A kind of wear-resistant sandpaper and its production process

A production process and technology for sandpaper, applied in the field of sandpaper manufacturing, can solve problems such as the end of the service life of sandpaper, the inability of abrasives to fully function, and the poor waterproof ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

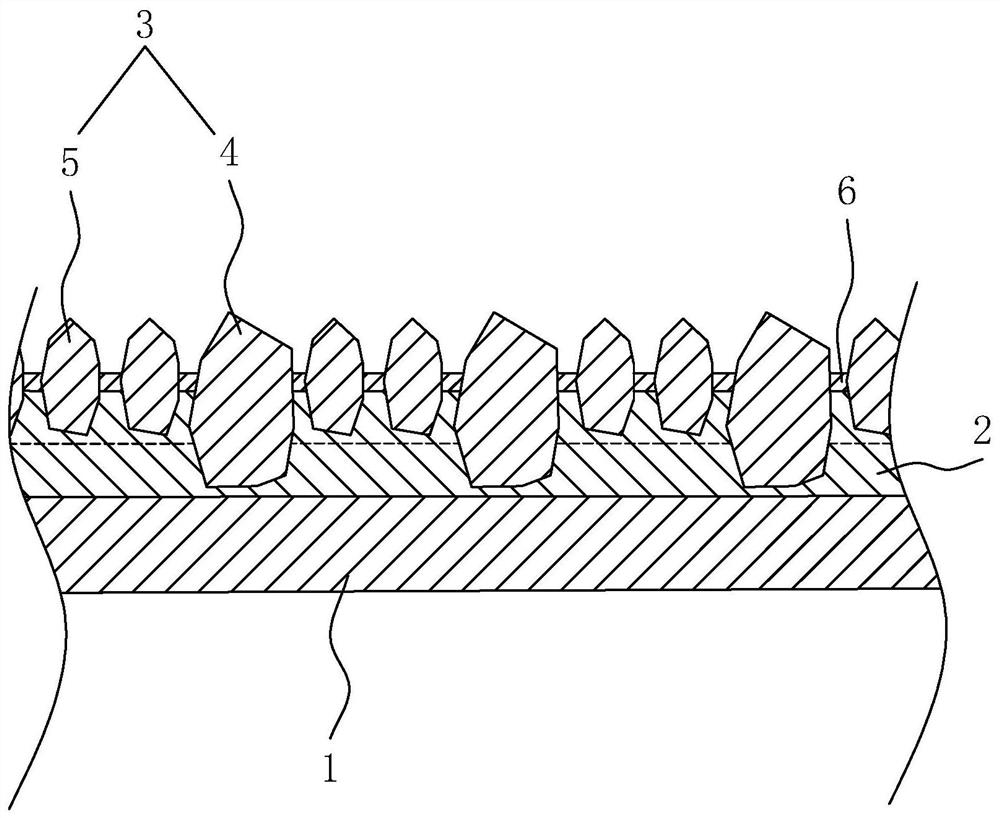

[0043] refer to figure 1 , is a kind of wear-resistant sandpaper disclosed by the present invention, which successively includes a matrix layer 1, an adhesive layer 2, and an abrasive layer 3, and the abrasive layer 3 includes a first abrasive grain 4 and a mesh number The second abrasive grain 5 which is smaller than the first abrasive grain 4 and placed on the adhesive layer 2 in the gap between the first abrasive grains 4 is also coated with an anti-blocking layer 6 above the adhesive layer 2 . Wherein, the adhesive layer 2 is composed of polyvinyl alcohol water-based adhesive coated on the surface of the base layer 1 (one of acrylic water-based adhesive, polyurethane water-based adhesive, and epoxy water-based adhesive can also be selected. species), the anti-blocking layer 6 is formed by coating zinc stearate on the surface of the adhesive layer 2.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com