Welding slag fire welding and annealing device, permanent magnet gap determination method and slag removing tool

An annealing device and permanent magnet technology, applied in the field of slag cleaning tools and welding slag fire annealing devices, can solve problems such as hidden dangers of personal injury, hidden dangers of fire, difficult cleaning of fusion, splashing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

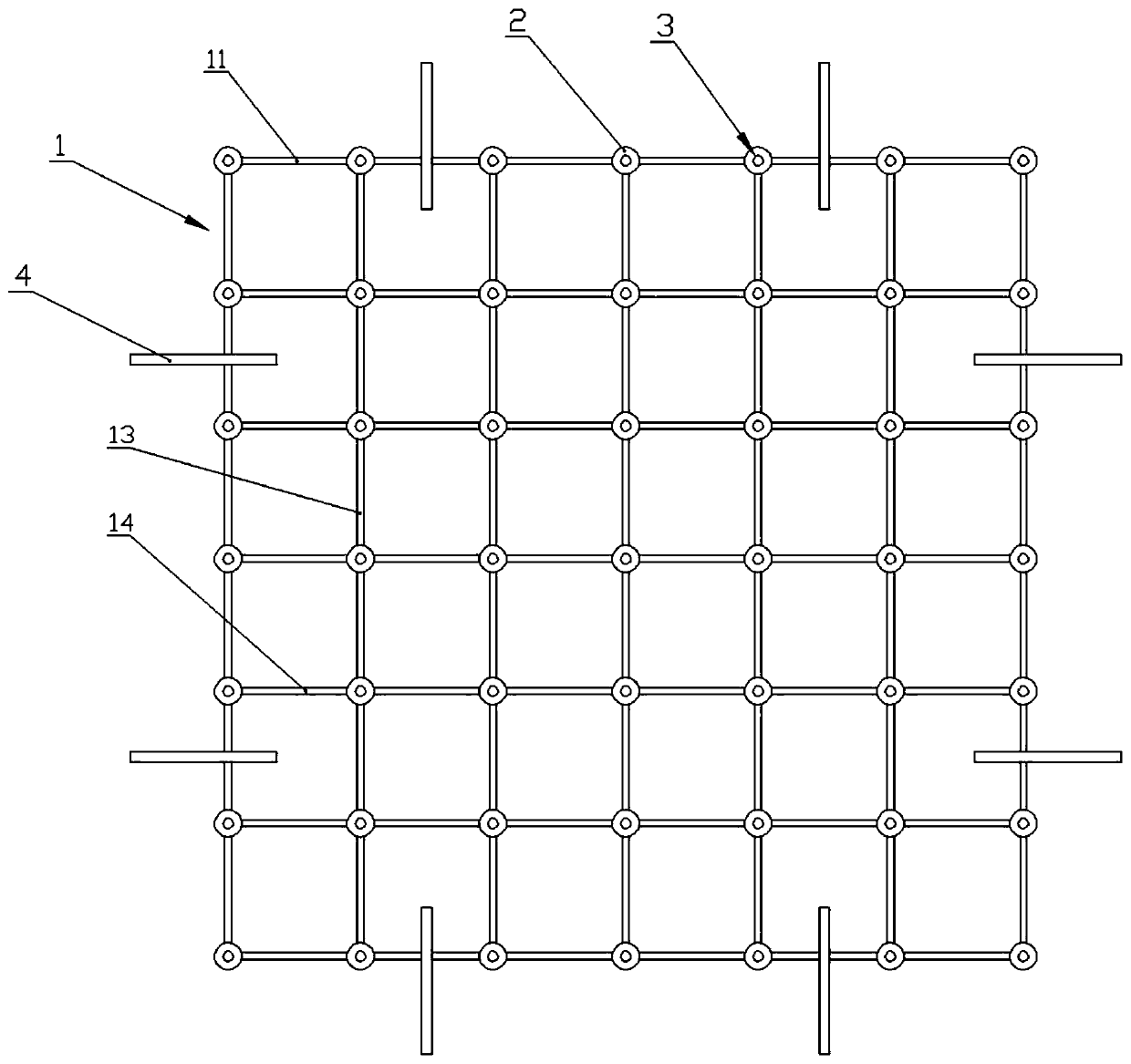

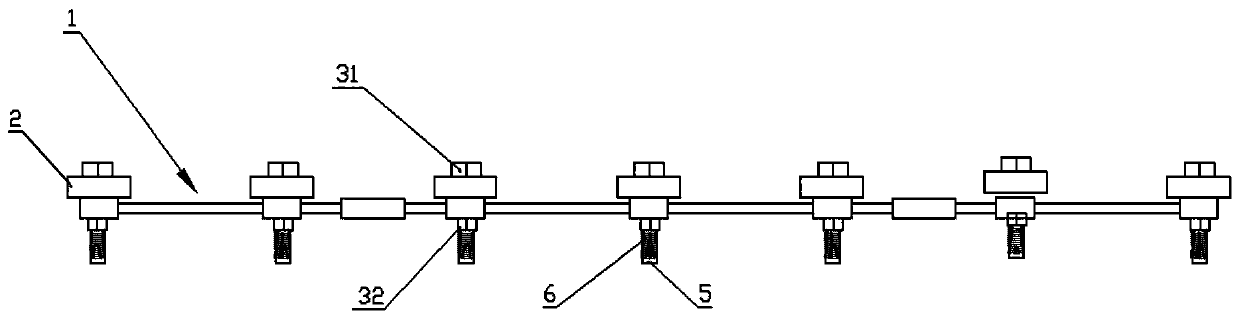

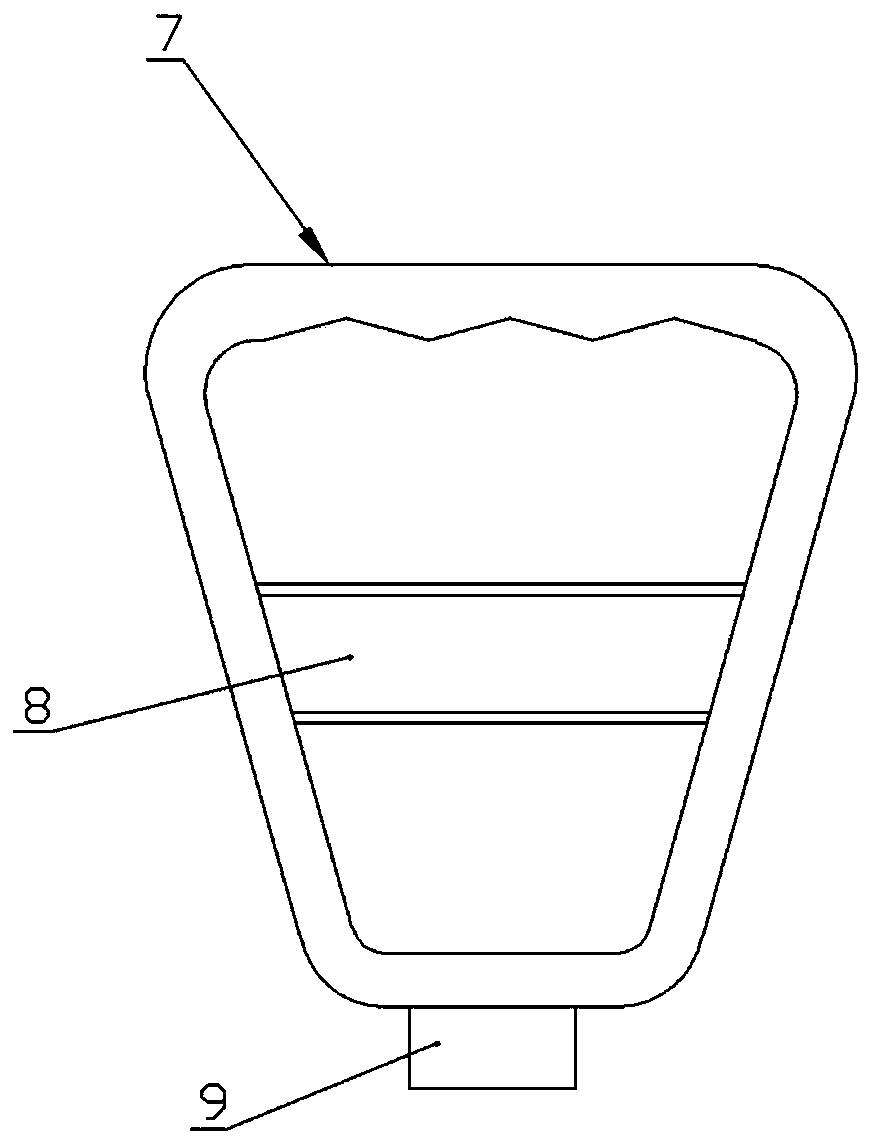

[0061] Such as figure 1 As shown, the welding slag annealing device disclosed in this embodiment includes a magnetic attraction grid 1 , a permanent magnet 2 , a locking assembly 3 and a hook 4 .

[0062] The magnetic suction grid 1 is a mesh grid made of insulating and high-temperature resistant industrial plastics, including a frame 11, a positioning seat 12, a vertical grid bar 13 and a horizontal grid bar 14; the frame is a rectangular frame; the positioning seat 12 is a circle Cylindrical seat body, there are three types of positioning seats with different heights, one is high magnetic point positioning seat A, one is medium magnetic point positioning seat B, and the other is low magnetic point positioning seat C; The grid bars 13 and the horizontal grid bars 14 are arranged in a staggered manner in the frame, and the inner area of the frame is composed of multiple unit modules; The high magnetic point positioning seat A and the low magnetic point positioning seat C ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com