High-end knitted fabric and processing method thereof

A technology for knitted fabrics and processing methods, applied in knitting, warp knitting, textiles and papermaking, etc., which can solve the problems of increasing fabric processing procedures and processing costs, troublesome washing and care, loss of fabric elasticity, etc., and achieve excellent flame retardancy and antibacterial Performance, improved flame retardant and antibacterial properties, and the effect of changing styles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A processing method for high-end knitted fabrics, the specific steps are:

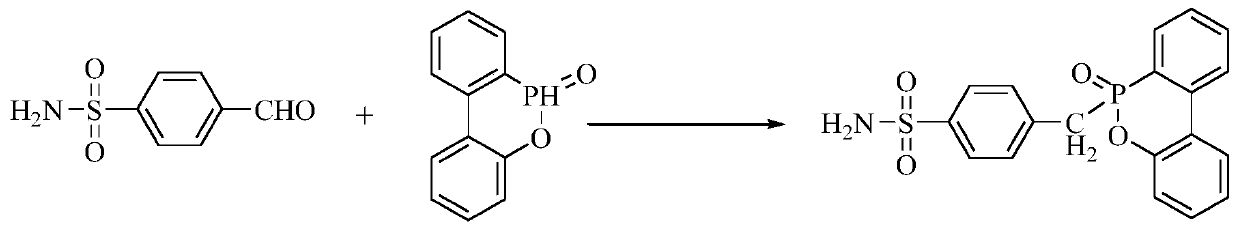

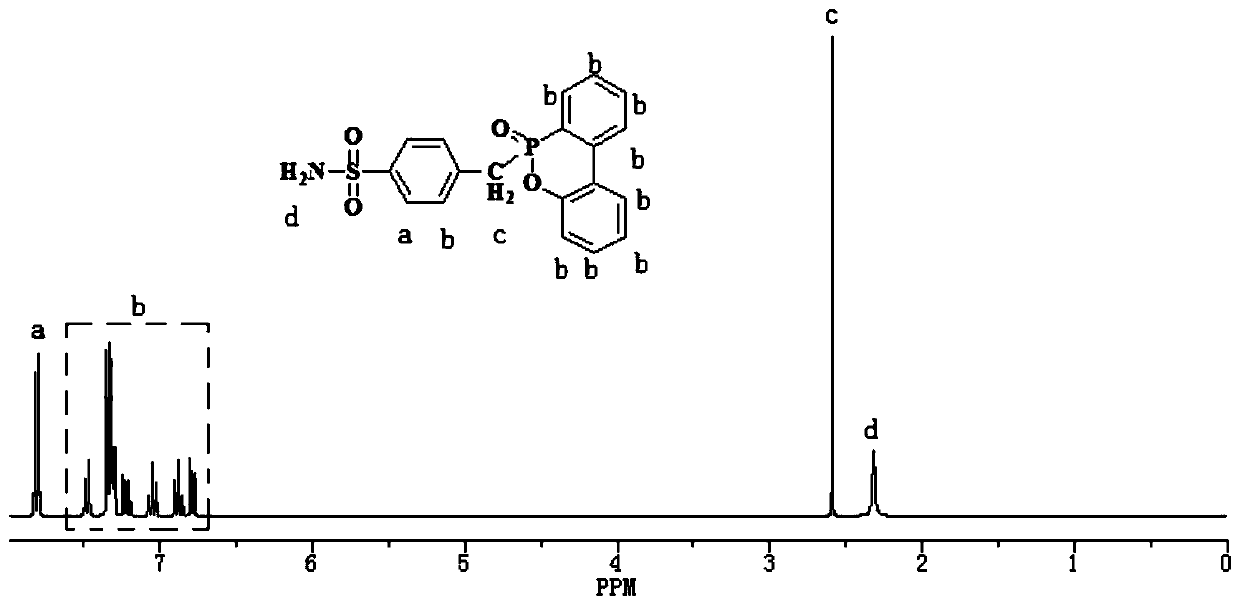

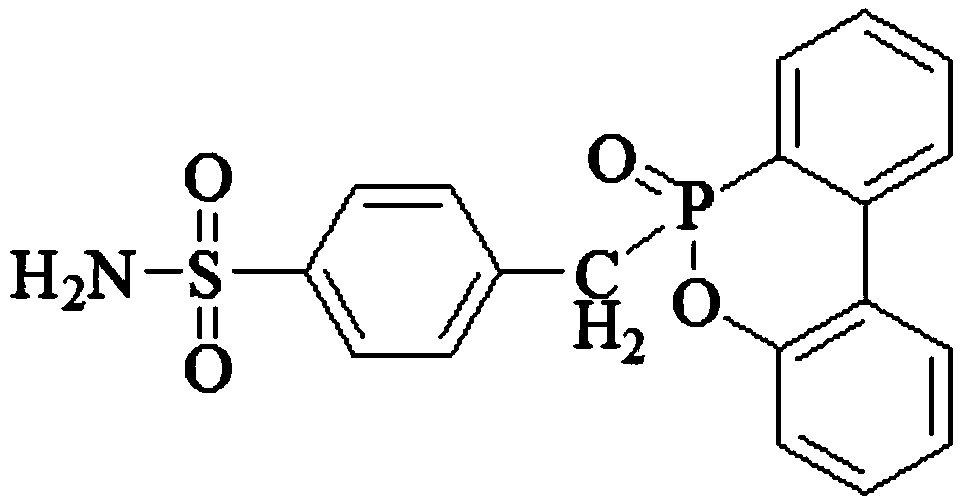

[0068] (1) Preparation of high-end modifiers

[0069] P-aldobenzenesulfonamide and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxa (DOPO) are used as raw materials, and a high-end modifier is obtained by chemical reaction. Its chemical structure is shown as follows:

[0070]

[0071] The specific process for the preparation of high-end modifiers is:

[0072] P-aldobenzenesulfonamide and 9,10-dihydro-9-oxa-10-phosphinephenanthrene-10-oxa (DOPO) are raw materials, using thionyl chloride as solvent, and then using thionyl chloride to convert p-aldehyde Mix and dissolve benzenesulfonamide and DOPO and add them into the reaction flask, then react at reflux at 65-75°C for 12-16 hours, then add dimethylacetamide, and then react at 200-210°C for high temperature reaction for 2~ 3h, finally get a light yellow viscous liquid, and then distill the solution under pressure at 180-190°C, and then dissol...

Embodiment 2

[0096] A processing method for high-end knitted fabrics, the specific steps are:

[0097] (1) Preparation of high-end modifiers

