A kind of cast-in-place lightweight wallboard and preparation method thereof

A light-weight wallboard and cast-in-place technology, applied in the field of building materials, to achieve the effect of realizing resource recycling, reducing consumption, and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

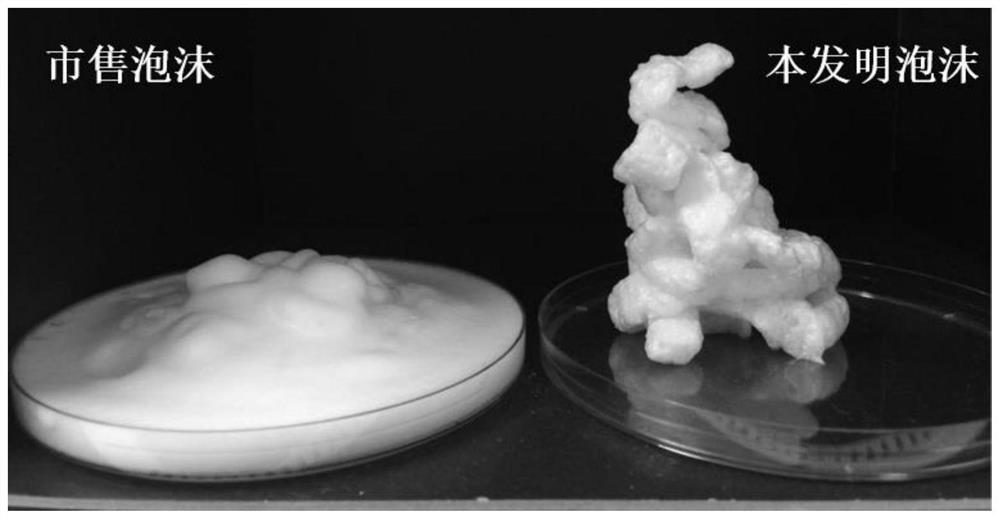

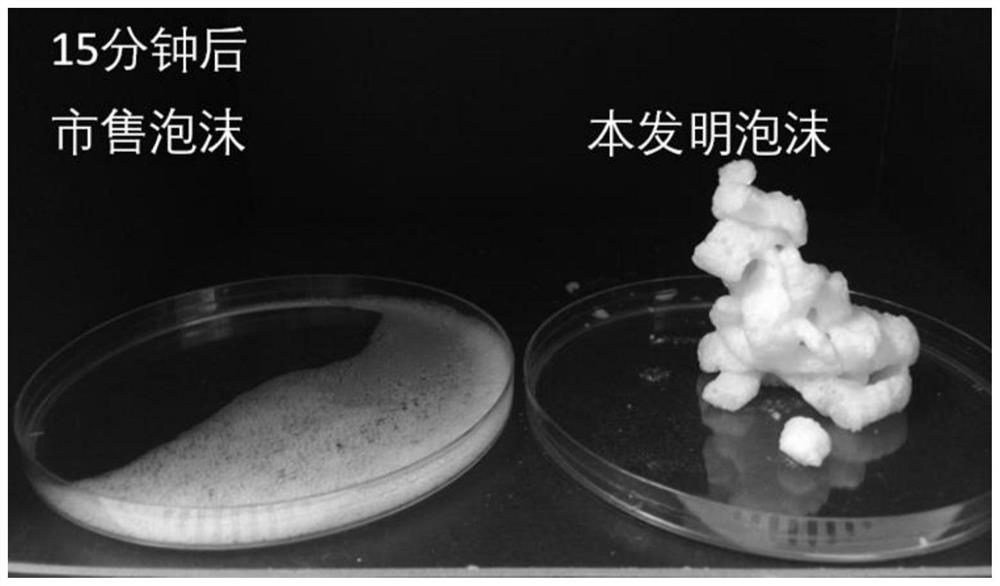

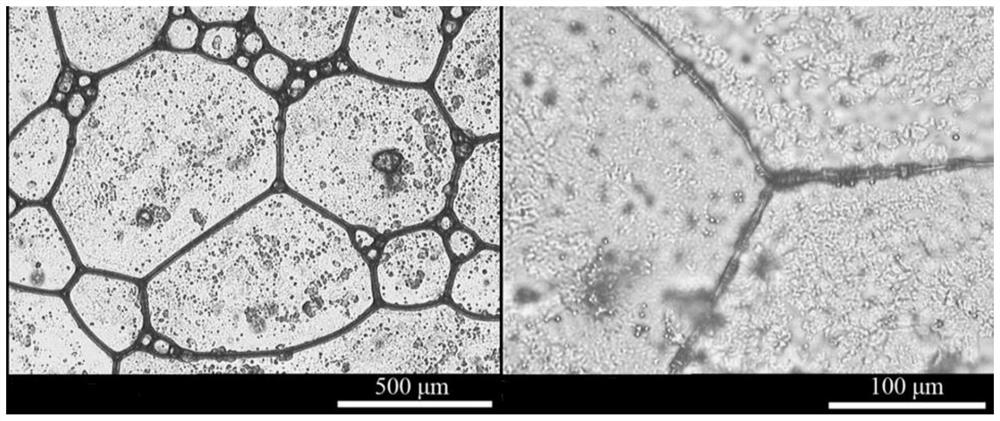

Method used

Image

Examples

Embodiment 1

[0054] The solid component of the cast-in-place lightweight wallboard of this example includes the following components by mass: 100 parts of ordinary P.O 32.5 grade cement, 40 parts of dried sludge from a water treatment plant, 15 parts of soot from a power plant, and 2 parts of shell powder , 12 parts of Class II F fly ash, 1 part of alkali-resistant glass fiber, 1 part of polycarboxylate superplasticizer, and 0.05 part of foaming agent.

[0055] The blowing agent of this example is made up of the following components by mass: 3 parts of polyacrylamide, 5 parts of polyethyleneimine, 12 parts of polyvinylpyrrolidone, 45 parts of hydroxypropyl methylcellulose, 3 parts of triethanolamine, 6 parts of surface hydrophilic modified nano-attapulgite powder, 26 parts of sodium lauryl sulfate. The foaming agent can be obtained by mixing the various foaming agent components uniformly according to the composition ratio.

[0056] The particle diameters of the dried sludge from the water...

Embodiment 2

[0063] The foaming agent used in this example is composed of the following components by mass: 4 parts of polyacrylamide, 12 parts of polyethyleneimine, 18 parts of polyvinylpyrrolidone, 40 parts of hydroxypropyl methylcellulose, 4 parts of triethanolamine , 5 parts of surface hydrophilic modified nano-kaolin powder, 17 parts of sodium dodecylbenzenesulfonate. The composition and preparation method of the remaining components are the same as in Example 1.

Embodiment 3

[0065] The foaming agent used in this example is composed of the following components by mass: 3 parts of polyacrylamide, 10 parts of polyethyleneimine, 15 parts of polyvinylpyrrolidone, 45 parts of hydroxypropyl methylcellulose, 2 parts of triethanolamine , 6 parts of surface hydrophilic modified nano-montmorillonite powder, 19 parts of AEO-9. The composition and preparation method of the remaining components are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com