Method for rapid impurity-free reduction of graphene oxide

A graphene and impurity-free technology, which is applied in the field of rapid and impurity-free reduction of graphene oxide, can solve the problems of high energy consumption, long time consumption, and reduced graphene quality, and achieve high specific surface area, difficult agglomeration, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

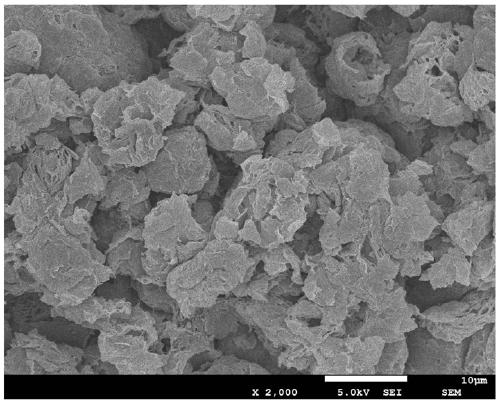

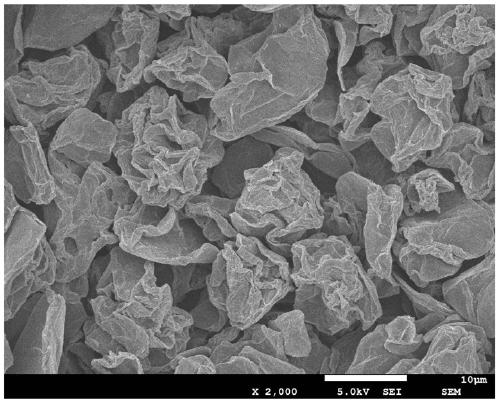

Image

Examples

Embodiment 1

[0031] The method for fast impurity-free reduction of graphene oxide comprises the following steps:

[0032] 1. Place 5g of graphene oxide in a vacuum oven, and evacuate the oven at room temperature until the pressure inside the oven reaches 5000Pa;

[0033] 2. Set the temperature and heating rate of the vacuum oven to 200°C and 10°C / min, respectively, to heat the graphene oxide;

[0034] 3. Keep the temperature of the oven for 2 hours to fully heat the graphene oxide;

[0035] 4. Stop heating, and after the temperature of the oven drops to room temperature, open the vacuum valve and collect the powder to obtain reduced graphene oxide.

Embodiment 2

[0037] The method for fast impurity-free reduction of graphene oxide comprises the following steps:

[0038] 1. Place 5g of graphene oxide in a vacuum oven, and evacuate the oven at room temperature until the pressure inside the oven reaches 10,000Pa;

[0039] 2. Set the vacuum oven temperature and heating rate to 250°C and 10°C / min, respectively, to heat the graphene oxide;

[0040] 3. Keep the temperature of the oven for 1 hour to fully heat the graphene oxide;

[0041] 4. Stop heating, and after the temperature of the oven drops to room temperature, open the vacuum valve and collect the powder to obtain reduced graphene oxide.

Embodiment 3

[0043] The method for fast impurity-free reduction of graphene oxide comprises the following steps:

[0044] 1. Place 5g of graphene oxide in a vacuum oven, and evacuate the oven at room temperature until the pressure inside the oven reaches 5000Pa;

[0045] 2. Set the vacuum oven temperature and heating rate to 250°C and 10°C / min, respectively, to heat the graphene oxide;

[0046] 3. Keep the oven temperature for 0.5h to fully heat the graphene oxide;

[0047] 4. Stop heating, and after the temperature of the oven drops to room temperature, open the vacuum valve and collect the powder to obtain reduced graphene oxide.

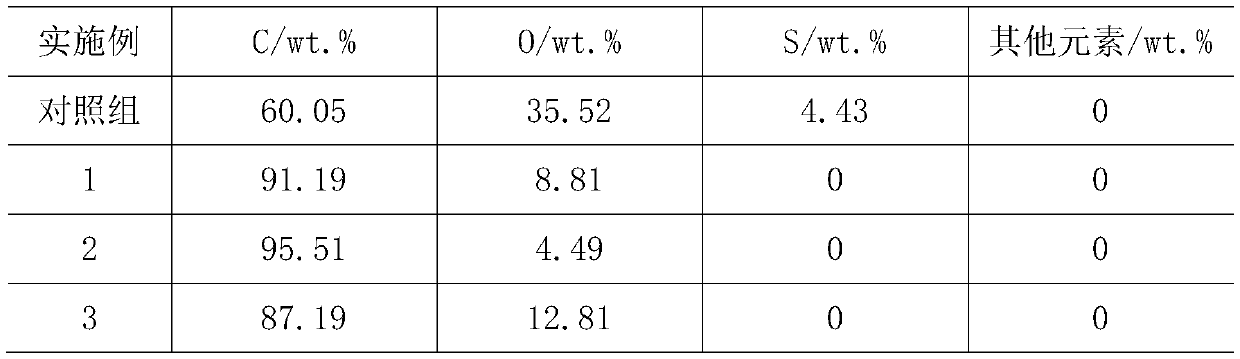

[0048] Table 1 is the result of verifying the composition change of graphene oxide before and after the implementation of the present invention.

[0049] Table 1

[0050]

[0051] As can be seen from Table 1, comparing the measured data of the control group with the measured data of Examples 1 to 3, it can be concluded that the present invention can redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com