High iron bauxite flotation silicon removal-deep reduction smelting method

A high-iron bauxite and flotation technology, which is applied in flotation, process efficiency improvement, solid separation, etc., can solve the problems of increasing the amount of solid waste red mud and reducing the production capacity of a single machine, so as to save energy and improve the quality of molten iron Quality, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

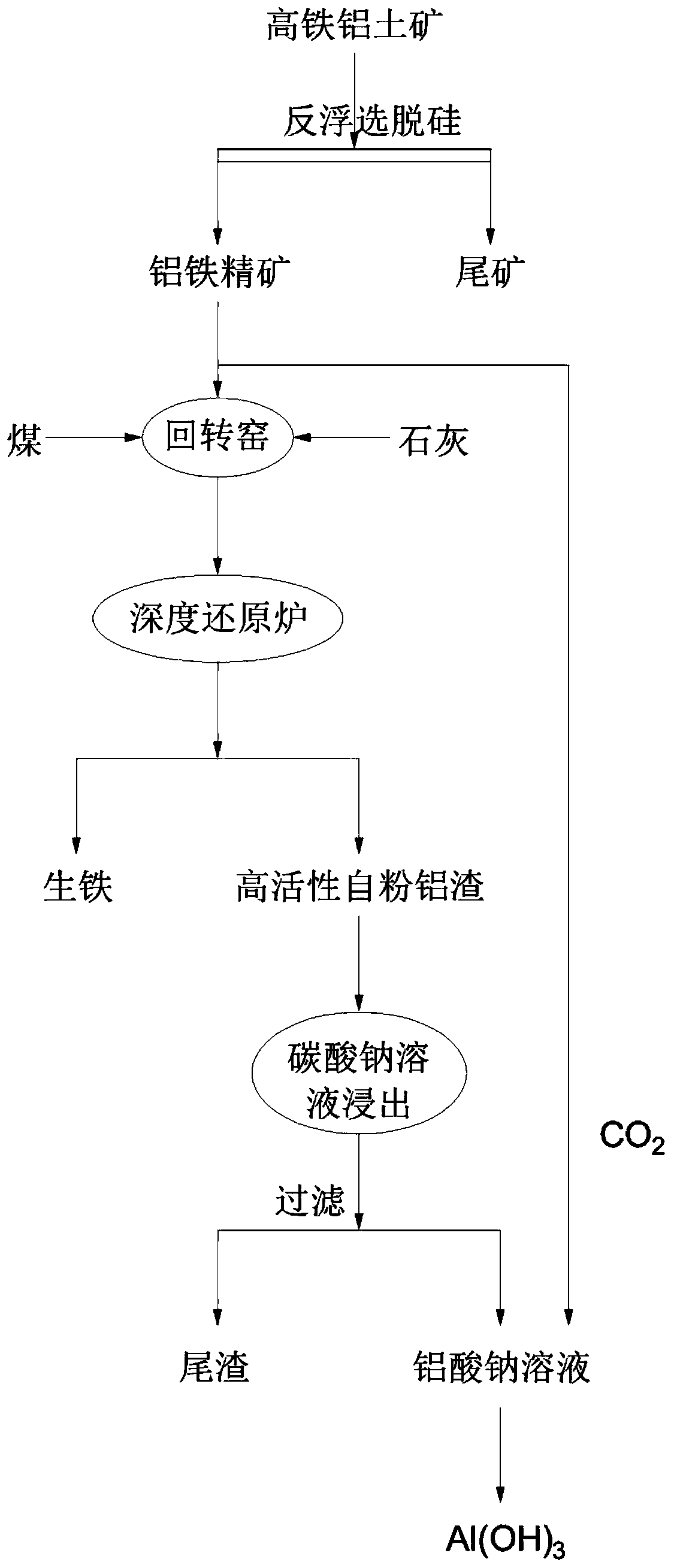

[0031] A certain high-iron bauxite that present embodiment adopts contains TFe 26.84% by weight percentage, Al 2 o 3 36.28%, SiO 2 10.06%, it is subjected to flotation desiliconization-deep reduction smelting, such as figure 1 shown, follow the steps below:

[0032] (1) First, crush the high-iron bauxite, grind the ore until the particle size of -0.074mm accounts for 70% of the mass, and use cationic reverse flotation technology, first coarse, second fine, and second sweep process, and perform pre-desilication treatment, of which Dodecylamine was used as collector, sodium hexametaphosphate was used as inhibitor, sulfuric acid was used to adjust the pH, and the pH was 5.5; 2 The quality score is 3%;

[0033] (2) The aluminum-iron concentrate after pre-desiliconization is mixed with a certain proportion of coal powder and lime, then added to the rotary kiln, and reduced and roasted at 1150°C to reduce part of the iron oxides to metallic iron; the amount of lime added is n(...

Embodiment 2

[0038] In this embodiment, a certain high-iron red mud containing TFe 28.57% by weight percentage, Al 2 o 3 35.48%, SiO 2 11.06%, pre-desilication-deep reduction smelting method is the same as embodiment 1, the difference is:

[0039] (1) SiO in concentrate after pre-desiliconization 2 The mass fraction is 4.04%;

[0040] (2) The reduction roasting temperature of the pre-desiliconized ore concentrate rotary kiln is 1050°C, and the amount of lime added is n(CaO) / n(Al 2 o 3 )=1.79; the amount of pulverized coal added is that the carbon ratio is 0.9; the metallization rate of iron after reducing and roasting the pre-desiliconized ore concentrate is 78%;

[0041] (3) The reduction temperature of the deep reduction furnace is 1450°C; the molten iron contains Fe 93.03%, C 3.52%, P 0.04%, S 0.01%, Si 0.33% by mass percentage;

[0042] (4) The concentration of sodium carbonate solution used for leaching is 100g / L, the leaching temperature is 85°C, the leaching time is 90 minutes,...

Embodiment 3

[0045] This embodiment adopts a certain high-iron bauxite containing TFe 27.85% by weight percentage, Al 2 o 3 36.27%, SiO 2 10.57%, method is the same as embodiment 1, and difference is:

[0046] (1) SiO in concentrate after pre-desiliconization 2 The mass fraction is 3.45%;

[0047] (2) The reduction roasting temperature of the pre-desiliconized ore concentrate rotary kiln is 1200°C, and the amount of lime added is n(CaO) / n(Al 2 o 3 )=1.80; the amount of pulverized coal added is that the carbon ratio is 1; the metallization rate of iron after reduction and roasting of the pre-desiliconized ore concentrate is 76%;

[0048] (3) The reduction temperature of the deep reduction furnace is 1420°C; the molten iron contains 92.67% Fe, 3.80% C, 0.03% P, 0.02% S, and 0.35% Si by mass percentage;

[0049] (4) The concentration of sodium carbonate solution used for leaching is 105g / L, the leaching temperature is 95°C, the leaching time is 88 minutes, the liquid-solid ratio is 8:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com