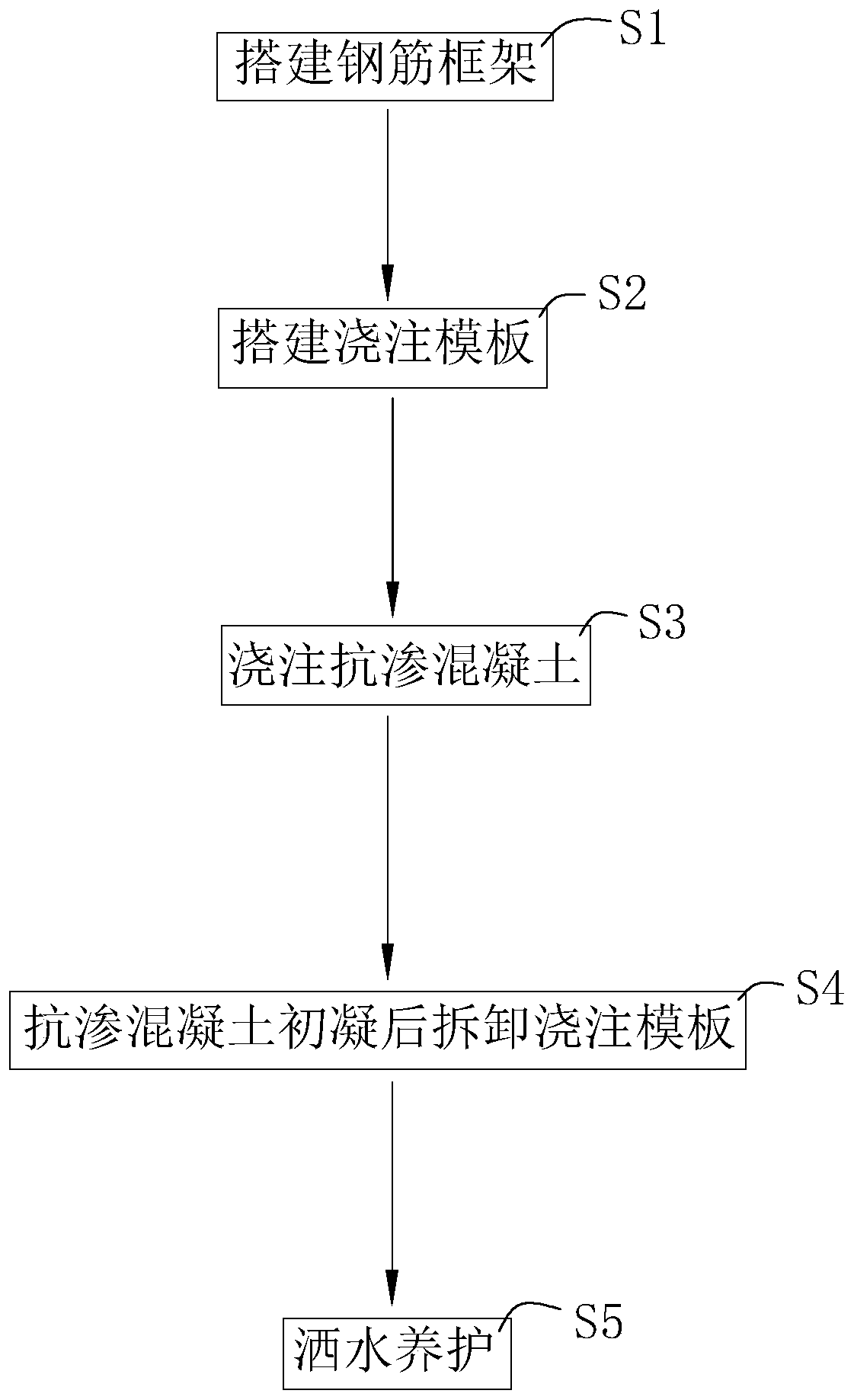

Construction method for impermeability leakage prevention of secondary structure

A construction method and secondary structure technology, applied in the field of housing construction, can solve problems such as separation and shedding, poor anti-seepage performance, and decreased anti-seepage effect of secondary structures, and achieve the effect of ensuring stability, good strength, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

