Organic profile control agent and preparation method thereof

A regulator and profile technology, which is applied in the field of acidified profile regulators, can solve the problems of insufficient strength, complex construction, poor pressure resistance, etc., and achieve the effects of large particle size range, shortened construction time, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] First take 60g rosin (C 19 h 29 COOH) and 15g glycerol (C 3 h 8 o 3 ), transported to the reaction kettle, heated to 260°C, and polymerized for 10 hours to obtain solid particles of the profile regulator; then take the solid particles of the profile regulator in 103.8g of aqueous solution, and then add 0.8g of dodecylbenzenesulfonate in sequence sodium nitrite, 0.4g ethylene glycol monobutyl ether, 20g tartaric acid, and stir evenly to obtain a profile regulator with a suspension particle size range of 30-60 μm.

Embodiment 2

[0033] First take 65g rosin (C 19 h 29 COOH) and 20g pentaerythritol (C 5 h 12 o 4 ), transported to the reaction kettle, heated to 260°C, and polymerized for 10 hours to obtain solid particles of the profile regulator; then take the solid particles of the profile regulator in 94g of aqueous solution, and then add 0.8g of dodecylbenzenesulfonic acid in turn Sodium, 0.2 g of ethylene glycol monobutyl ether, and 20 g of malic acid are stirred evenly to obtain a profile regulator with a suspension particle size range of 90 to 120 μm.

Embodiment 3

[0035] First take 80g rosin (C 19 h 29 COOH) and 20g trimethylolpropane (C 6 h 14 o 3 ), transported to the reaction kettle, heated to 260°C, and polymerized for 10 hours to obtain solid particles of the profile regulator; then take the solid particles of the profile regulator in 89.4g of aqueous solution, and then add 0.4g of dodecylbenzenesulfonate in sequence Na2SO4, 0.2 g of isopropanol, and 10 g of malic acid were stirred evenly to obtain a profile regulator with a suspension particle size range of 120 to 150 μm.

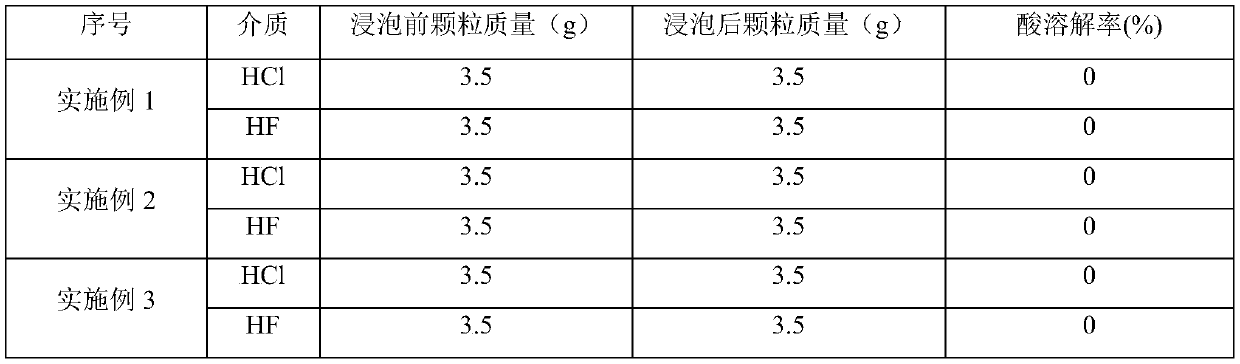

[0036] The solubility of Examples 1-3 in water, acid and oil was measured at normal temperature (25°C) and 80°C respectively.

[0037] Take 3.5g of the profile adjuster particles and soak them in HCl and HF respectively for 1 hour, measure the mass of the profile adjuster particles after soaking, and calculate the solubility of the particles in the two acid solutions by the weight loss method.

[0038] Take 3.5g of the profile regulator particles and soak ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com