An amino atmosphere roller furnace production system

A production system and atmosphere roller technology, which is applied in the field of amino atmosphere roller furnace production system, can solve the problems of long length of the production system, and achieve the effects of low cost, simple operation, and reduced length and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

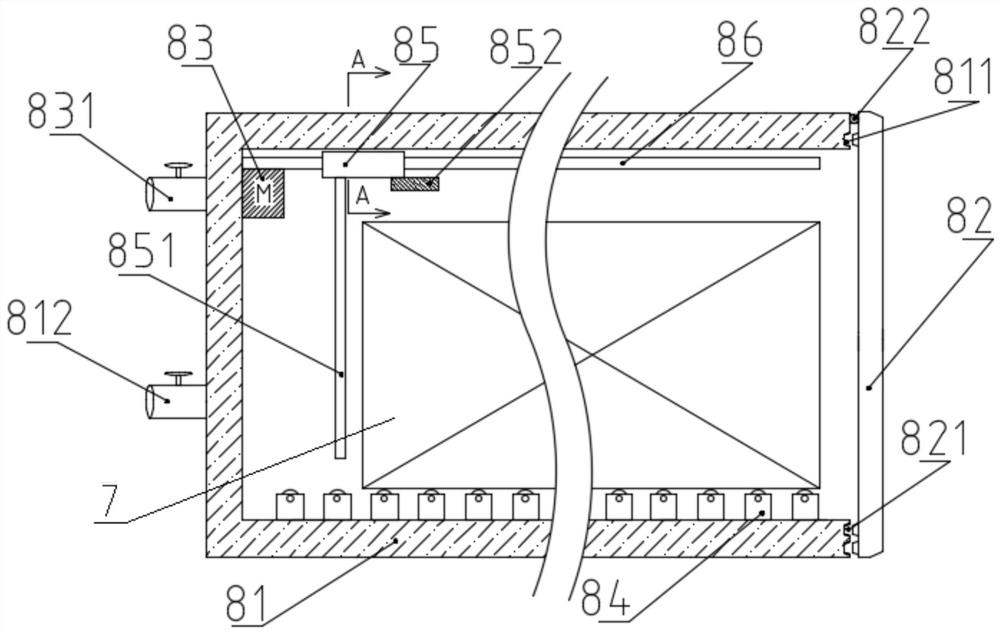

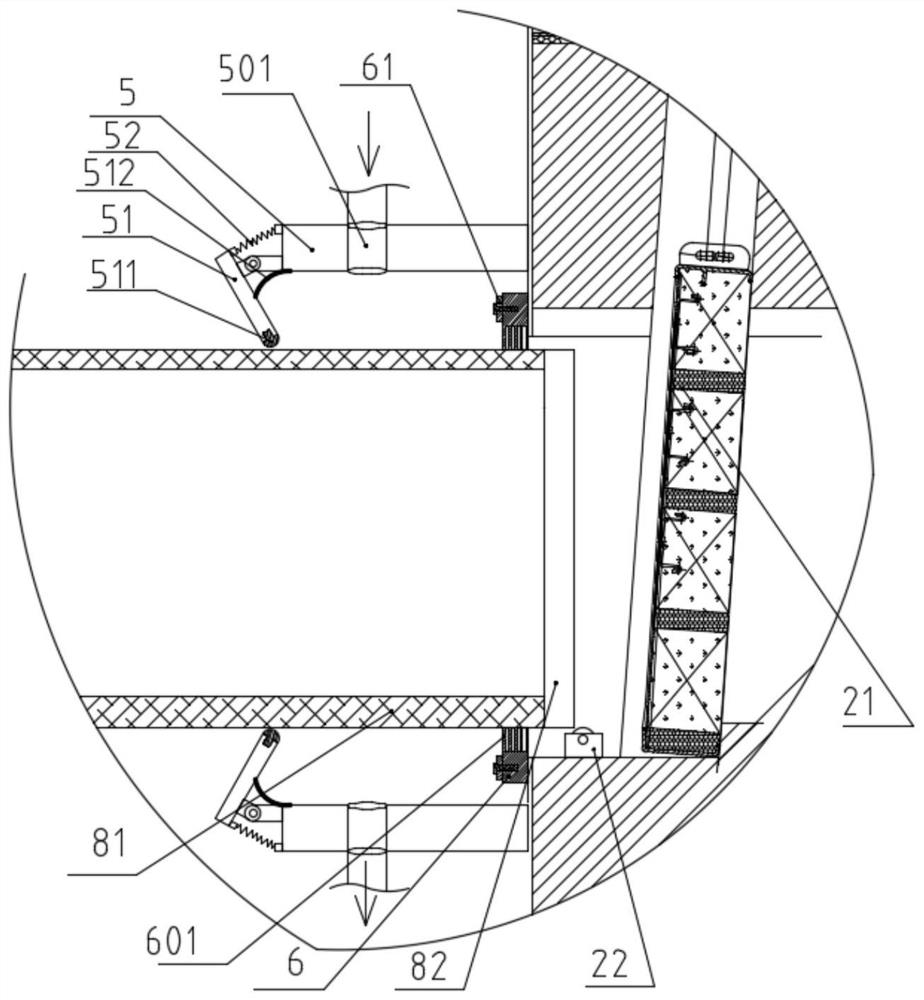

[0031] Such as Figure 1 to Figure 4 As shown: this embodiment discloses an amino atmosphere roller furnace production system: a sealed feeding box 8, a feeding device and a charging platform 1 connected in sequence through the feeding device, a heating chamber 2, and a multi-component co-infiltration chamber 3 , the cooling chamber 4, and the discharge platform 7. The conveying device of this embodiment can adopt any one in the prior art, such as a crawler-type conveying device and a chain plate-type conveying device, which are not limited in this embodiment.

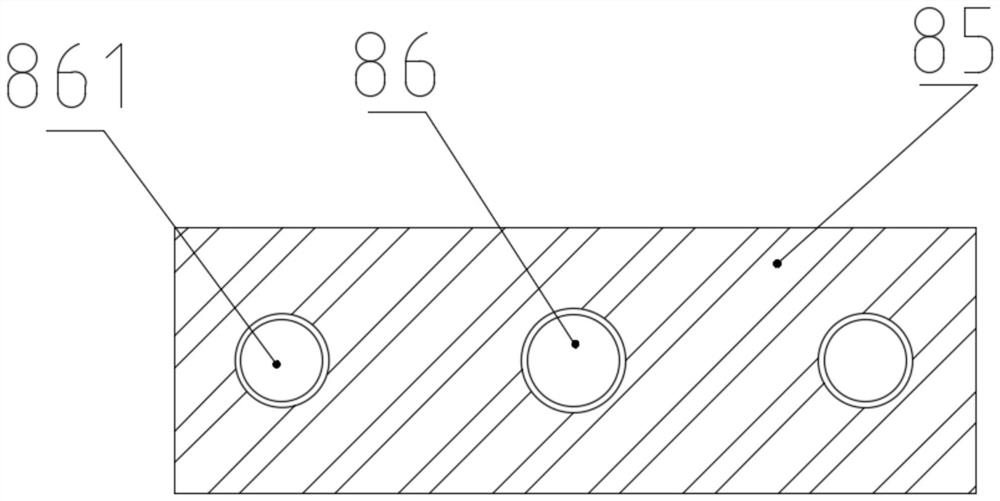

[0032] Such as figure 2 As shown: the sealed delivery box 8 is a hollow cuboid as a whole, and the sealed delivery box 8 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com