Method and system apparatus for treating high-salt volatile organic wastewater

A volatile organic and organic wastewater technology, applied in water/sewage treatment, chemical instruments and methods, heating water/sewage treatment, etc., can solve problems such as excessive organic residues and affect the degradation of organic matter, shorten the process flow, and ensure water quality. , the effect of shortening the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

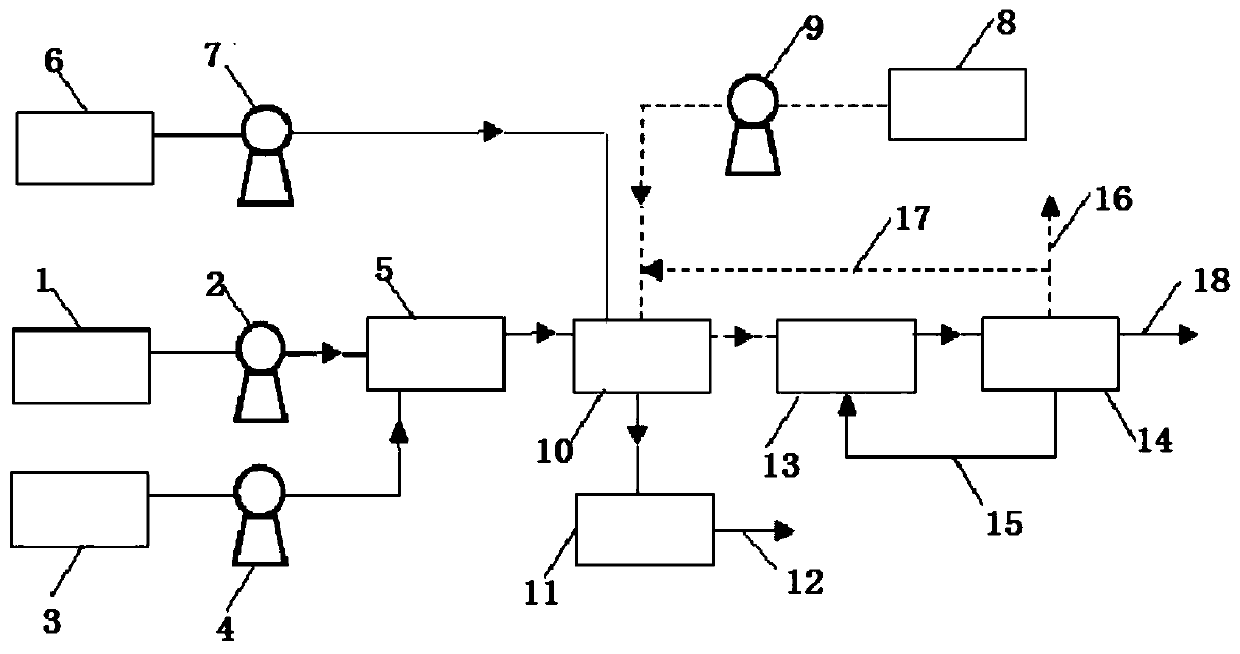

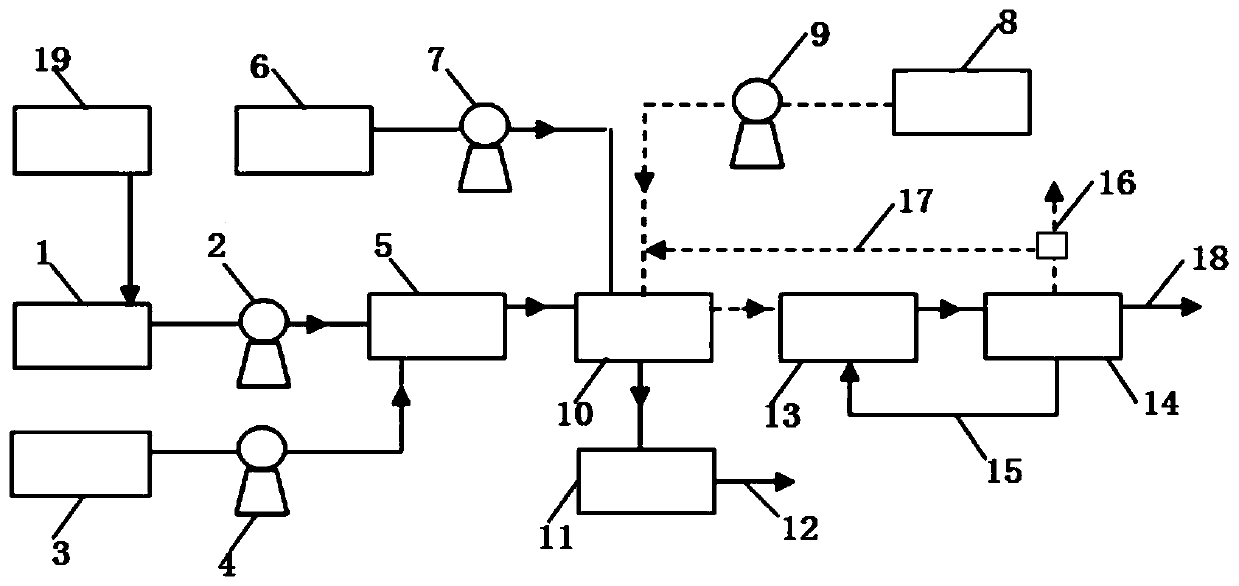

Image

Examples

Embodiment 1

[0041] A gas-liquid two-phase synchronous oxidation method for treating high-salt volatile organic wastewater, the steps are as follows:

[0042] (1) Obtain the pretreated organic wastewater, and the SS (suspended solids) in the wastewater is lower than 10mg / L;

[0043] (2) Pump organic waste water, acid conditioner and alkali conditioner into the pipeline mixer, control the initial pH of waste water to be 4, in order to improve the formation of sulfuric acid free radicals and reduce the formation of carbonate scaling;

[0044] (3) Transfer the mixed liquid in the pipeline mixer to the evaporation reactor, control the evaporation temperature to 60°C, use the evaporation heat to activate persulfate to speed up the reaction rate, and at the same time reduce the possibility of equipment fouling and the overflow of volatile organic compounds ;

[0045] (4) According to the COD Cr with S 2 o 8 2- Pump the persulfate with a mass fraction of 4.5% into the evaporation reactor wit...

Embodiment 2

[0049] A gas-liquid two-phase synchronous oxidation method for treating high-salt volatile organic wastewater, the steps are as follows:

