A method of using biomass coke to reduce emission and combustion of particulate matter

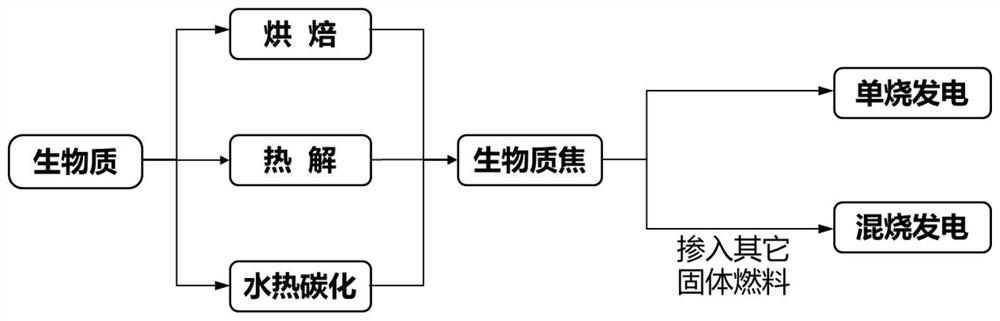

A technology for biomass coke and particulate matter, which is used in biofuels, waste fuels, fuels, etc., can solve problems such as human health hazards and particulate matter environmental pollution, and achieve the effects of increased burnout, high energy density, and strong grindability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

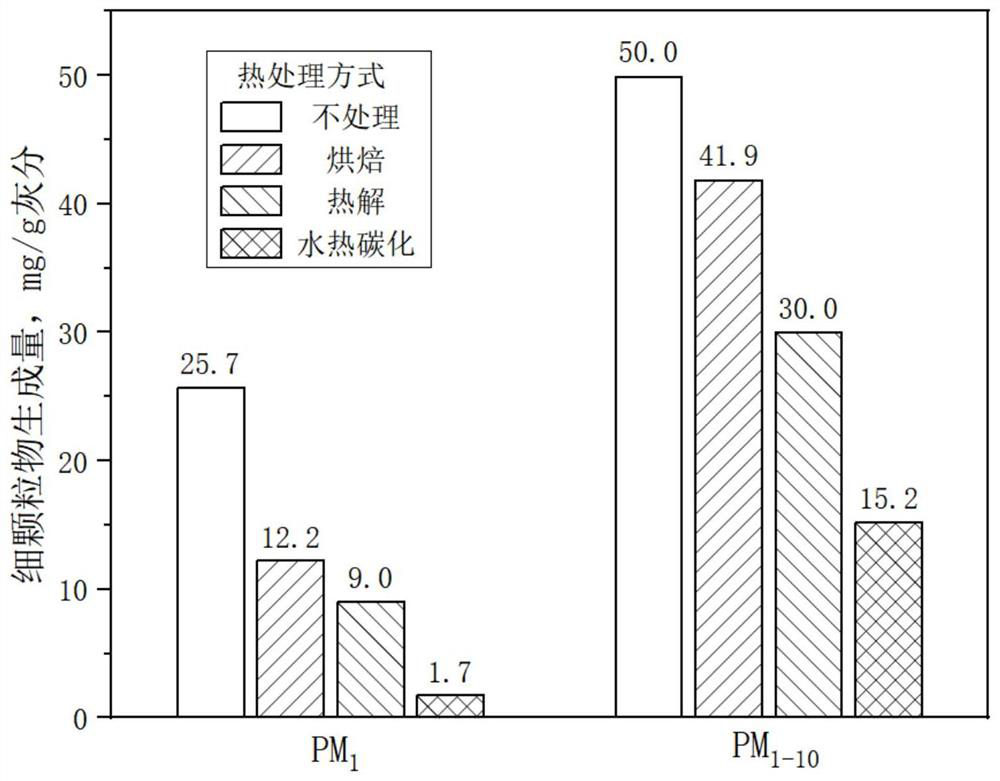

[0031] Example 1: Detection of particulate matter emission reduction effect of single-burning biomass coke

[0032] In this example, rice straw was selected as the raw material, and biomass coke was prepared by roasting, pyrolysis, and hydrothermal carbonization, and the mechanism of the emission reduction effect of biomass coke was verified based on the emission of particulate matter based on ash content.

