Display screen and display device comprising display screen

A display and encapsulation layer technology, applied in the field of OLED displays, can solve problems such as high cost, cumbersome process, and affecting product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

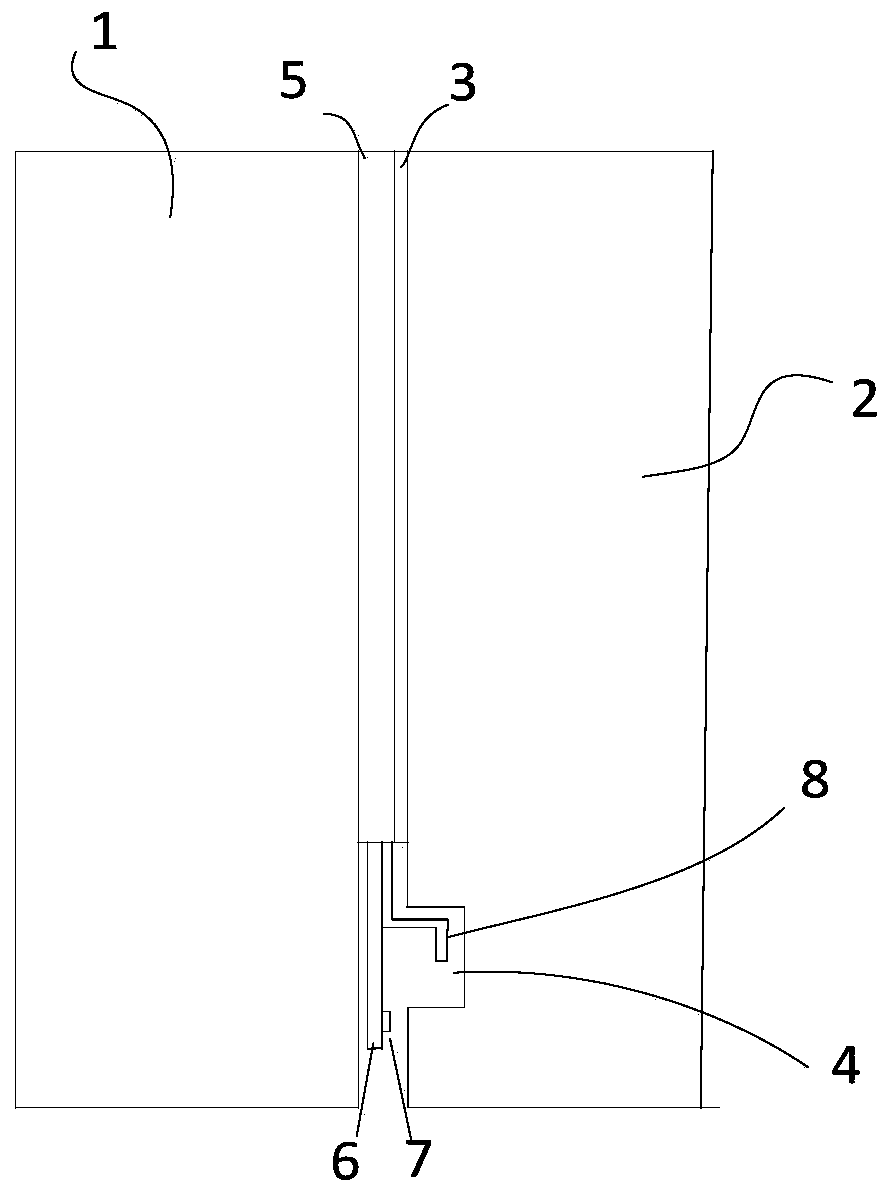

[0047] This embodiment provides a display body, such as figure 1 As shown, it includes a substrate 1 and an anode layer, an organic light-emitting layer, a cathode layer and an encapsulation layer 2 stacked on the surface of the substrate 1 in sequence, and also includes: a groove 4 arranged on the encapsulation layer 2 close to the cathode layer At least one anode conductive coating 7 and at least one cathode conductive coating 8 are arranged in the groove 4 or on the top of the groove; the electrode lead area 6 is arranged on the side of the substrate 1 close to the encapsulation layer 2 , the electrode lead region 6 includes at least one anode lead region 9 and at least one cathode lead region 10, the anode layer is connected to the anode lead region 9 through the anode conductive coating 7, and the cathode layer is connected to the anode lead region 9 through the anode layer The cathode conductive coating 8 is connected to said cathode lead region 10 .

