Hierarchically recycling method of waste aluminum etching liquid

An aluminum etching, liquid technology, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, inorganic chemistry, etc., can solve the problems of ineffective utilization of acetic acid and nitric acid, time-consuming, waste of resources, etc., to reduce decomposition effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

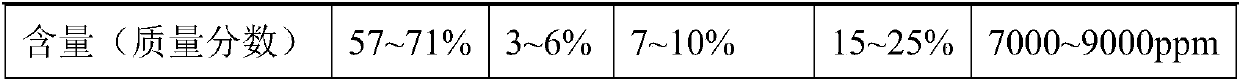

[0032] Get a certain TFT-LCD factory waste aluminum etching solution, its chemical composition is as follows:

[0033] chemical composition h 3 PO 4

HNO 3

CH 3 COOH

h 2 o

Al Content (mass fraction) 57~71% 3~6% 7~10% 15~25% 7000~9000ppm

[0034] According to the following steps, the waste aluminum etching solution is graded and recovered:

[0035] (1) Add 300mL of waste aluminum etching solution into a distillation flask, add a magnetic stirrer, and conduct vacuum distillation with a continuous water replenishment rate of 1mL / min and a distillation temperature of 90°C. Condensate and recover the mixture of nitric acid and acetic acid in the distillate, and keep the solution in the distillation bottle.

[0036] (2) When phosphoric acid is cooled to below 15°C, 5% mass fraction of phosphoric acid seed crystals are added to slowly crystallize, so as to prevent metal ions from being difficult to remove due to too fast crystalliza...

Embodiment 2

[0040] Get a certain TFT-LCD factory waste aluminum etching solution, its chemical composition is as follows:

[0041] chemical composition h 3 PO 4

HNO 3

CH 3 COOH

h 2 o

Al Content (mass fraction) 57~71% 3~6% 7~10% 15~25% 7000~9000ppm

[0042] According to the following steps, the waste aluminum etching solution is graded and recovered:

[0043] (1) Add 300mL waste aluminum etching solution into a distillation bottle, add a magnetic stirrer, and conduct vacuum distillation with a continuous water replenishment rate of 1.5mL / min and a distillation temperature of 80°C. Condensate and recover the mixture of nitric acid and acetic acid in the distillate, and keep the solution in the distillation bottle.

[0044] (2) When phosphoric acid is cooled to below 15°C, add perfluorosulfonic acid, the amount of perfluorosulfonic acid accounts for 5.6% of the mass fraction of phosphoric acid solution collected, add 3% mass fraction of ph...

Embodiment 3

[0048] Get a certain TFT-LCD factory waste aluminum etching solution, its chemical composition is as follows:

[0049] chemical composition h 3 PO 4

HNO 3

CH 3 COOH

h 2 o

Al Content (mass fraction) 57~71% 3~6% 7~10% 15~25% 7000~9000ppm

[0050] According to the following steps, the waste aluminum etching solution is graded and recovered:

[0051] (1) Add 300mL of waste aluminum etching solution into a distillation flask, add a magnetic stirrer, and conduct vacuum distillation with a continuous water replenishment rate of 0.5mL / min and a distillation temperature of 100°C. Condensate and recover the mixture of nitric acid and acetic acid in the distillate, and keep the solution in the distillation bottle.

[0052] (2) When phosphoric acid is cooled to below 15°C, add fluosilicic acid, the amount of fluosilicic acid added accounts for 5.6% of the mass fraction of the phosphoric acid solution collected, and 4% mass fraction of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com