Heat forming device

A technology of thermoforming and forming pads, which is applied in the field of thermoforming devices, can solve the problem that the edge of the barrel-shaped film cannot achieve smooth transition, etc., and achieve the effect of filling the technical gap and saving the waste of edge materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

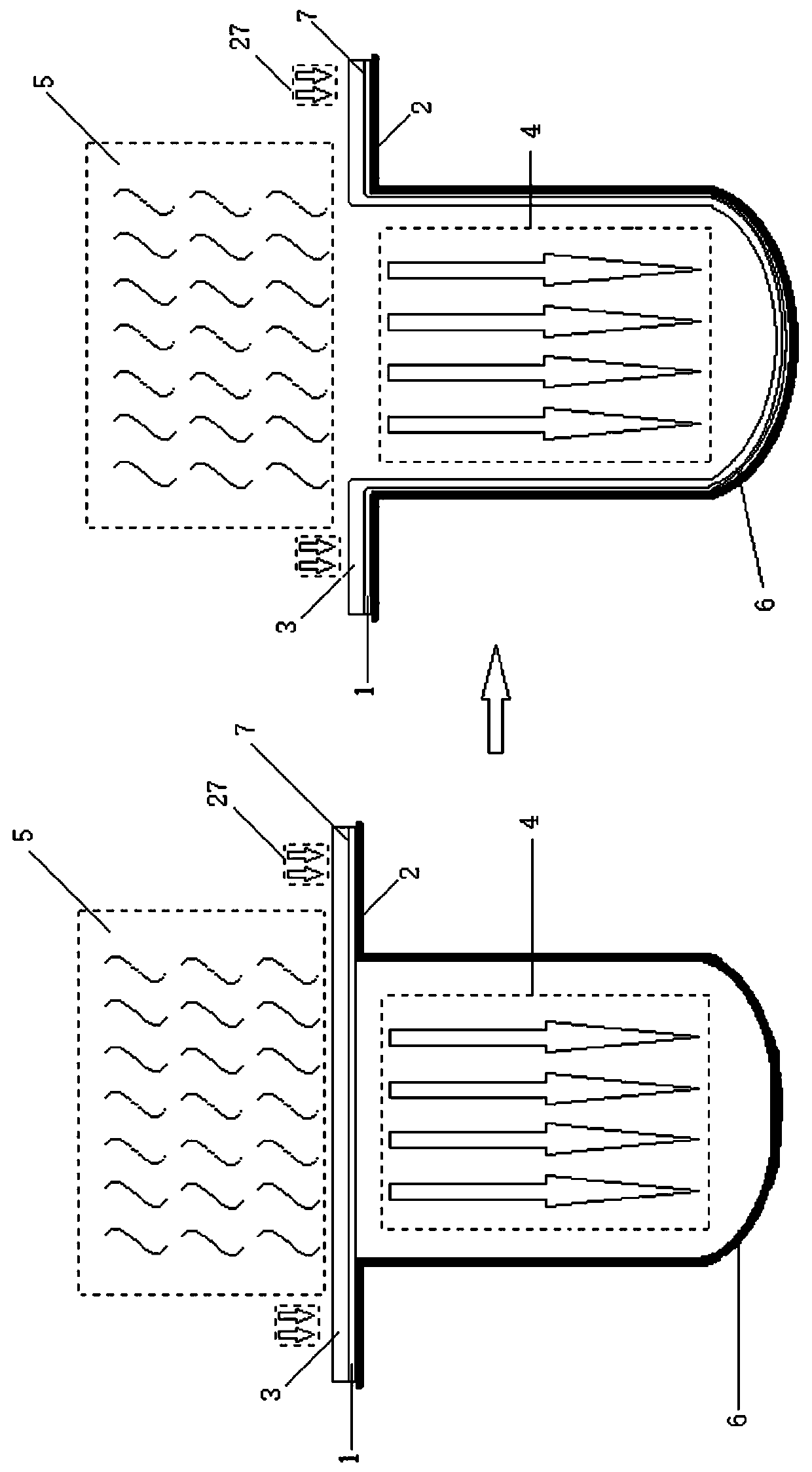

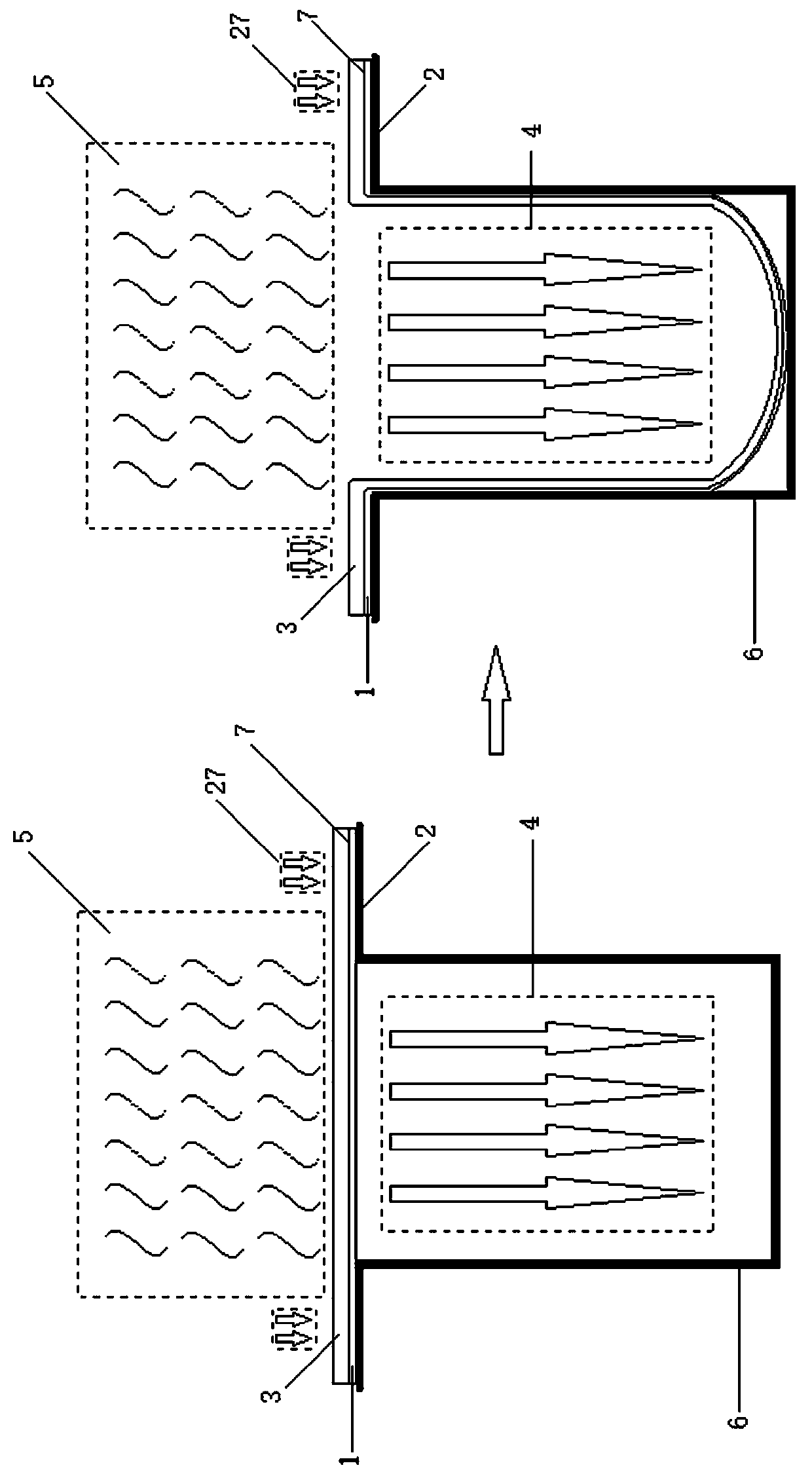

