A composite compacting agent

A compacting agent and composite technology, applied in the field of building materials, can solve the problems of less corrosion-resistant cement manufacturers, large fluctuations in material quality, and unstable air tightness. It is of great significance to protect the environment and improve crack resistance and seepage prevention. Effects of performance, guaranteed function and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Composite compacting agent

[0040] Weigh the raw material components as follows: silica fume (specific surface area greater than 16000m 2 / kg) 300g, double expansion source clinker (specific surface area is 300m 2 / kg) 250g, anhydrite (specific surface area is 400m 2 / kg) 200g, ethylene vinyl acetate copolymer 100g, zeolite powder (specific surface area is 500m 2 / kg) 150g. Mix and stir the various raw materials obtained by weighing to prepare a compacting agent.

[0041] Preparation of concrete test blocks

[0042] Weigh 9.2kg of cement, 10.2kg of sand, 25.0kg of gravel, and 6.2kg of water. First put water, mud and sand into the mixer, stir and mix evenly; add stones, stir evenly, add water and stir for 30-50 seconds, pour into the mold to make, standard curing, make standard test block B, as a standard concrete test block reference sample .

[0043] Weigh 200 g of the compacting agent prepared above, 9.2 kg of cement, 10.2 kg of sand, 25.0 kg of stones, and 6....

Embodiment 2

[0045] A compound compacting agent, the raw material composition is as follows: ground water-quenched blast furnace slag powder (specific surface area is 600m 2 / kg) 350g, double expansion source clinker (specific surface area is 250m 2 / kg) 350g, gypsum (specific surface area is 400m 2 / kg) 150g, vinyl acetate / tertiary carbonic acid ethylene copolymer 50g, diatomite (specific surface area is 600m 2 / kg) 100g.

[0046] Concrete standard test block A2 was prepared in the same manner as in Example 1.

Embodiment 3

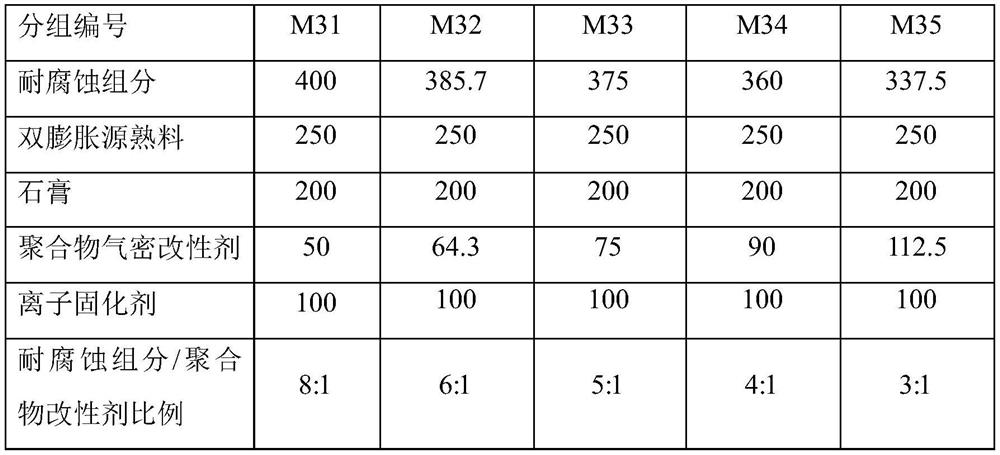

[0048] For the compound compacting agent, weigh each raw material component according to the values in the table below, mix and stir the obtained raw materials evenly, and prepare the compacting agent product.

[0049] Table 1 The mixing ratio of various raw material components in the compacting agent (unit gram)

[0050]

[0051] Among them, the corrosion-resistant component is ultra-fine slag powder, with a specific surface area of 500m 2 / kg, the specific surface area of the double expansion source clinker is 240 m 2 / kg: gypsum is dihydrate gypsum, specific surface area is 450m 2 / kg: Polymer airtight modifier is vinyl acetate / tertiary carbonic acid ethylene copolymer; ion curing agent is zeolite powder, specific surface area is 700m 2 / kg.

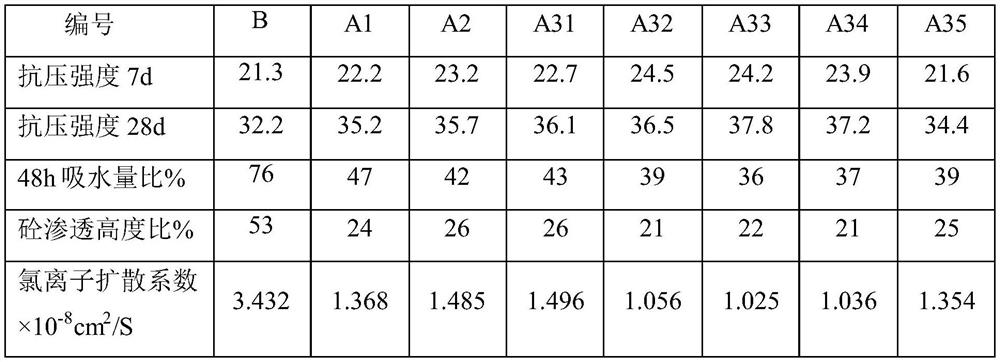

[0052] Concrete standard test blocks A31, A32, A33, A34, and A35 were prepared in the same manner as in Example 1 by using the above compacting agents M31-M35.

[0053]

[0054] The concrete standard test block and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com