[0050] (1) Pretreatment of high-salt volatile organic wastewater, so that the SS (suspended solids) in the wastewater is lower than 10mg / L; the pretreatment method can be treated by membrane, coagulation, or filtration . Membrane treatment, coagulation or filtration methods are conventional wastewater pretreatment methods.

[0051] (2) pump organic waste water, acid conditioner and alkali conditioner into pipeline mixer, and control the initial pH of waste water to be 4.5;

[0052] (3) According to the COD Cr with S 2 o 8 2- Mass concentration ratio is that the ratio of 4.5 is the persulfate that the persulfate radical massfraction is pumped into evaporation reactor;

[0053] (4) Transport the mixed liquid in the pipeline mixer to the evaporation reactor, and control the evaporation temperature to be 65°C;

[0054] (5) Mix and react ...

Embodiment 3

[0057] A gas-liquid two-phase synchronous oxidation method for treating high-salt volatile organic wastewater, the steps are as follows:

[0058] (1) Pretreat high-salt volatile organic wastewater so that the SS (suspended solids) in the wastewater is lower than 10mg / L;

[0059] The pretreatment method can be treated by membrane, coagulation, or filtration, which makes the treatment method a conventional wastewater pretreatment method.

[0060] (2) pump organic waste water, acid conditioner and alkali conditioner into pipeline mixer, and control the initial pH of waste water to be 5;

[0061] (3) Transport the mixed liquid in the pipeline mixer to the evaporation reactor, and control the evaporation temperature to 70°C;

[0062] (4) At the same time follow the COD Cr with S 2 o 8 2- A mass concentration ratio of 4 to 5 is used to pump persulfate with a mass fraction of persulfate radicals of 5.5% into the evaporation reactor;

[0063] (5) Mix and react the evaporated ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com