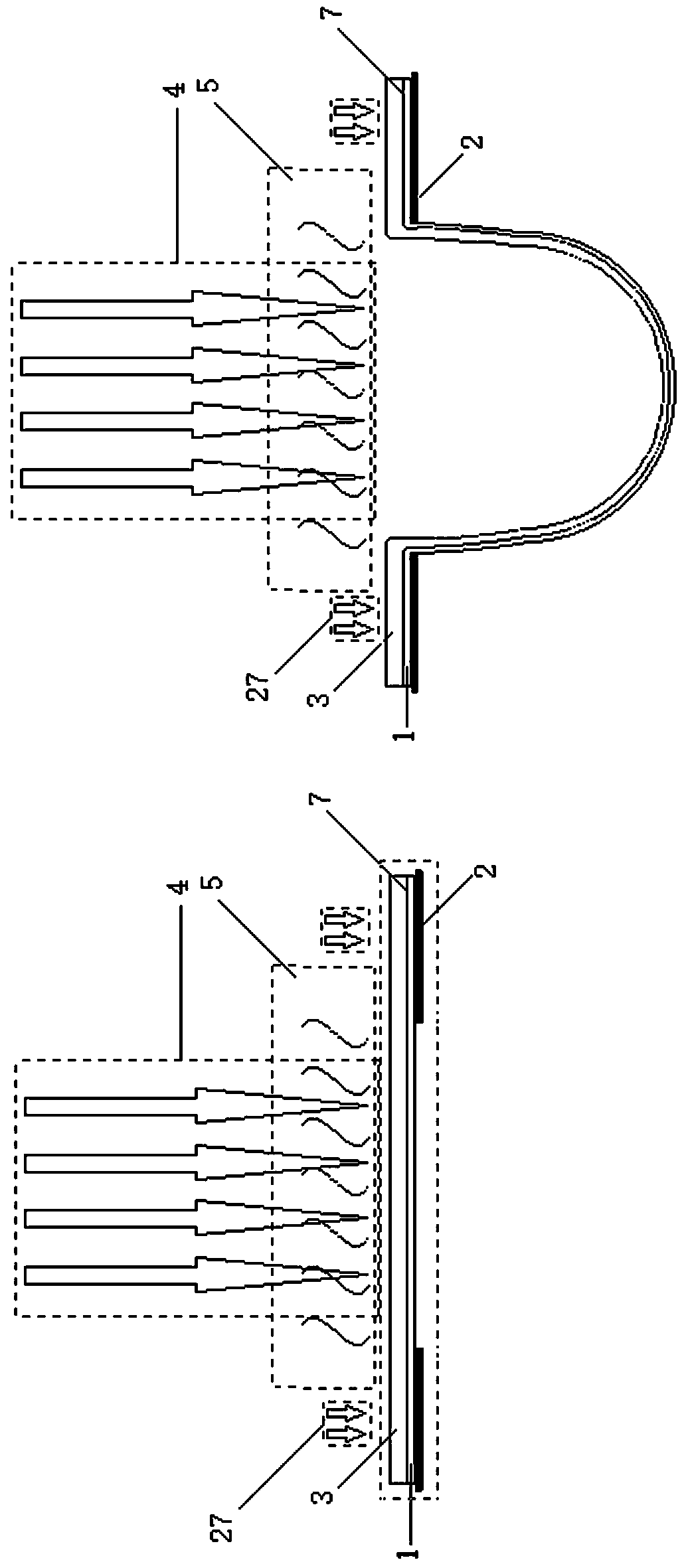

[0026] like image 3 As shown, a thermoforming device includes a forming mold, an elastic carrying pad 3, a pressurizing unit 4, a heating unit 5, and a compression sealing device 27; the forming mold is provided with a forming gasket ring 2; the elastic The carrying pad 3 and the sheet to be thermoformed 1 are tightly bonded to form a synchronous assembly 7; the synchronous assembly 7 is compressed and sealed with the forming gasket ring 2 through the compression sealing device 27, and the area to be deformed of the synchronous assembly 7 and the forming gasket ring The forming inlets of 2 are aligned; the pressure output end of the pressurizing unit 4 and the heat output end of the heating unit 5 both output and act on the area to be deformed of the synchronous assembly 7, and the pressure provided by the pressurizing unit 4 is dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com