[0048] Specifical...

Embodiment 2

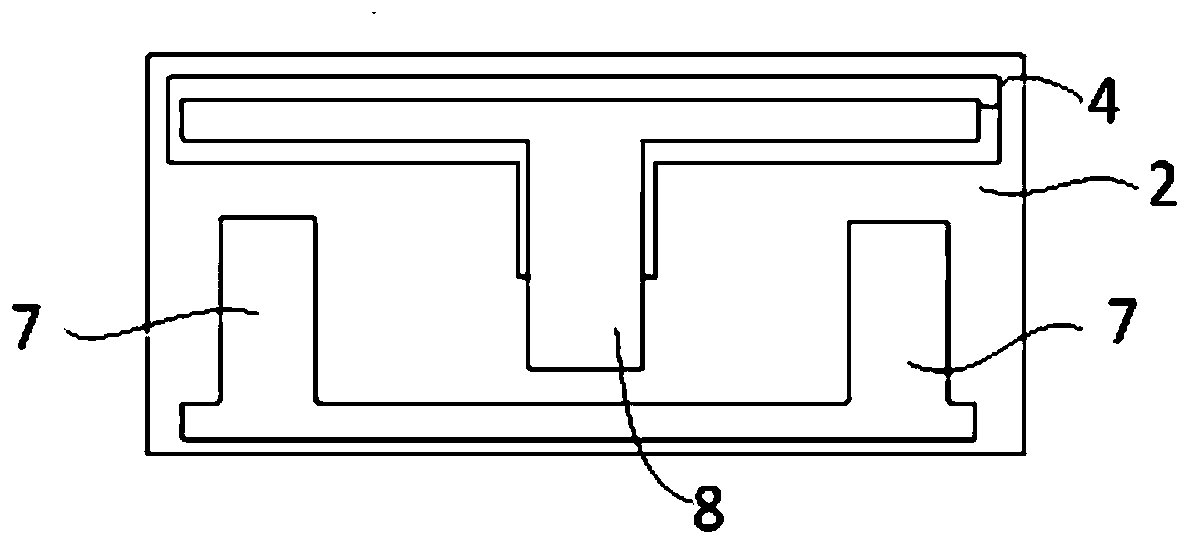

[0050] This embodiment provides a display body. On the basis of the first embodiment above, the electrode lead region 6 is disposed near one end of the substrate 1 , and the electrode lead region 6 is disposed opposite to the groove 4 . Such as image 3 As shown, the anode lead region 9 is arranged on both sides of the electrode lead region 6 , and the cathode lead region 10 is arranged in the middle of the electrode lead region 6 . Optionally, the cathode lead region 10 is located at the central axis of the electrode lead region 6 .

[0051] Further, such as figure 2 As shown, two anode conductive coatings 7 and one cathode conductive coating 8 are arranged in the groove 4 or on the top of the groove. Optionally, the two anode conductive coatings 7 are correspondingly connected to two anode lead regions 9 , and the cathode conductive coating 8 is connected to the cathode lead region 10 . Optionally, the anode conductive coating 7 or the cathode conductive coating 8 has an...

Embodiment 3

[0054] This embodiment provides a display body, on the basis of the above-mentioned embodiments 1 and 2, such as Figure 4 As shown, the display screen body 14 includes at least two, and the exterior of the display screen body 14 is respectively provided with an anode conductive point 12 and a cathode conductive point 11, and the anode conductive point 12 is connected to the anode lead area 9 and an external power supply 13, the cathode conductive point 11 connects the cathode lead area 10 and the negative pole of the external power supply 13.

[0055] Further, when the OLED large substrate contains a plurality of the above-mentioned display screen bodies 14, the multiple display screen bodies 14 are arranged in a matrix on the large substrate, and on both sides of the row direction, a plurality of display screen bodies 14 are arranged outside the display screen body 14. An anode conductive point 12 and a cathode conductive point 11, each anode conductive point 12 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com