A method for comprehensive utilization of surrounding rock containing magnetite

A technology of magnetite and surrounding rock, which is applied in the field of beneficiation and comprehensive utilization of low-grade magnetite-containing surrounding rock, and can solve the unsatisfactory separation effect of bulk dry magnetic separator and the low recovery rate of magnetite , waste of iron ore resources and other issues, to alleviate the insufficient supply of iron ore resources, prevent over-grinding, and reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

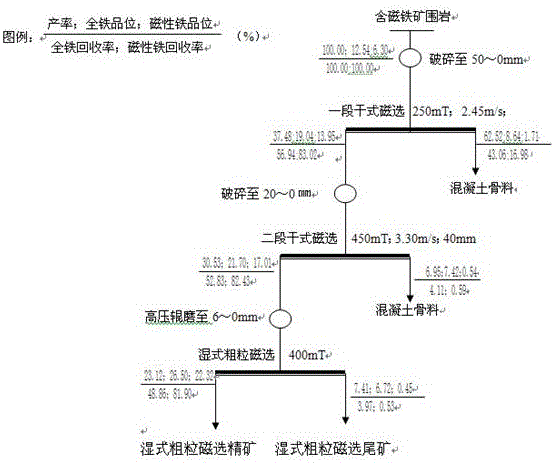

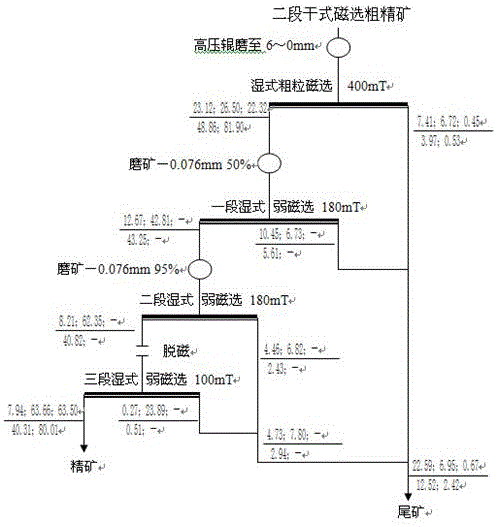

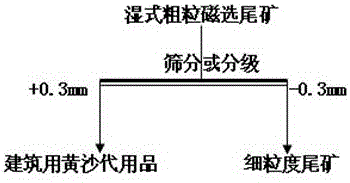

[0027] In order to describe the present invention, a method for comprehensive utilization of magnetite-containing surrounding rock according to the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0028] The object of treatment in this embodiment is the magnetite-containing surrounding rock stockpiled in the dump site of the Nanshan mining area of Masteel Group. The multi-element analysis and iron phase analysis of the magnetite-containing surrounding rock were carried out, and the results are shown in Table 1 and Table 2.

[0029] Table 1 Chemical multi-element analysis results of magnetite-bearing surrounding rocks (%)

[0030]

[0031] Table 2 Analytical results of iron phases in surrounding rocks containing magnetite (%)

[0032]

[0033] The analysis shows that the iron content of the surrounding rock containing magnetite is very low, with a total iron grade of 12.37% and a magnetic iron gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com