Tool feature recognition method based on deep learning

A feature recognition and deep learning technology, applied in the field of tool feature recognition based on deep learning, can solve the problems of poor practicability and achieve good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific steps of the tool feature recognition method based on deep learning of the present invention are as follows:

[0032] Step 1. Tool feature extraction: First, it is necessary to construct the input data of the tool feature extraction network, intercept the three views of the tool head with a resolution of 256×256, and process it into a binary grayscale pixel matrix to obtain 256×256× The structure information matrix of 3:

[0033] Y str =[[Y M,str ],[Y S,str ],[Y T,str ]] (1)

[0034] In the formula, Y str It is a pixel matrix of tool structure information, its dimension is 256×256×3, including three pixel matrices Y of front view, side view and top view M,str , Y S,str , Y T,str .

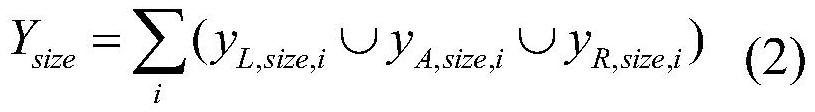

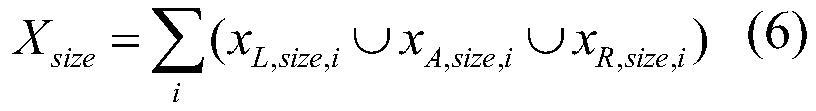

[0035] Construct the tool size information matrix, that is, take the binary representation of each size data of the tool (64-bit floating point type) as the tool size vector, classify it by length, angle, diameter, and sort by size to form a matrix with a dimension of 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com