A kind of anti-icing wind power generator blade and its preparation process

A wind turbine, anti-icing technology, applied in the direction of wind turbines, wind power generation, engines, etc., can solve the problems of anti-icing, damage to machines and personnel, and reduce use efficiency, etc., to extend outdoor use Long life, save manpower and material resources, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with specific embodiments.

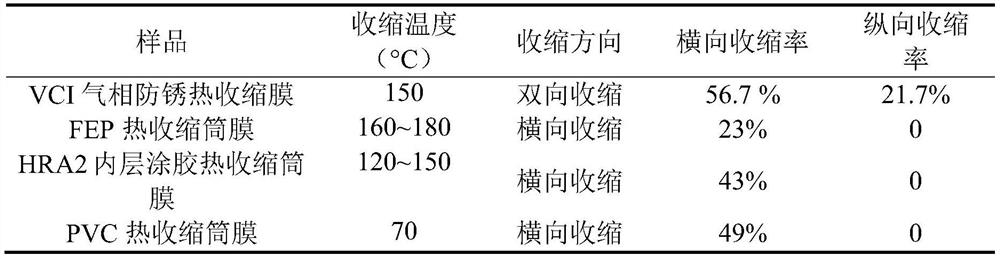

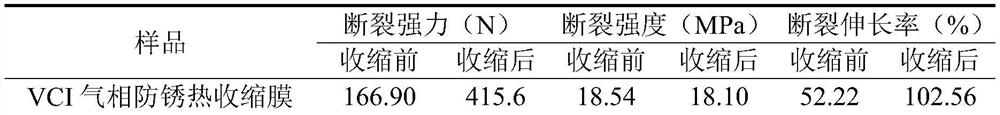

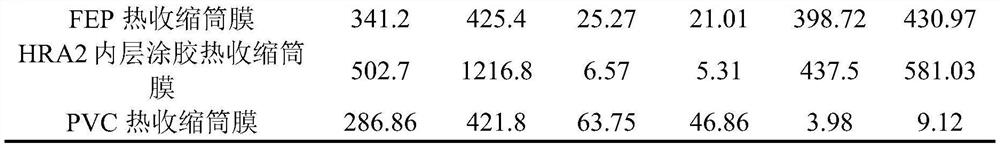

[0032] An anti-icing wind turbine blade, the surface of the PVC heat shrinkable film base material is treated with CF 4 After etching, it becomes a rough surface with multiple grooves and pits, and a PTFE coating is deposited on the rough surface. The grooves, pits and PTFE coating form a tight cross-linked network micro-nano surface structure, CF via ionic body 4 Etching the surface of the PVC heat-shrinkable film substrate provides a premise guarantee for improving the bonding fastness between the coating and the PVC heat-shrinkable film. In addition to roughening the surface of the film, CF4 plasma pretreatment introduces fluorine-containing groups, which provides the possibility for the deposition of fluorine-containing groups in the next step, and then improves the bonding fastness between the two, and strengthens the PTFE coating The combination with the substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com