[0033] First crush the straw to a particle size of less than 420μm, then fully mix 30g of straw with 300ml of deionized water in a 500ml stainless steel cylinder, and then use 300ml / min of N 2 Purging air for 10 minutes, the target temperature is 240°C, and the heating rate is 4-5K / min. After constant temperature for half an hour, quickly cool to room temperature in an ice bath, then filter and dry to obtain hydrothermal carbonized coke; Put 10g of straw into the sample tray and send it into the 2 In the furnace, the carrier gas flow rate is 3L / min, the temperature is rai...

Embodiment 2

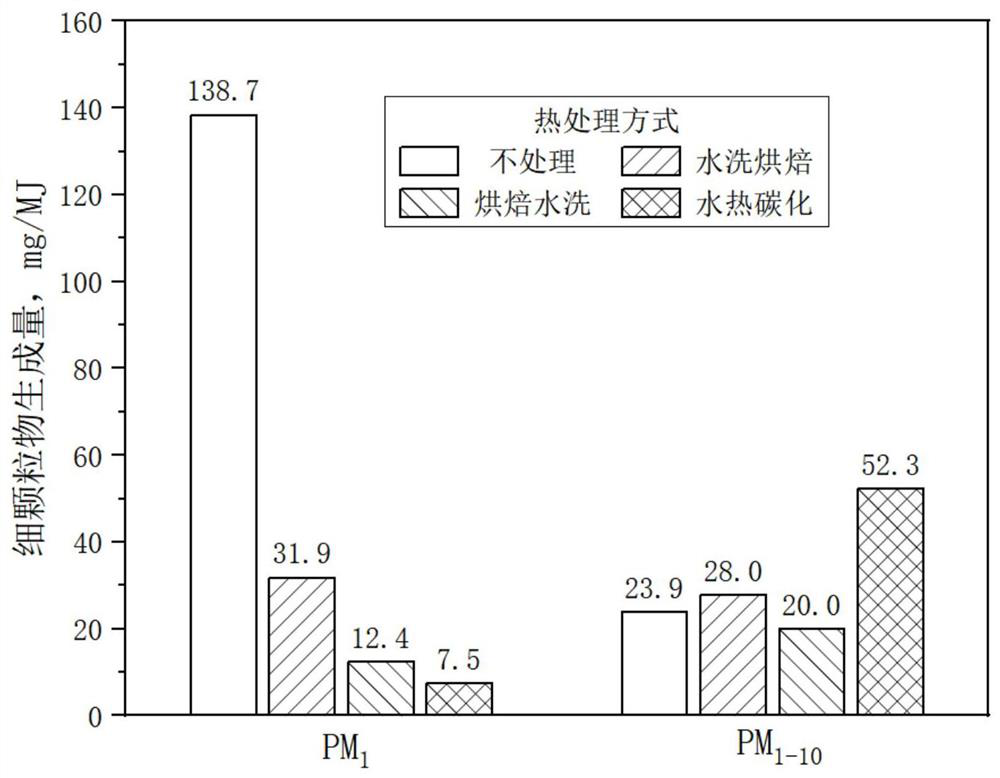

[0036] Example 2: Detection of particulate matter emission reduction effect of biomass coke in single burning process with water washing process

[0037] In this example, another kind of rice straw was selected as the raw material, and biomass coke was prepared by three methods of washing first and then baking, first roasting and then washing, and hydrothermal carbonization, and the particle emission reduction effect of biomass char was tested.

[0038] Water washing is to mix biomass and water at a ratio of 1:10, and then stir at 400rpm for 2 hours. The method of hydrothermal carbonization and baking is the same as that of Example 1. Through these steps, washed baked coke, baked washed coke and hydrothermal carbonized coke are produced.

[0039] The method of single-burning biomass and detecting particulate matter is the same as that of Example 1.

[0040] Experimental results such as image 3 shown. The results show that, under the experimental conditions, the particulat...

Embodiment 3

[0041] Example 3: Detection of particulate matter emission reduction effect of co-firing biomass coke

[0042] In this example, rice straw was still selected as the raw material, and biomass coke was prepared by roasting, pyrolysis, and hydrothermal carbonization, and the particulate matter emission reduction effect of co-firing biomass coke and coal was tested.

[0043] The way of making coke is the same as that of Example 1.

[0044] Biomass coke and PDS coal were mixed according to the mass ratio of 1:1, and another two groups of comparison conditions of single-burning biomass coke and single-burning PDS coal were set up. The methods of burning and detecting particulate matter were the same as in Example 1.

[0045] The theoretical value calculated by the linear superposition of the experimental value of the co-firing process and the experimental value obtained by the single combustion of the two fuels is as follows: Figure 4 shown. The results show that, under the exper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com