Preparation method for floor ground insulation and leveling integrated self-leveling mortar

A self-leveling mortar and floor technology, applied in the field of building materials, can solve the problem of less floor insulation, and achieve the effects of good thermal insulation, short maintenance time, and high-quality comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

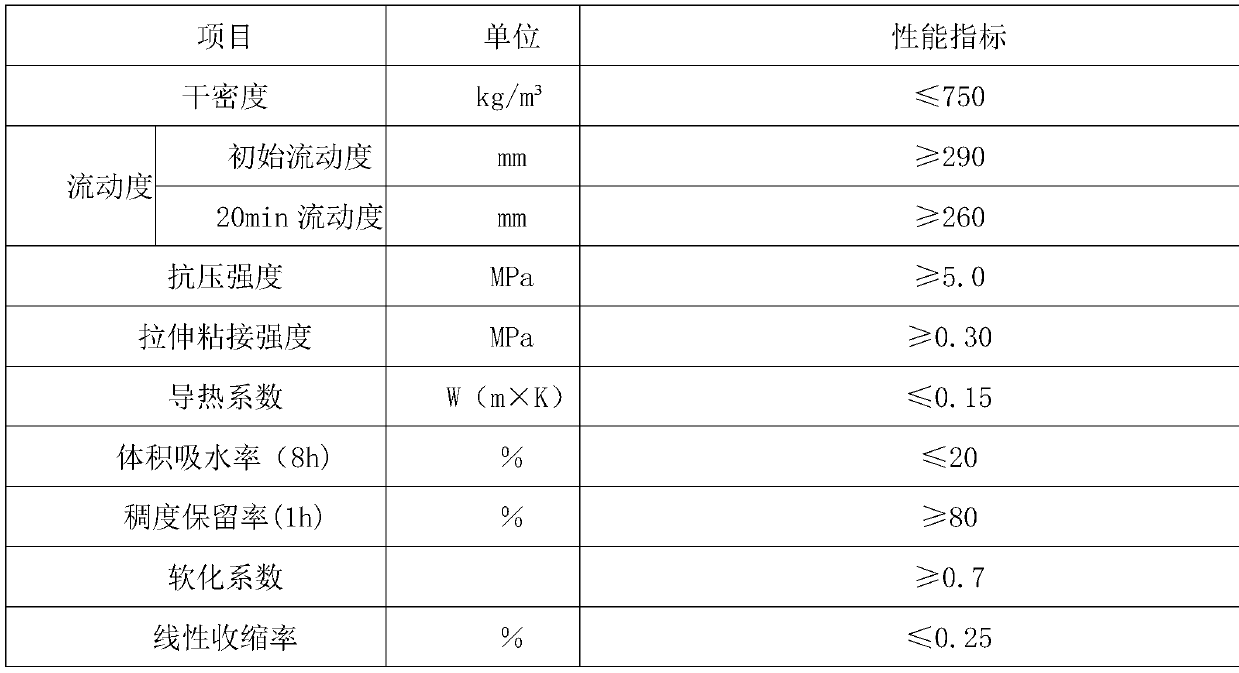

Examples

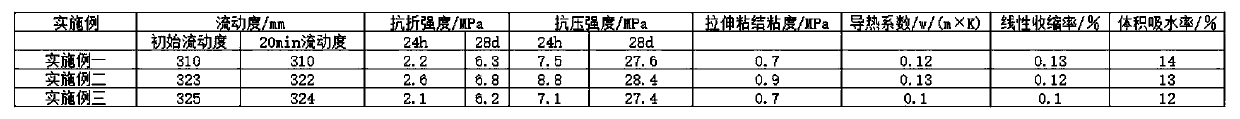

Embodiment 1

[0020] A method for preparing integrated self-leveling mortar for floor and floor insulation and leveling, comprising the following steps:

[0021] S1, obtain raw materials, 18 parts of cement, 7 parts of building gypsum, 3.5 parts of fly ash, 3.5 parts of silica fume, 15 parts of vitrified microspheres, 59 parts of aggregate, 0.22 parts of defoamer, and 0.25 part of water reducer. 3 parts of dispersed latex, 0.003 parts of cellulose ether, 0.16 parts of anti-sedimentation agent, the cement model is PII42.5 cement, the compressive strength is 44.2MPa, the initial setting time of building gypsum is 7 minutes, the final setting time is 13 minutes, and the anti-settling agent is 2h. The flexural strength is 1.9MPa, the 2h compressive strength is 4.1MPa, and the fly ash is Class 1 ash.

[0022] S2, each component material (cement material, aggregate, mineral admixture, additive) that will prepare this mortar is weighed according to proportion, aggregate quartz sand is made of 50-7...

Embodiment 2

[0028] S1. Obtain raw materials: 22 parts of ordinary Portland cement, 8 parts of phosphorus building gypsum, 6.5 parts of fly ash, 1.5 parts of silica fume, 12 parts of vitrified microspheres, 55 parts of fine aggregate river sand, and 0.16 parts of defoamer , 0.22 parts of water reducing agent, 2 parts of dispersible latex, 0.002 parts of cellulose ether, 0.12 parts of anti-sedimentation agent, the cement model is PII42.5 cement, the compressive strength is 44.2MPa, the initial setting time of building gypsum is 7 minutes, and the final The setting time is 13 minutes, the 2h flexural strength is 1.9MPa, the 2h compressive strength is 4.1MPa, and the fly ash is Class 1 ash.

[0029] S2, each component material (cement material, aggregate, mineral admixture, additive) that will prepare this mortar is weighed according to proportion, aggregate quartz sand is made of 50-70 mesh and 70-140 mesh quartz sand according to 1 : Grading by weight ratio of 1, dry mixing is sufficient, t...

Embodiment 3

[0035] S1. Get raw materials: 20 parts of ordinary Portland cement, 10 parts of phosphorus building gypsum, 7.5 parts of fly ash, 2 parts of silica fume, 16 parts of vitrified microspheres, 65 parts of fine aggregate river sand, and 0.15 parts of defoamer , 0.24 parts of water reducing agent, 2 parts of dispersible latex, 0.003 parts of cellulose ether, 0.16 parts of anti-settling agent, the cement model is PII42.5 cement, the compressive strength is 44.2MPa, the initial setting time of building gypsum is 7 minutes, and the final The setting time is 13 minutes, the 2h flexural strength is 1.9MPa, the 2h compressive strength is 4.1MPa, and the fly ash is Class 1 ash.

[0036]S2, each component material (cement material, aggregate, mineral admixture, additive) that will prepare this mortar is weighed according to proportion, aggregate quartz sand is made of 50-70 mesh and 70-140 mesh quartz sand according to 1 : Grading by weight ratio of 1, dry mixing is sufficient, the mixing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com