Combined gas-liquid separator structure

A gas-liquid separator and cylinder technology, which is applied in the field of air-conditioning components, can solve the problems that affect the smooth progress of debugging or maintenance, cannot add refrigerant or lubricating oil, and the liquid level is not easy to maintain uniformity, etc., so as to improve production or maintenance efficiency , Simple structure, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

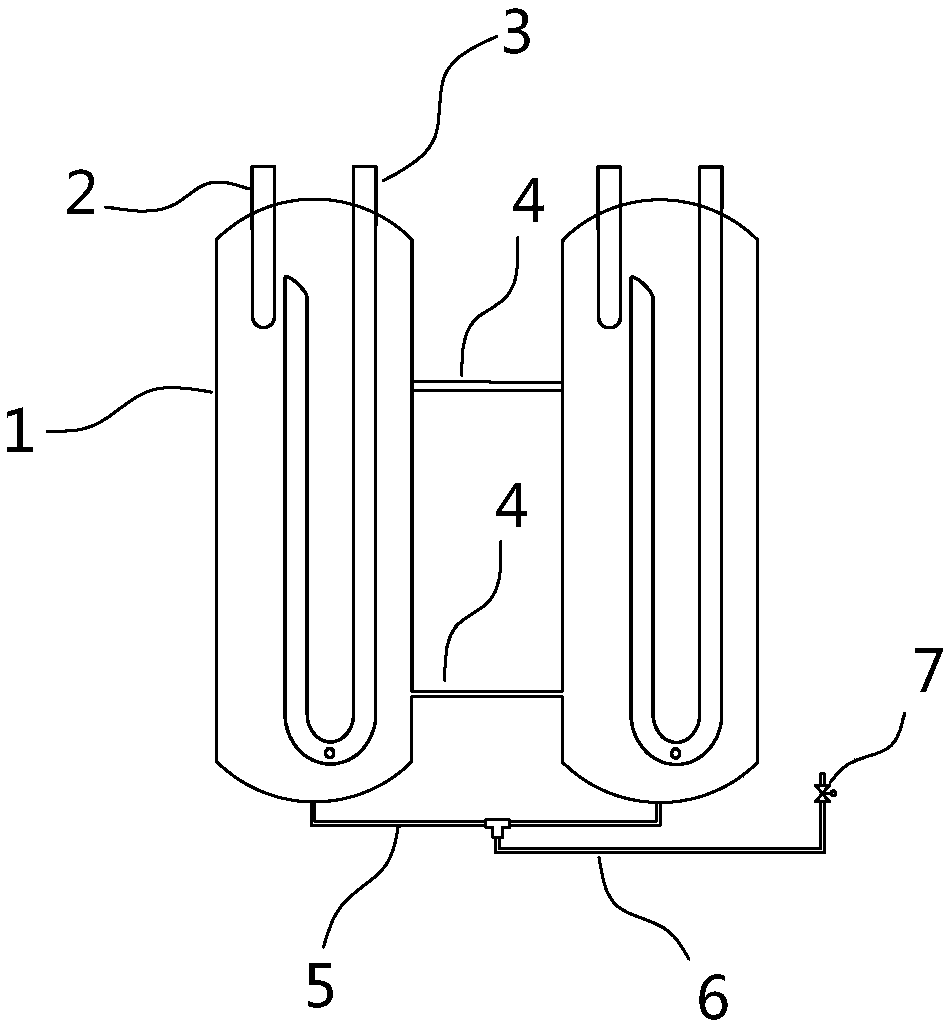

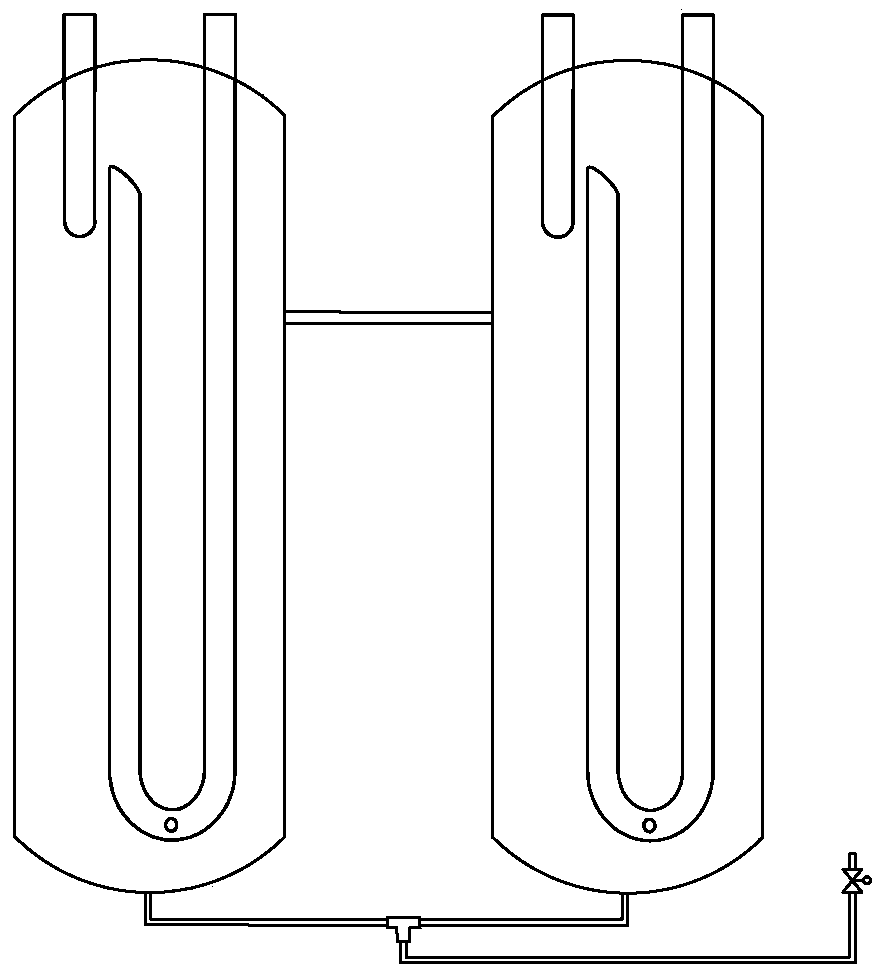

[0017] A combined gas-liquid separator structure includes two gas-liquid separators. The two gas-liquid separators have the same structure, including a cylinder body 1 , an inlet pipe 2 and an outlet pipe 3 . The inlet pipe 2 is a straight pipe extending from the top cover of the cylinder body 1 to the upper part of the cylinder body 1 from outside to inside. The outlet pipe 3 is a U-shaped pipe, its inlet end is located on the upper part of the cylinder body 1, and its outlet end protrudes from the top cover of the cylinder body 1, and is connected to the compressor. When the refrigerant containing gas and liquid enters the cylinder through the inlet pipe, it is stratified under the action of centrifugal force and gravity, and the liquid refrigerant sinks to the lower part of the gas-liquid separator, while the gas refrigerant is located The upper part of the cylinder flows out of the cylinder through the outlet pipe and returns to the compressor. The bottom of the outlet p...

Embodiment 2

[0021] This embodiment is basically the same as the first embodiment, the main difference is that there is one balance pipe in this embodiment, which is located at 1 / 2--5 / 6 of the height of the cylinder. At the same time, the diameter of the communication pipe in this embodiment is larger than that of the oil injection pipe, so that the communication pipe can allow the liquids in the two cylinders to communicate with each other, so that the liquid level between the cylinders is uniform, thus, a balance can be saved. tube, saves materials, simplifies the production process and reduces the cost.

[0022] The present invention maintains the liquid levels in a plurality of gas-liquid separators uniformly by arranging coil pipes, and fully satisfies the operation requirements of large-capacity units. At the same time, through the arrangement of the connecting pipe and the oil injection pipe, the refrigerant or lubricating oil can be added or discharged evenly during debugging or ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com