Egg white powder enzymatic modification method

A technology of egg white powder and enzymatic method, which is applied in the field of food processing, can solve the problems of affecting the quality of egg white powder and reducing the foamability of egg white, and achieve the effects of improving appearance and taste, improving foaming performance and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

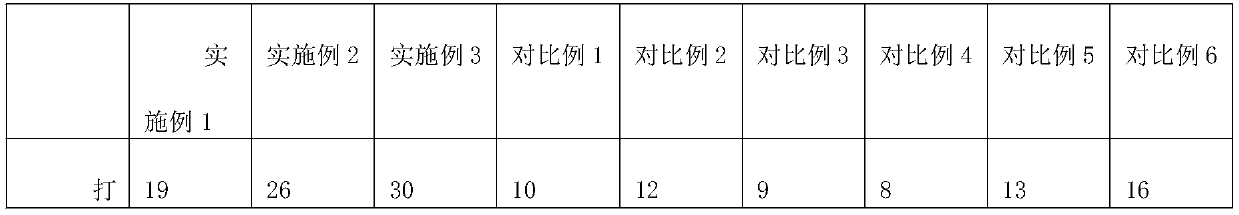

Examples

Embodiment 1

[0040] A method for enzymatic modification of egg white powder, comprising the following steps:

[0041] 1) Select fresh eggs, crack the shell, separate the egg white and egg yolk, and set aside;

[0042] 2) Add egg yolk to the egg white, the amount of egg yolk added accounts for 0.3% of the mass of the egg white liquid, stir slowly with a mixer so that the egg yolk is evenly dispersed in the egg white, and the egg white liquid is obtained for use;

[0043] 3) Add compound enzyme in egg white liquid, compound enzyme comprises 20wt% protease and 80wt% lipase; Protease comprises the zein enzyme of 20 weight parts, the bromelain of 10 weight parts, the yeast protease of 10 weight parts and the mold of 2 weight parts Protease; lipase comprises the pyrophosphatase of 20 weight parts, the hexose-6-phosphatase of 10 weight parts and the carboxylesterase of 10 weight parts; Stir slowly at high temperature for 2 hours to carry out the enzymolysis reaction, the temperature of the enzym...

Embodiment 2

[0047] A method for enzymatic modification of egg white powder, comprising the following steps:

[0048] 1) Select fresh eggs, crack the shell, separate the egg white and egg yolk, and set aside;

[0049] 2) Add egg yolk to the egg white, the amount of egg yolk added accounts for 0.4% of the mass of the egg white liquid; stir at a slow speed with a mixer so that the egg yolk is evenly dispersed in the egg white, and the egg white liquid is obtained for use;

[0050] 3) add compound enzyme in egg white liquid, compound enzyme comprises 25wt% protease and 75wt% lipase; Protease comprises the zein enzyme of 30 weight parts, the bromelain of 12 weight parts, the yeast protease of 13 weight parts and the mold of 3 weight parts Protease; lipase comprises the pyrophosphatase of 30 weight parts, the hexose-6-phosphatase of 12 weight parts and the carboxylesterase of 11 weight parts; The reaction temperature is 30°C, and the enzymolysis reaction is carried out by stirring slowly for 8...

Embodiment 3

[0054] A method for enzymatic modification of egg white powder, comprising the following steps:

[0055] 1) Select fresh eggs, crack the shell, separate the egg white and egg yolk, and set aside;

[0056] 2) Add egg yolk to the egg white, the amount of egg yolk added accounts for 0.5% of the mass of the egg white liquid, stir at a slow speed with a mixer so that the egg yolk is evenly dispersed in the egg white, and the egg white liquid is obtained for use;

[0057] 3) add compound enzyme in egg white liquid, compound enzyme comprises 30wt% protease and 70wt% lipase; Protease comprises the zein enzyme of 40 weight parts, the bromelain of 15 weight parts, the yeast protease of 15 weight parts and the mold of 4 weight parts Protease; Lipase comprises the pyrophosphatase of 40 weight parts, the hexose-6-phosphatase of 15 weight parts and the carboxylesterase of 15 weight parts; The addition of compound enzyme accounts for 0.1% of egg white liquid quality, at certain Stir slowly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com