Method for catalytic preparation of high-purity black phosphorus by adopting fixed bed

A catalytic preparation and fixed bed technology, applied in the preparation of phosphorus, etc., can solve the problems of difficult industrial continuous production, poor crystallinity of black phosphorus, high production cost of black phosphorus, and achieve low loss, less impurities and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing high-purity black phosphorus by fixed-bed catalysis, specifically comprising the following steps:

[0025] (1) Preparation of solid-state catalyst phosphorus-selenium-tin ternary compound: according to the molar ratio of phosphorus to selenium is 2, and the molar ratio of tin to selenium is 15, weigh and mix, and calcinate at 550°C for 22h in an argon atmosphere. Then drop to room temperature, repeat the above heating and cooling process for calcination once;

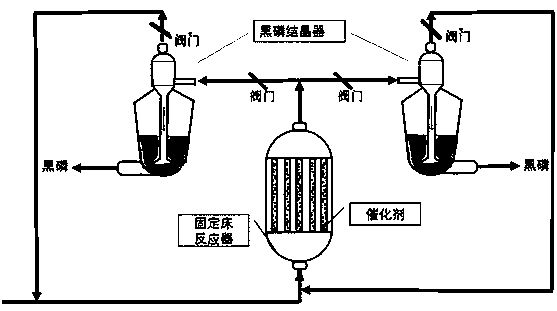

[0026] (2) if figure 1 As shown, the solid-state catalyst phosphorus-selenium-tin ternary compound prepared in step (1) is installed in a fixed-bed reactor, and gaseous red phosphorus is slowly introduced into the fixed-bed reactor through an air duct to control the fixed-bed reaction The temperature inside the vessel is 550°C, and the catalytic reaction takes 30 minutes. Under the catalysis of the solid catalyst, the gaseous phosphorus molecules are converted into gaseous black phosphorus...

Embodiment 2

[0030] A method for preparing high-purity black phosphorus by fixed-bed catalysis, specifically comprising the following steps:

[0031] (1) Preparation of solid-state catalyst phosphorus-selenium-gallium ternary compound: according to the molar ratio of phosphorus to selenium of 2.4, and the molar ratio of gallium to selenium of 13, weigh and mix, and calcinate at 500°C for 20h in an argon atmosphere. Then drop to room temperature, repeat the above heating and cooling process for calcination 2 times;

[0032] (2) Install the solid-state catalyst phosphorus-selenium-gallium ternary compound prepared in step (1) in a fixed-bed reactor, and slowly pass gaseous yellow phosphorus into the fixed-bed reactor through an air duct to control the fixed-bed reaction The temperature inside the vessel is 450°C, and the catalytic reaction takes 25 minutes. Under the catalysis of the solid catalyst, the gaseous phosphorus molecules are converted into gaseous black phosphorus molecules;

[0...

Embodiment 3

[0036] A method for preparing high-purity black phosphorus by fixed-bed catalysis, specifically comprising the following steps:

[0037] (1) Preparation of solid-state catalyst phosphorus-iodine-bismuth ternary compound: according to the molar ratio of phosphorus to iodine is 2.6, and the molar ratio of bismuth to iodine is 11, weigh and mix, and calcinate at 450°C for 18h in an argon atmosphere. Then be down to room temperature, repeat above heating and cooling process calcining 3 times;

[0038] (2) Install the solid-state catalyst phosphorus-iodine-bismuth ternary compound prepared in step (1) in a fixed-bed reactor, and slowly pass gaseous red phosphorus into the fixed-bed reactor through an air duct to control the fixed-bed reaction The temperature inside the vessel is 400°C, and the catalytic reaction takes 20 minutes. Under the catalysis of the solid catalyst, the gaseous phosphorus molecules are converted into gaseous black phosphorus molecules;

[0039] (3) Open the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com