Multitubular slurry bed reactor and reaction system

A reaction system and reactor technology, applied in the chemical industry, can solve the problems of difficult temperature control, uneven mixing of gas-liquid-solid three-phase, short contact time of reaction raw materials, etc., achieve temperature stability, improve gas-liquid flow field distribution, reduce effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the present invention will be described in more detail below with reference to the drawings and examples, so as to better understand the solution of the present invention and its advantages in various aspects. However, the specific embodiments and examples described below are for the purpose of illustration only, rather than limiting the present invention.

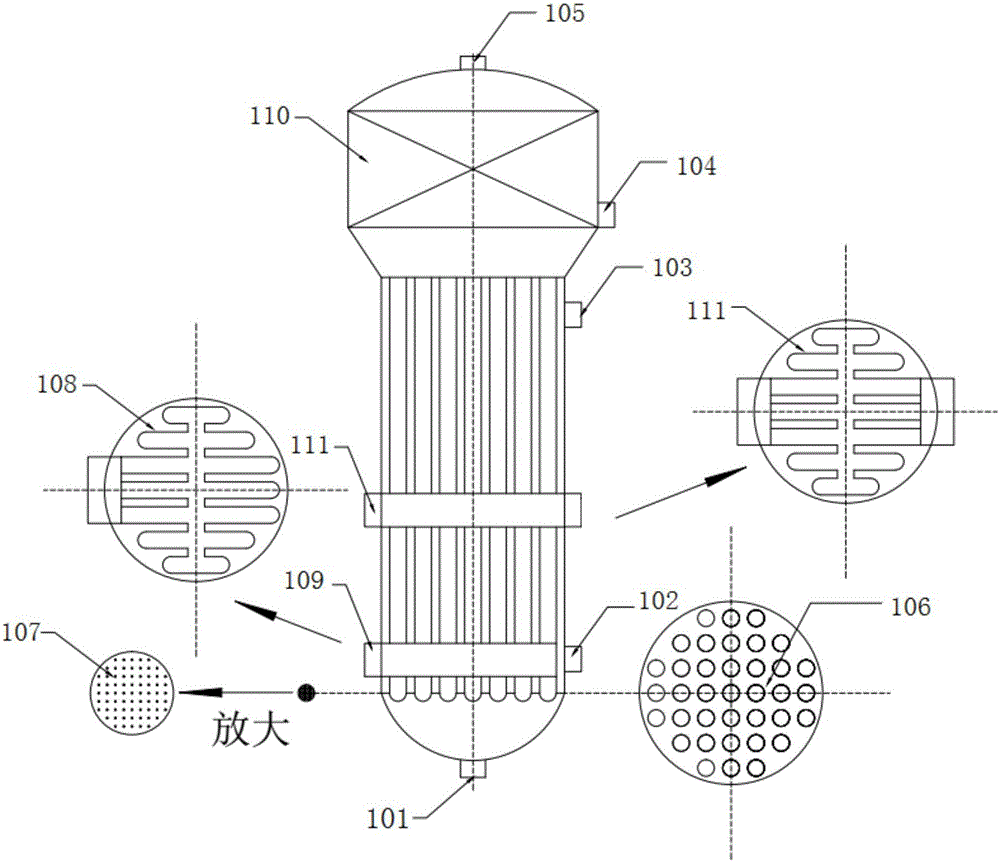

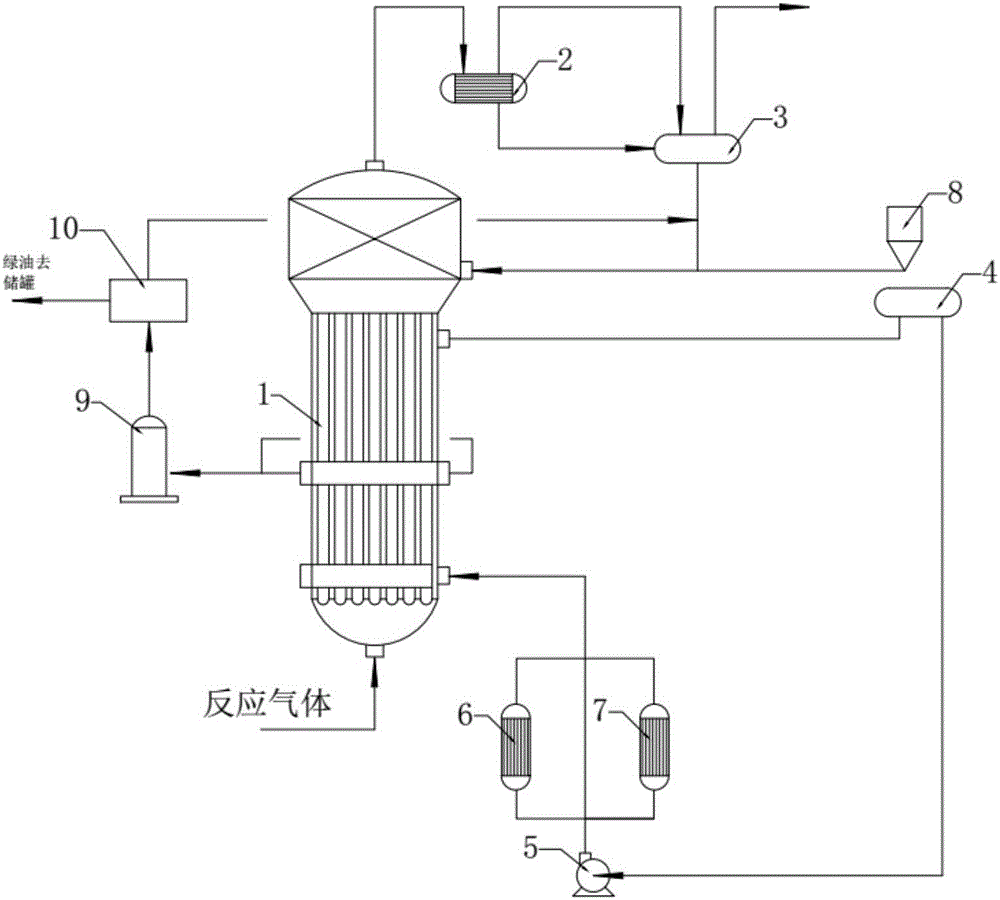

[0037] Such as figure 1 As shown, the tubular slurry bed reactor 1 of the present invention is a reactor for preparing ethylene from high-concentration acetylene. The tube-and-tube slurry-bed reactor 1 includes an inlet section, a tube-and-tube distribution section, and an expansion section arranged in sequence, as well as upper and lower tube-and-tube communication zones 111 and 108 that communicate with the tube-and-tube distribution section.

[0038] Such as figure 1 As shown, the gas inlet section is arranged at the bottom of the tubular slurry bed reactor 1, and the gas inlet secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com