A Multistage Passive Bending Mechanism Based on the Crossed Reeds at the Free Ends of the Curved Surface

A bending mechanism and free end technology, applied in the field of multi-stage passive bending mechanism, can solve problems such as passive deformation of bionic fish, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will now be further described in conjunction with the embodiments and accompanying drawings:

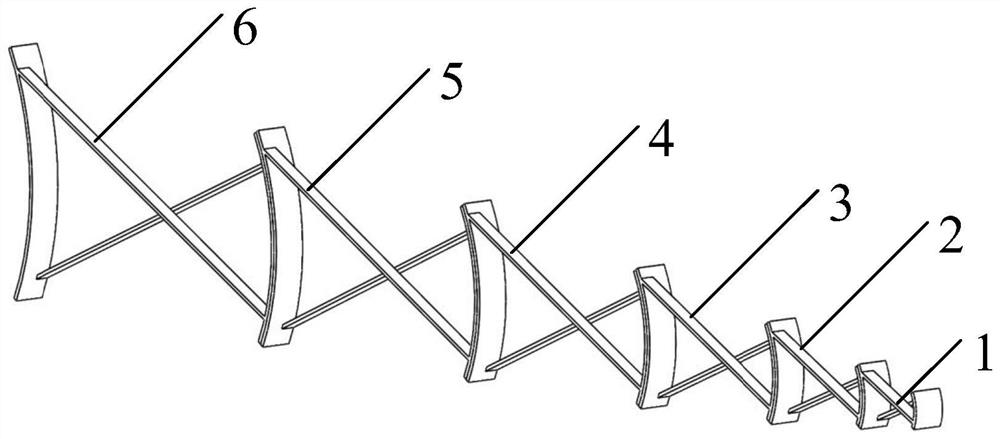

[0028] This embodiment is a six-stage passive bending mechanism, including the No. 1 cross-reed unit, the No. 2 cross-reed unit, the No. 3 cross-reed unit, the No. 4 cross-reed unit, and the No. 5 cross-reed unit and Cross Reed Unit No. 6.

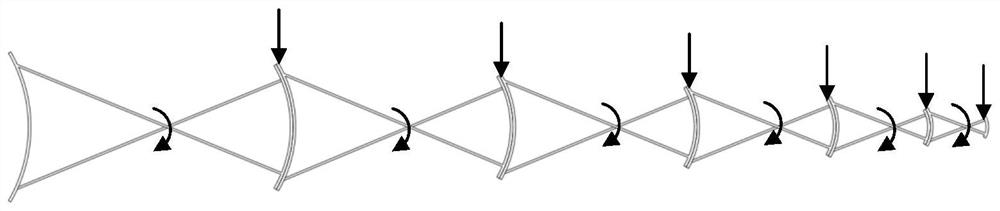

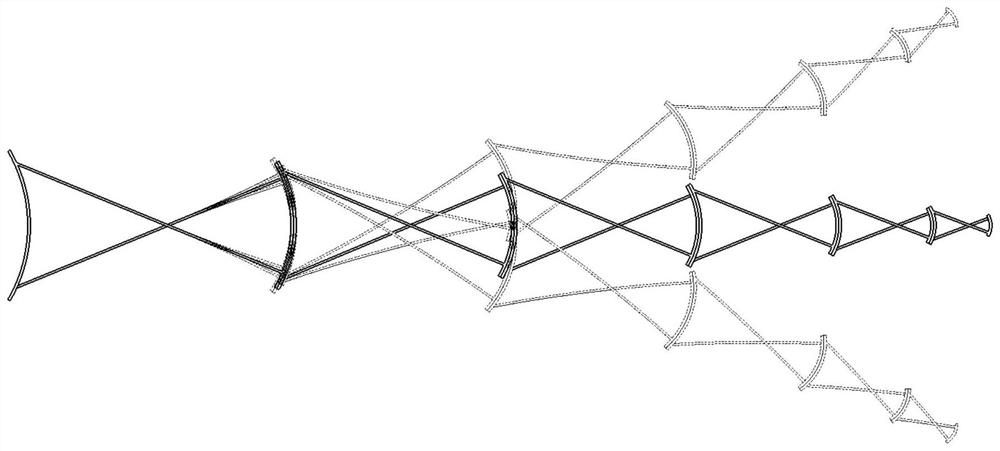

[0029] The multi-stage passive bending mechanism based on the cross-reed is mainly composed of cross-reed units with different sizes. The cross-reed unit is composed of two arc-surface free ends and a cross-reed connecting the two arc-surface free ends. The size of the specific cross reed is determined according to the line type of the specific multi-stage passive bending mechanism. By changing the combination of different bending units, the stiffness and size of each stage of the entire multi-stage bending mechanism can be controlled at the same time, so that the precise control can be achieved. The stiffness distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com