[0098] P-aldobenzenesulfonamide and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxa (DOPO) are used as raw materials, and a high-end modifier is obtained by chemical reaction. Its chemical structure is shown as follows:

[0099]

[0100] The specific process for the preparation of high-end modifiers is:

[0101]P-aldobenzenesulfonamide and 9,10-dihydro-9-oxa-10-phosphinephenanthrene-10-oxa (DOPO) are raw materials, using thionyl chloride as solvent, and then using thionyl chloride to convert p-aldehyde Mix and dissolve benzenesulfonamide and DOPO and add them into the reaction flask, then react at reflux at 65-75°C for 12-16 hours, then add dimethylacetamide, and then react at 200-210°C for high temperature reaction for 2~ 3h, finally get a light yellow viscous liquid, and then distill the solution under pressure at 180-190°C, and then dissolv...

Embodiment 3

[0124] A processing method for high-end knitted fabrics, the specific steps are:

[0125] (1) Preparation of high-end modifiers

[0126] P-aldobenzenesulfonamide and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxa (DOPO) are used as raw materials, and a high-end modifier is obtained by chemical reaction. Its chemical structure is shown as follows:

[0127]

[0128] The specific process for the preparation of high-end modifiers is:

[0129] P-aldobenzenesulfonamide and 9,10-dihydro-9-oxa-10-phosphinephenanthrene-10-oxa (DOPO) are raw materials, using thionyl chloride as solvent, and then using thionyl chloride to convert p-aldehyde Mix and dissolve benzenesulfonamide and DOPO and add them into the reaction flask, then react at reflux at 65-75°C for 12-16 hours, then add dimethylacetamide, and then react at 200-210°C for high temperature reaction for 2~ 3h, finally get a light yellow viscous liquid, and then distill the solution under pressure at 180-190°C, and then dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Bursting strength | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com