Luminous prefabricated sports surface layer, luminous prefabricated sports paving material, and preparation method of paving material

A prefabricated, moving surface technology, applied in pavement, buildings, roads, etc., to achieve the effect of improving physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059]A preparation method of the above-mentioned luminous prefabricated sports pavement may include the following steps:

[0060] (1) Preparation of surface layer:

[0061] After mixing the synthetic rubber, kaolin and / or white carbon black, organic filler, mineral oil, anti-aging agent, luminous powder and toner in the surface layer, kneading and calendering to produce a tablet; the obtained sheet is Adding the vulcanizing agent, accelerator and foaming agent in the surface layer to the rubber material, kneading, calendering and extruding the sheet to obtain the surface layer;

[0062] (2) Preparation of bottom layer:

[0063] After mixing the synthetic rubber, calcium carbonate, organic filler and mineral oil in the bottom layer, knead and roll out the sheet; add the vulcanizing agent in the bottom layer to the obtained sheet rubber to accelerate agent, foaming agent, kneading, calendering and tableting to obtain the bottom layer;

[0064] (3) Compounding and vulcanizati...

Embodiment 1-7

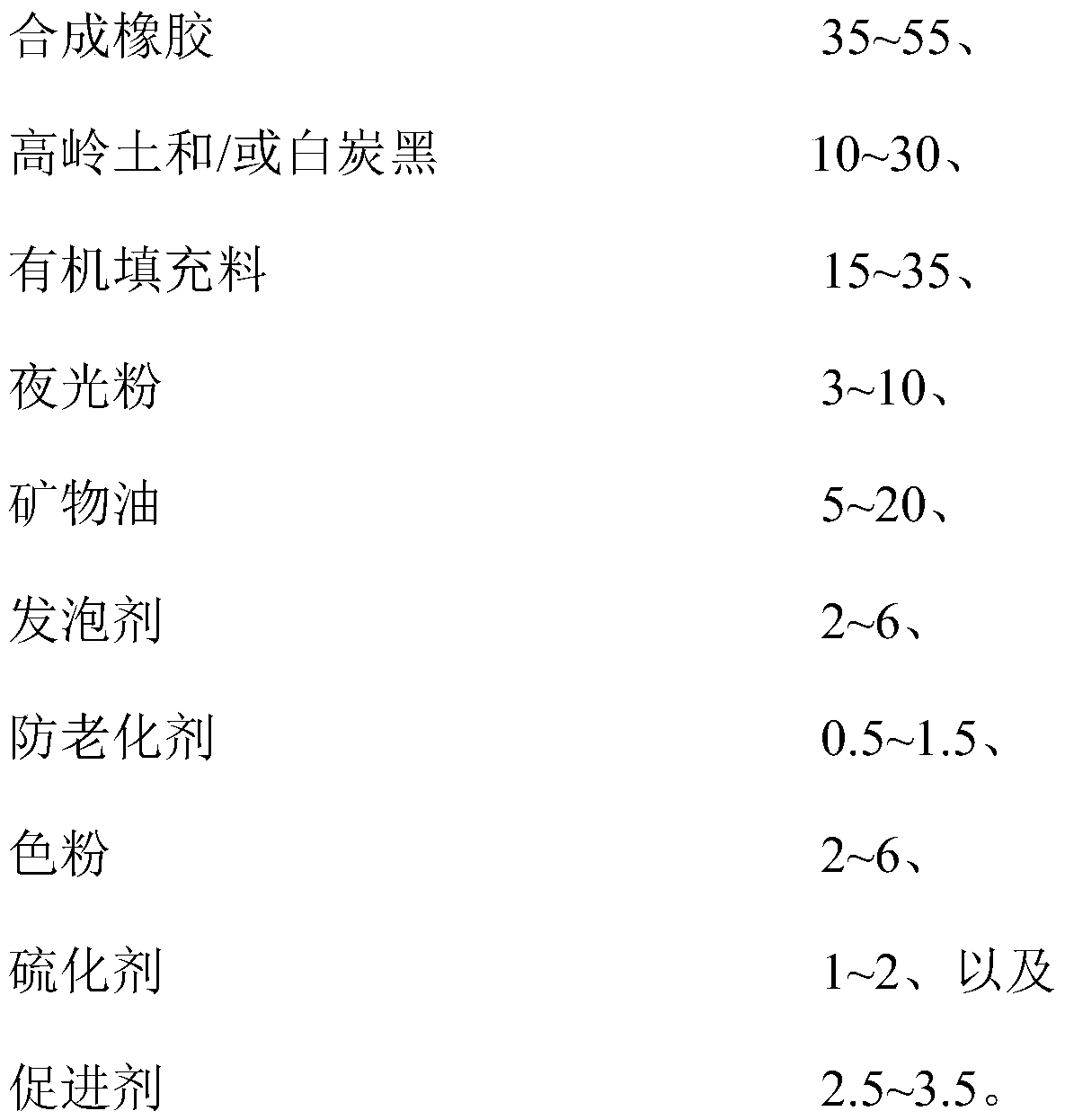

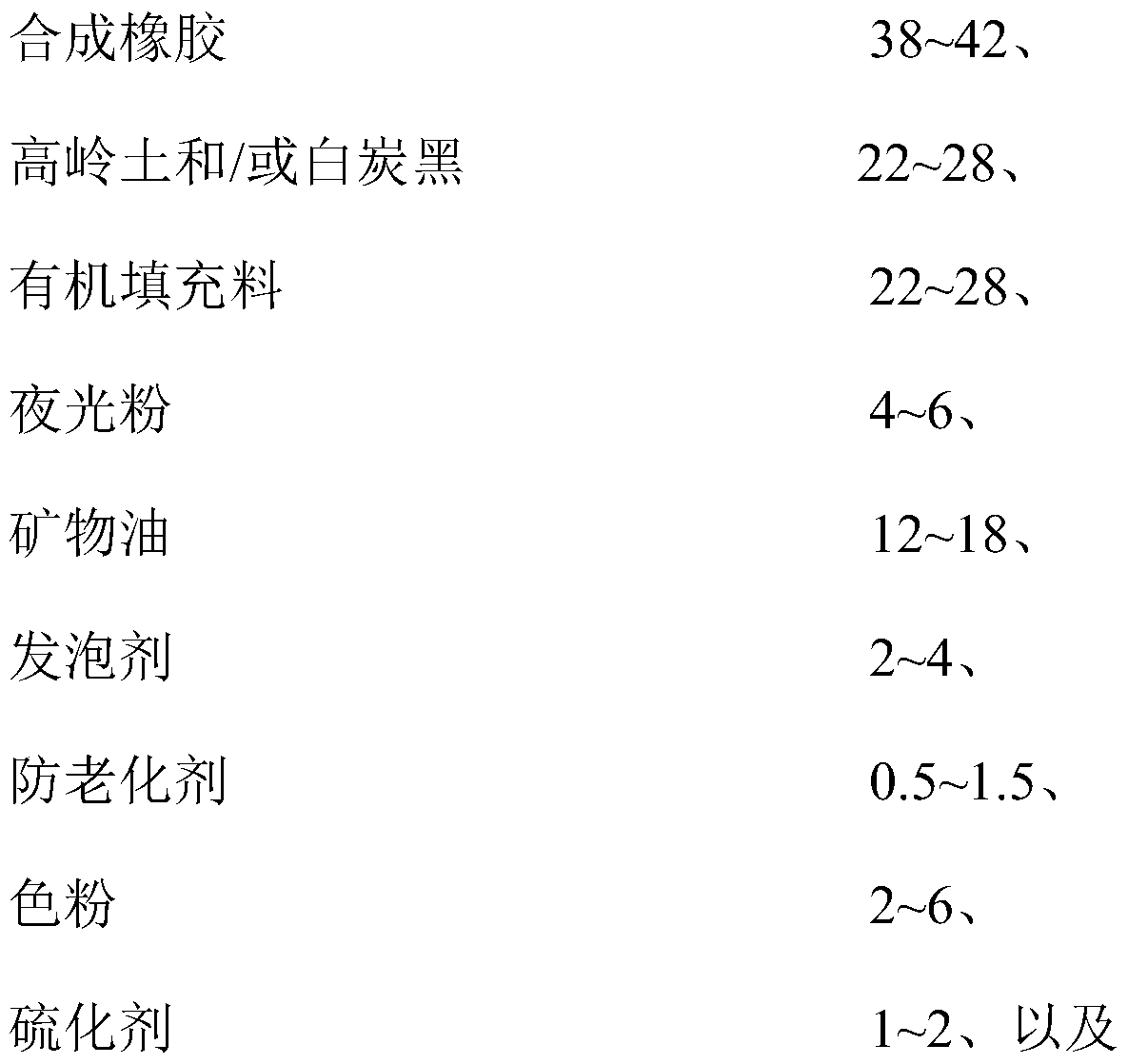

[0073] Embodiment 1-7 provides 7 kinds of luminous prefabricated sports paving materials, and its formula is prepared according to the weight part of Table 1:

[0074] Table 1

[0075]

[0076]

[0077] The preparation method of the above-mentioned luminous prefabricated sports pavement is as follows:

[0078] (1) Preparation of surface film:

[0079] Mix the unvulcanized rubber, inorganic filler, organic filler, mineral oil, anti-aging agent, photo-energy storage luminous powder, and toner in the surface layer raw materials by weight, put them into a rubber mixer, and knead for 15 minutes to obtain surface layer compound;

[0080] Put the surface layer mixed rubber into the open mill and calender the sheet to obtain the surface layer sheet rubber, and then cool it to below 60°C;

[0081] Put the vulcanizing agent, accelerator, foaming agent and surface layer sheet rubber in the surface layer raw materials into a rubber mixer, knead for 3 minutes, and then use calende...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com