Heat-not-burning smoke formation product and preparation method thereof

A heat-not-burn and smoke-generating product technology, applied in the field of tobacco, can solve problems such as insufficient smoke volume and aroma, poor sensory experience for consumers, and miscellaneous firewood odor, etc., to achieve changeable styles, good aroma, and smoke Ample effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A heat-not-burn smoking product, comprising 7 parts of tobacco leaf powder (composed of upper tobacco leaf powder, middle tobacco leaf powder, and lower part tobacco leaf powder in a weight ratio of 1:3:1), 2 parts of tobacco stem powder, 1 part of green tea powder, 1 part of 1 part Porous Ceramic Powder and 1 part Tobacco Extract Blend.

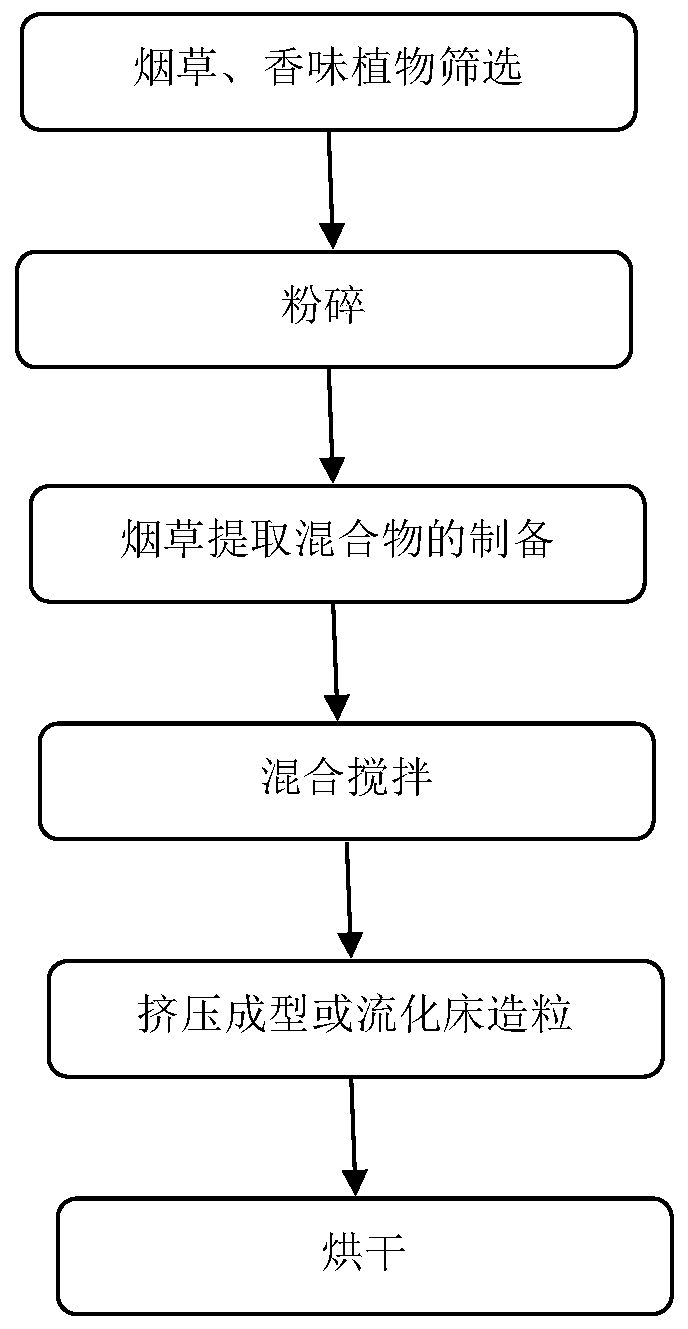

[0028] Its preparation method comprises the following steps:

[0029] Select 7 parts of tobacco leaves (composed of upper tobacco leaves, middle tobacco leaves, and lower tobacco leaves in a weight ratio of 1:3:1), 2 parts of tobacco stems, and 1 part of green tea and mix them evenly; wherein the mixed plant materials are put into a grinder to pulverize, and the 80-mesh sieve to obtain the mixed powder, and set aside; the tobacco is pulverized, heated and refluxed for extraction, and the obtained extract is fractionated by a molecular distillation apparatus, and the rectified tobacco aroma components are collected as the tobacco extra...

Embodiment 2

[0031] A heat-not-burn smoking product, comprising 7 parts of tobacco leaf powder (consisting of upper tobacco leaf powder, middle tobacco leaf powder, and lower tobacco leaf powder in a weight ratio of 1:3:1), 1 part of tobacco stem powder, and 1 part of Sanqi peduncle powder , 1 part macroporous resin and 1.35 parts tobacco extract mixture.

[0032] Its preparation method comprises the following steps:

[0033] Select 7 parts of tobacco leaves (composed of upper tobacco leaves, middle tobacco leaves, and lower tobacco leaves in a weight ratio of 1:3:1), 1 part of tobacco stems, and 1 part of Panax notoginseng pedicel and mix them evenly; put the mixed plant raw materials into a grinder to pulverize, Pass through an 80-mesh sieve to obtain a mixed powder for later use; the tobacco is pulverized, heated and refluxed for extraction, and the obtained extract is fractionated by a molecular distillation apparatus, and the rectified tobacco aroma components are collected as the tob...

Embodiment 3

[0035] A heat-not-burn smoking product, comprising 5 parts of tobacco leaf powder (consisting of upper tobacco leaf powder, middle tobacco leaf powder, and lower tobacco leaf powder in a weight ratio of 1:3:1), 2 parts of tobacco stem powder, and 1 part of tortoise flower powder , 2 parts zeolite powder and 1.44 parts tobacco extract mixture.

[0036] Its preparation method comprises the following steps:

[0037]Select 5 parts of tobacco leaves (composed of upper tobacco leaves, middle tobacco leaves, and lower tobacco leaves in a weight ratio of 1:3:1), 2 parts of tobacco stems, and 1 part of tortoise flower and mix them evenly; put the mixed plant raw materials into a grinder to pulverize, Pass through an 80-mesh sieve to obtain a mixed powder for later use; the tobacco is pulverized, heated and refluxed for extraction, and the obtained extract is fractionated by a molecular distillation apparatus, and the rectified tobacco aroma components are collected as the tobacco extra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com