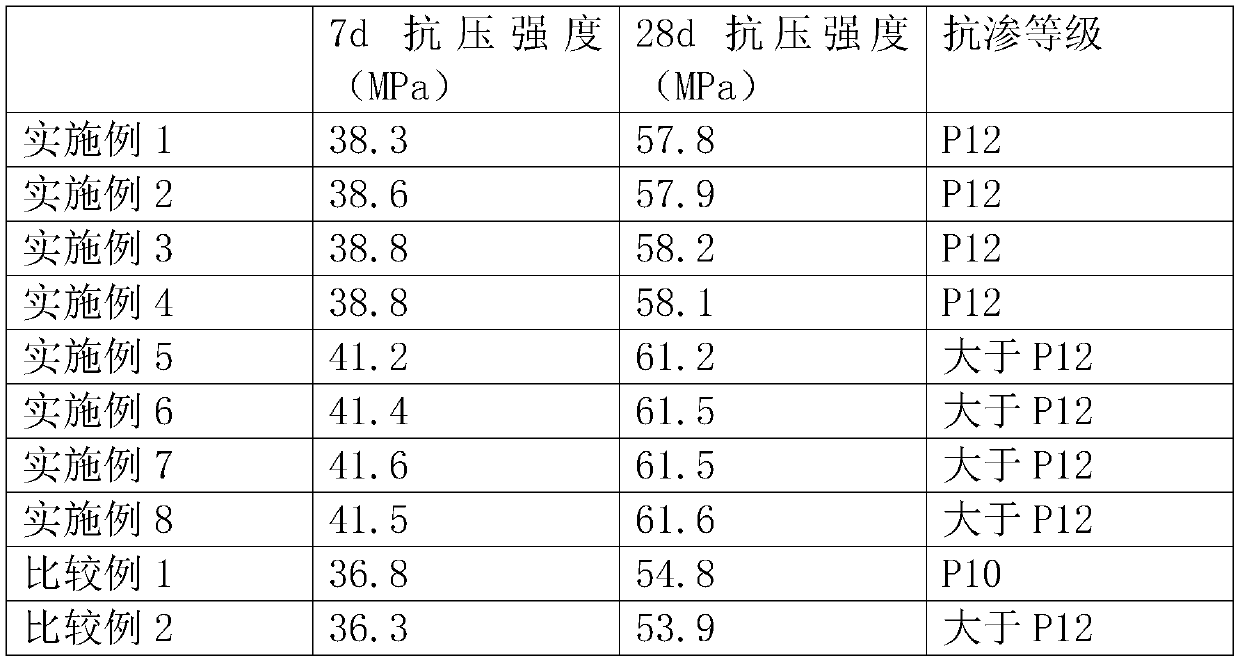

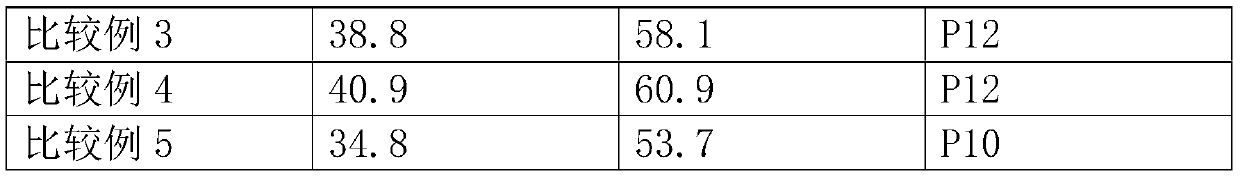

Embodiment 1

[0065] A kind of impermeable concrete, the preparation method of impermeable concrete is as follows:

[0066] a. Put silica, talc, mica, graphite, granite, and dolomite into a grinder and grind them into powders with a particle size of 10-100nm;

[0067] b. Add Portland cement 100kg, water 90kg, water reducing agent 11kg, adhesive 30kg, rotating speed 60r / min, stirring for 5min to form cement slurry in the mixing tank;

[0068] c. Add 12.5kg of nano-silica powder, 15kg of nano-talc powder, 20kg of nano-mica powder, 10kg of nano-graphite powder, 17.5kg of nano-granite powder, 25kg of nano-dolomite powder, rotating speed 60r / min, and stirring into the cement slurry 8min to form a nano-premix;

[0069] d. Add 200kg of fine aggregate to the nano premix, rotate at 50r / min, and stir for 10min to form a fine premix;

[0070] e. Add 300kg of coarse aggregate to the fine premix, rotate at 30r / min, and mix for 20min to form impermeable concrete, rotate at 10r / min, and continue to mix until it is...

Embodiment 2

[0072] A kind of impermeable concrete, the preparation method of impermeable concrete is as follows:

[0073] a. Put silica, talc, mica, graphite, granite, and dolomite into a grinder and grind them into powders with a particle size of 10-100nm;

[0074] b. Add Portland cement 100kg, water 100kg, water reducing agent 10kg, adhesive 40kg, rotating speed 60r / min, stirring for 5min to form cement slurry in the mixing tank;

[0075] c. Add 15.625kg of nano-silica powder, 18.75kg of nano-talc powder, 25kg of nano-mica powder, 12.5kg of nano-graphite powder, 21.875kg of nano-granite powder, and 31.25kg of nano-dolomite powder in the cement slurry at a speed of 60r / min, stirring for 8 min to form a nano-premix;

[0076] d. Add 225kg of fine aggregate to the nano premix, rotate at 50r / min, and stir for 10min to form a fine premix;

[0077] e. Add 350kg of coarse aggregate to the fine premix, rotate speed 30r / min, and stir for 20min to form impermeable concrete, rotate speed 10r / min, and conti...

Embodiment 3

[0079] A kind of impermeable concrete, the preparation method of impermeable concrete is as follows:

[0080] a. Put silica, talc, mica, graphite, granite, and dolomite into a grinder and grind them into powders with a particle size of 10-100nm;

[0081] b. Add Portland cement 100kg, water 110kg, water reducing agent 90kg, adhesive 50kg, rotating speed 60r / min, stirring for 5min to form cement slurry in the mixing tank;

[0082] c. Add 18.75kg of nano-silica powder, 22.5kg of nano-talc powder, 30kg of nano-mica powder, 15kg of nano-graphite powder, 26.25kg of nano-granite powder, and 37.5kg of nano-dolomite powder in the cement slurry at a speed of 60r / min , Stir for 8min to form a nano-premix;

[0083] d. Add 250kg of fine aggregate to the nano premix, rotate at 50r / min, and stir for 10min to form a fine premix;

[0084] e. Add 400kg of coarse aggregate to the fine premix at a speed of 30r / min and stir for 20min to form impermeable concrete with a speed of 10r / min, and continue stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com