Tin welding machine equipment

A soldering machine and equipment technology, applied in the direction of welding equipment, metal processing equipment, auxiliary devices, etc., can solve the problems of low soldering efficiency and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Embodiment 1, the concrete structure of the present invention is as follows:

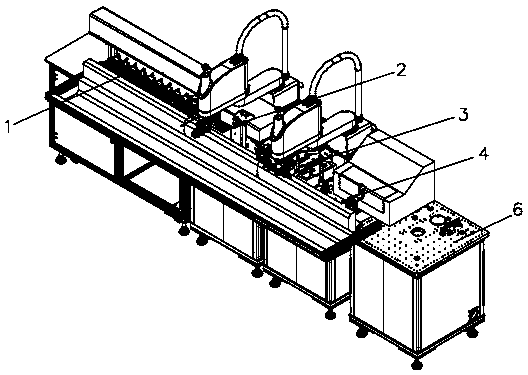

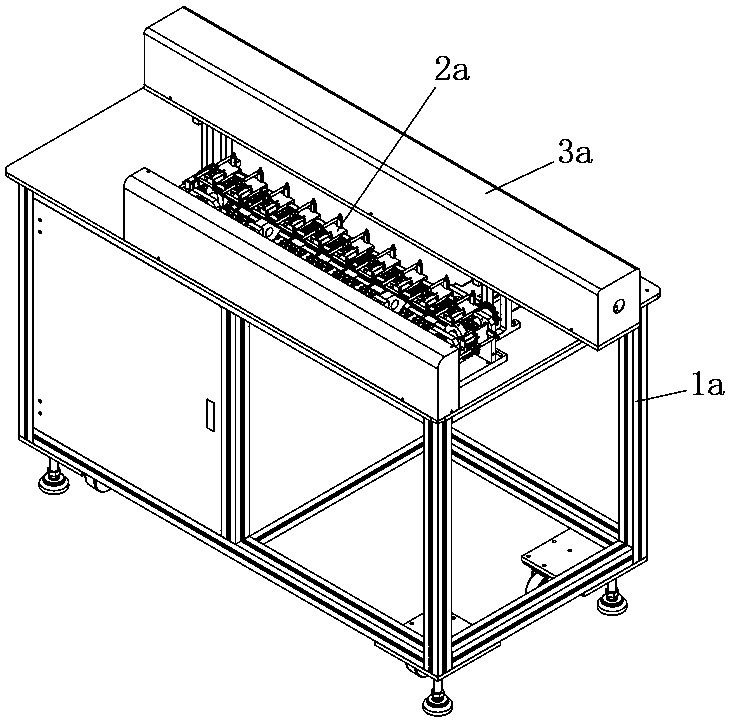

[0088] Please refer to the attached Figure 1-22 , a kind of soldering machine equipment of the present invention, this soldering machine equipment comprises:

[0089] One is located at the feeding buffer device 2a on the first frame 1a, comprises a chain conveyor belt 29a and drives described chain conveyor belt 29a to do the 4th driving mechanism of intermittent rotation, and described chain conveyor belt 29a is provided with etc. The wire clamping assembly 24a used for clamping the wire, the wire clamping assembly 24a moves with the chain conveyor belt 29a, and the wire clamping assembly 24a moves along a pair of first slide rails 25a when moving upward ;

[0090] A wire stripping mechanism 2b arranged on the second frame 7b, the upper end of the second frame 7b is provided with a first platform, the stripping mechanism 2b includes a first four-axis manipulator 1b, a pre-cut assembly 3b, a...

Embodiment 2

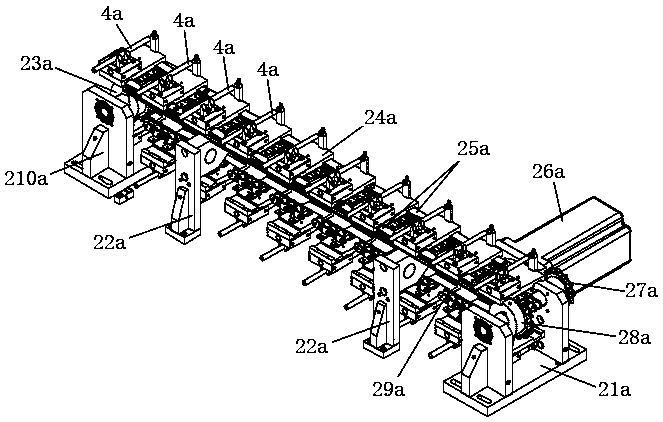

[0095] Such as Figure 2-4 As shown, the working principle of the loading buffer device 2a is as follows:

[0096] The two ends of the chain conveyor belt 29a are respectively sleeved on the driving gear 28a and the first driven gear 23a, wherein: the driving gear 28a is sleeved on a rotating shaft, and the rotating shaft is set on a right chain support 21a and its One end passes through the side plate of the right chain bracket 21a and the end is fixed with a second driven gear 27a, which is driven to rotate by the fourth drive mechanism; the first driven gear 23a covers Connected on a rotating shaft, the rotating shaft is mounted on a left chain support 210a; the fourth driving mechanism is a stepping motor 26a, and the driving end of the stepping motor 26a is connected to a gear, which is connected to the second driven gear 27a is provided with synchronous belt.

[0097] The wire clamping assembly 24a includes:

[0098] A fixture mounting plate, the left and right sides ...

Embodiment 3

[0106] Such as Figure 5-15 , the following is the structure and operating principle of the wire stripping mechanism 2b:

[0107] 1. The structure of wire stripping mechanism 2b is as follows:

[0108] The first four-axis manipulator 1b includes a motor 11b, a rocker arm 12b, a limit elbow 15b, a claw mounting arm 13b and a height adjuster 14b, and the motor 11b is vertically fixed on the first platform, and its driving The rocker arm 12b is connected upwards, the swing arm 12b moves in a horizontal plane, and the upper side of the other end is pivotally connected to the mechanical claw installation arm 13b, and the mechanical claw installation arm 13b is away from one end of the swing arm 12b A height adjuster 14b that can be adjusted in height is installed in the clip hole, and a rotatable limit elbow 15b is connected between the upper end of one end of the rocker arm 12b and the housing of the motor 11b. The height adjuster The lower end of 14b is connected to the jaw ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com