Transparent flexible conductive core board for back-contact large-size battery assembly and preparation method thereof

A technology of battery components and flexible conduction, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems such as the difficulty in applying back-contact large-size solar cell components, the inability to develop double-sided back-contact cell components, large flexible transparent conductive films, etc. , achieving high stability and UV absorption coefficient, achieving flexibility and transparency, and rich raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

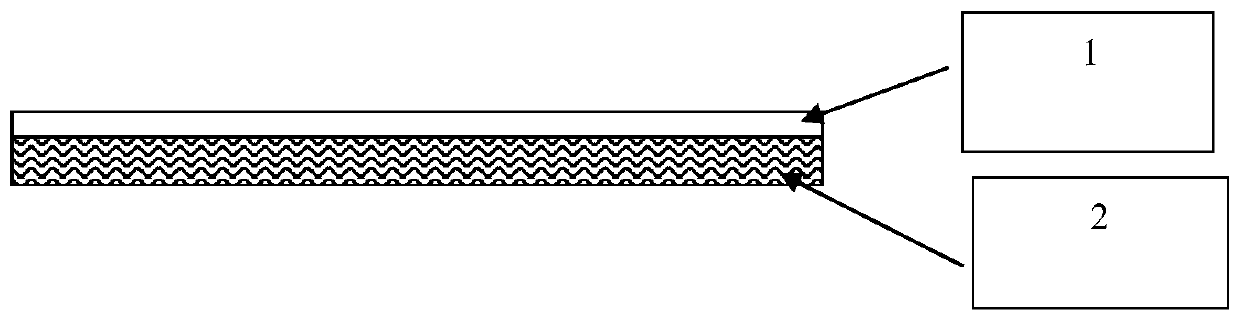

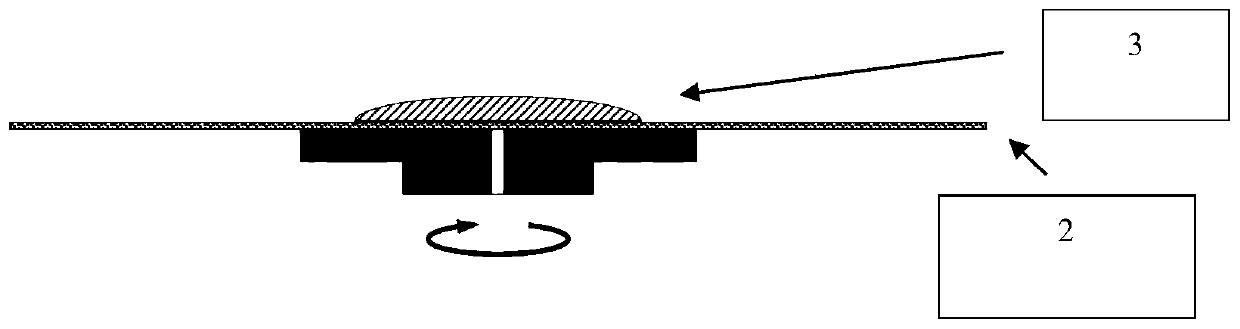

[0025] When this embodiment is implemented by spin coating, the polymer film substrate 2 is cleaned first, and then placed on the loading tray of the spin coating machine, and the loading tray is evacuated to prevent the film substrate from slipping during spin coating. Then the sol of certain volume and solid content is dropped on film base 2 (see figure 2 ), the amount of sol 3 can be 90-160ml / m 2 , the solid content of sol 3 can be 0.5%-3.5%. Use the set parameters for spin coating. The coating is divided into low speed gear 300-1000 rpm and high speed gear 2500-5500 rpm. The coating time of high and low speed gear can be 5s-60s, and the low speed gear is used for sol The high-speed gear is used to control the uniformity of film coating. By controlling the coating time of this gear, the thickness of film coating can be controlled within the range of 300-800nm. After spin coating, the films were dried at 50°C and then at 120°C for 6 minutes and then baked for 20 minutes. ...

Embodiment 2

[0027] When this embodiment is implemented by pulling coating, the polymer film substrate is first cleaned, and a mask plate is pasted and fixed on the back. Several polymer film substrates 2 are subsequently immersed in the coating sol 3 simultaneously (see Figure 4 ). Do not touch each other between the substrates, so as not to affect the film coating quality. Control the dipping time and pulling speed to control the thickness of the coating. The dipping time can be 3-15min, the dipping speed can be 50-150mm / s, and the pulling speed can be 10-60mm / s. After coating the pull-up film, the film was dried at 50° C. and 120° C. for 6 minutes and then baked for 20 minutes. Then press a certain pattern (see image 3 ) performing laser etching on the conductive film, and then purging with nitrogen gas and removing the mask plate after etching to obtain a flexible transparent conductive circuit core board. Please add the yellow part parameters.

Embodiment 3

[0029] In this embodiment, when the transparent and flexible conductive film is prepared by spin-coating fluorine-doped tin dioxide sol, the sol is dispersed in ethanol solvent, and the solid content of the sol can be 0.5%-3%. Before coating, the sol needs to be ultrasonically dispersed in ice water. While improving the dispersibility of the sol particles, it is also necessary to avoid a large amount of volatilization of the solvent caused by ultrasonic overheating, which will cause changes in the solid content of the sol and the resulting uneven performance of the conductive film. The temperature of ultrasound is controlled below 10°C, and the time of ultrasound is controlled within 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com