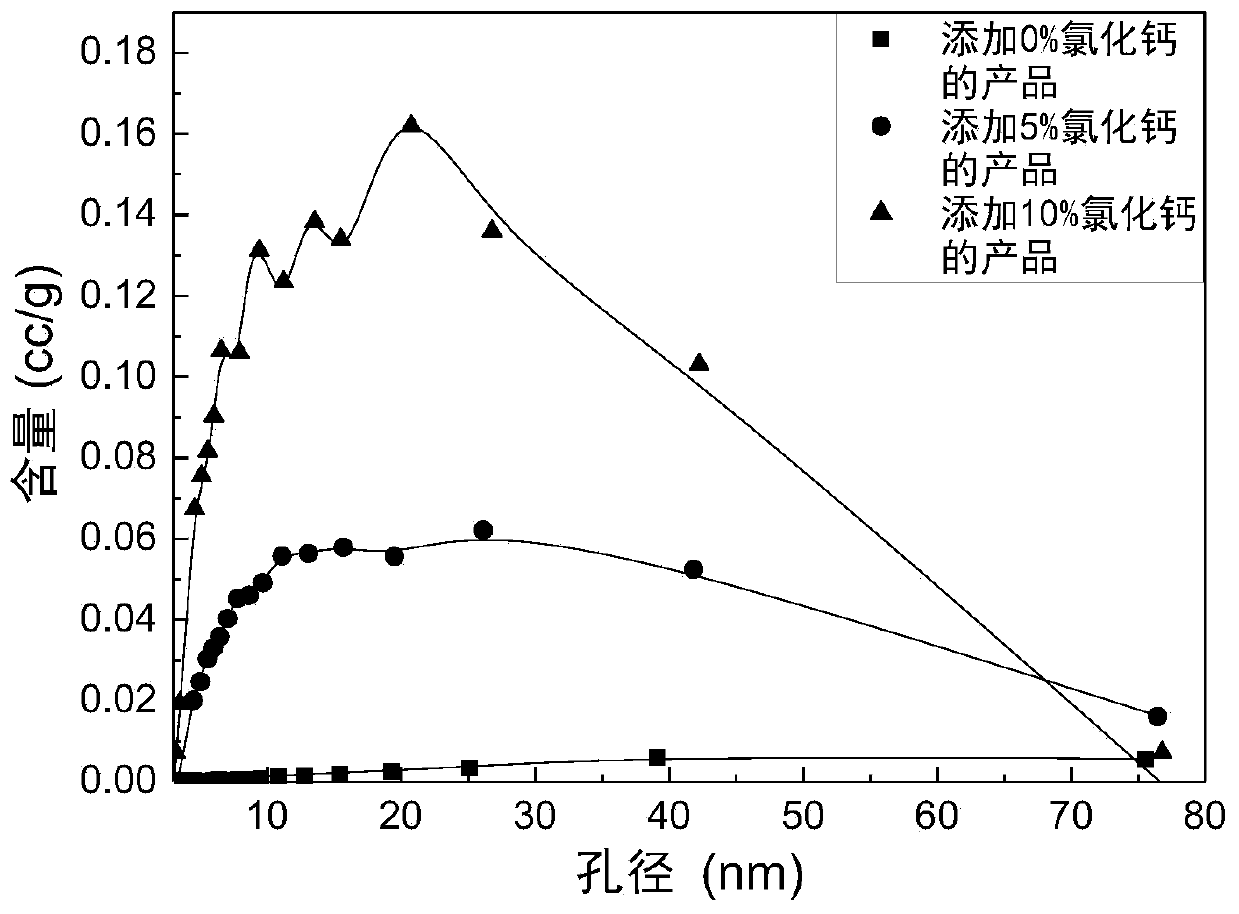

[0034] According to the analysis of the types of isotherm adsorption curves classified by the International Union of Chemistry (IUPAC) by Nobuji Watari, it is found that materials with IV-type isotherm adsorption curves are more suitable as humidity control materials; and using Kelvin and related formulas, it can be deduced that the pore size is between 3.2 and Materials between 7.4nm can automatically maintain the indoor relative humidity at 40% to 70%, which is the most comfortable range for the human body.

[0035] Using Example 1, a cured product (sample) was obtained. Experimental results such as Figure 3-5 shown, from image 3 It can be found that the above theory is indeed well met. As the calcium chloride content continues to increase, the mesopor...

Embodiment 3

[0040] In this example, the content of calcium chloride is selected as 10%, and the mass ratio of waste glass to limestone is used as a variable to explore and analyze the influence of different calcium chloride contents on the humidity control performance of the cured sample.

[0041] Firstly, a mixture cg of different mass ratios of waste glass to limestone (2:8-6:4) is prepared, and the mass percentage is converted into waste glass:limestone=20%-60%:40%-80%. Then mix with calcium chloride: cg=1:9, and then additionally take 5% to 10% of the total weight of water or sodium hydroxide solution (concentration is 2 to 5mol / L), and mix the raw materials according to the above ratio After homogeneity, it is pressed and formed under the FW-4 desktop powder tablet press (forming pressure is 30MPa), and the sample after demoulding is put into a hydrothermal kettle for hydrothermal curing (temperature 200°C, time 15h). After the cured sample (40mm×15mm×6mm) was dried in an oven at 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com