A solid-liquid separation method for oily sediment recovery and treatment

A technology of solid-liquid separation and recovery treatment, applied in separation methods, cleaning methods using liquids, solid separation, etc., can solve the problems of carcinogenicity and poisoning of staff, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

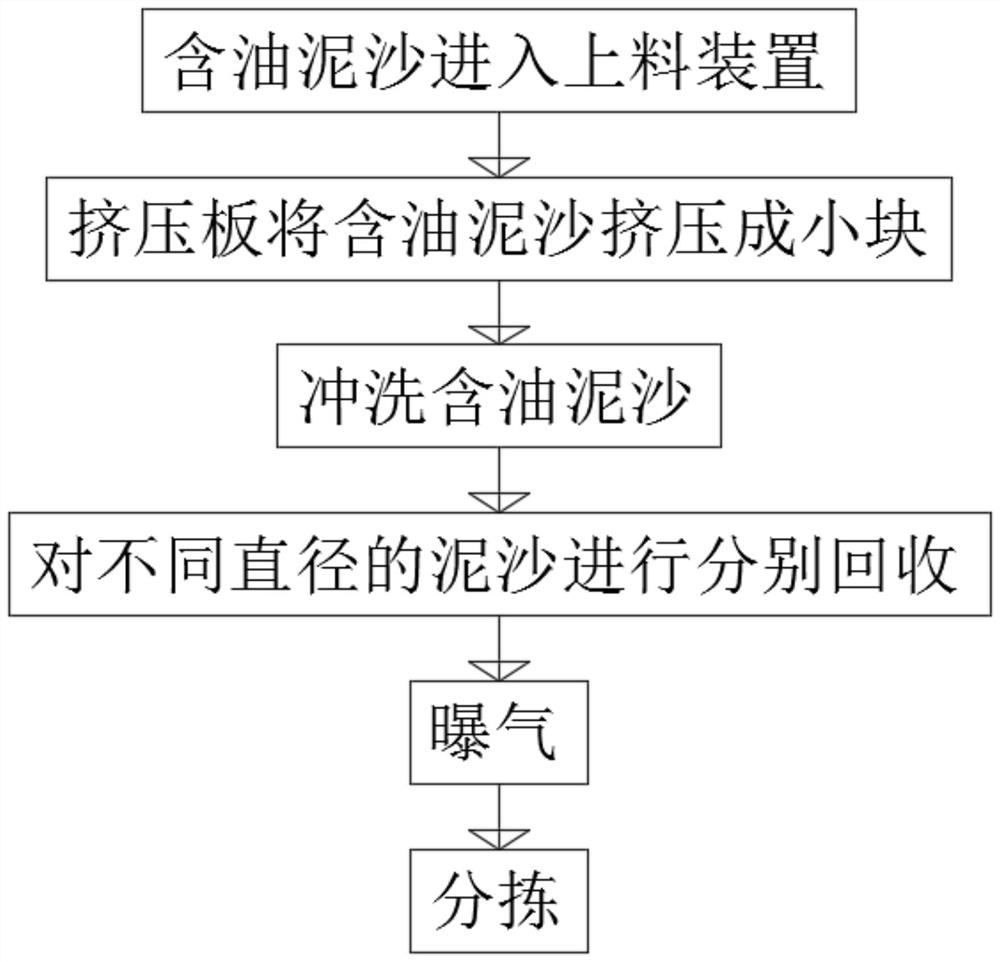

[0053] A solid-liquid separation method for oily sediment recovery treatment, the operation steps of the solid-liquid separation method are:

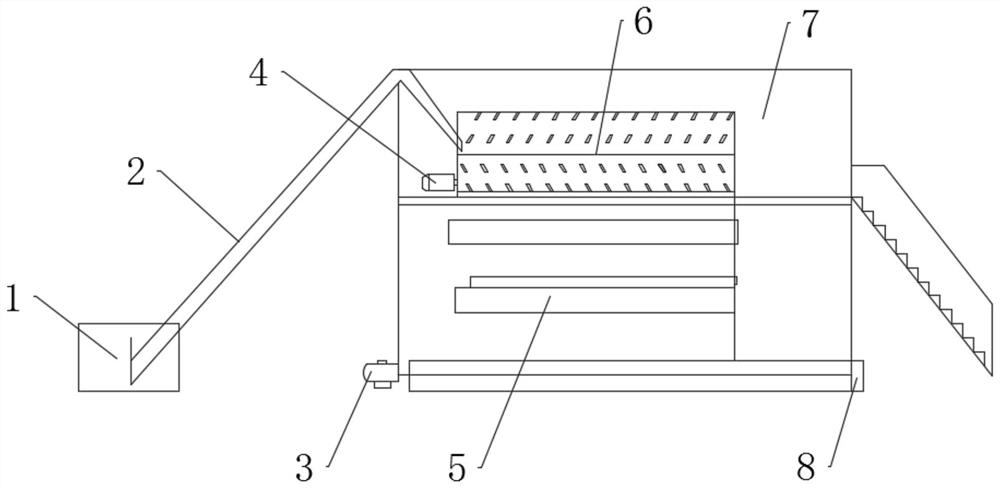

[0054] Step 1. The staff first places the untreated oily sediment on the conveyor belt, and the conveyor belt moves it into the feeding device 1 through the feeding port 101;

[0055] Step 2. Please refer to Figure 4 , the staff starts the extruding plate 105, extrudes the oily silt through the breaking plate 102, squeezes the large piece of oily silt into small pieces and pushes them into the rotating cage 6;

[0056] Step 3: The staff starts the rotating cage 6 to start rotating, and washes the oily sediment in the rotating cage 6 through the water pump 3;

[0057] Step 4, the staff controls the switch of the electric telescopic rod 602 according to the particle diameter of the solid, and adjusts the positions of the second filter plate 604 and the third filter plate 605;

[0058] Step 5, collect the particles of different diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com