High-frequency high-saturation-flux-density ferrite, preparation method, inductor and transformer

A technology of magnetic flux density and ferrite, which is used in the manufacture of inductors/transformers/magnets, transformer/inductor components, circuits, etc. The effect of improving the superposition characteristics, reducing the volume, and reducing the total loss of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

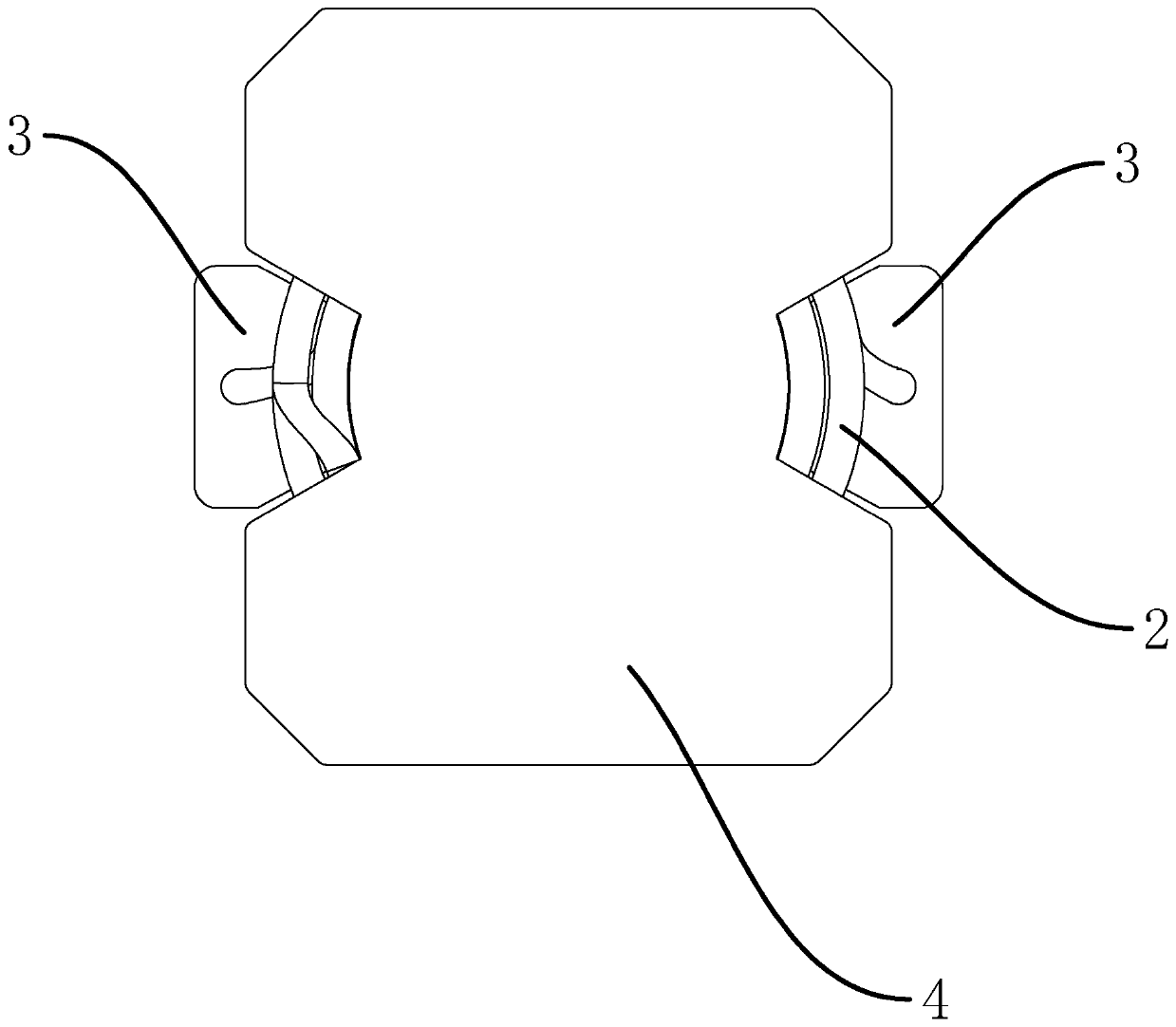

Image

Examples

Embodiment 1

[0062] A method for preparing a high-frequency ultra-high saturation magnetic flux density manganese-zinc ferrite material and an inductor. The ferrite material is composed of a main component and an auxiliary component, and the main component is Fe 2 o 3 : 55.0mol%, ZnO: 3.2mol%, balance MnO; secondary component Nb 2 o 5 : 0.02wt%, CaCO 3 : 0.03wt%, V 2 o 5 : 0.02wt%, TiO 2 : 0.01wt%, Ta 2 o 5 :0.01wt%, Co 2 o 3 : 0.15wt%, the above sub-components are based on Fe 2 o 3 , ZnO, the total weight percentage of MnO is calculated.

[0063] A preparation method of a high-frequency ultra-high saturation magnetic flux density manganese-zinc ferrite material comprises the following steps:

[0064] 1) Ingredients: According to the main formula Fe 2 o 3 , ZnO and MnO ratios were weighed and mixed for sanding, and the sanding time was 15 minutes;

[0065] 2) Pre-burning: pre-burn the mixed powder, the pre-burning temperature is 900°C, and keep warm for 2 hours;

[0066] 3)...

Embodiment 2

[0074] A method for preparing a high-frequency ultra-high saturation magnetic flux density manganese-zinc ferrite material and an inductor. The ferrite material is composed of a main component and an auxiliary component, and the main component is Fe 2 o 3 : 55.5mol%, ZnO: 2.8mol%, MnO 41.7mol%; secondary component Nb 2 o 5 : 0.02wt%, CaCO 3 : 0.05wt%, V 2 o 5 : 0.03wt%, TiO 2 : 0.01wt%, Ta 2 o 5 :0.01wt%, Co 2 o 3 : 0.15wt%, the above sub-components are based on Fe 2 o 3 , ZnO, the total weight percentage of MnO is calculated.

[0075] A preparation method of a high-frequency ultra-high saturation magnetic flux density manganese-zinc ferrite material comprises the following steps:

[0076] 1) Ingredients: According to the main formula Fe 2 o 3 , ZnO and MnO ratios were weighed and mixed for sanding, and the sanding time was 15 minutes;

[0077] 2) Pre-burning: pre-burn the mixed powder, the pre-burning temperature is 900°C, and keep warm for 2 hours;

[0078] 3...

Embodiment 3

[0086] A method for preparing a high-frequency ultra-high saturation magnetic flux density manganese-zinc ferrite material and an inductor. The ferrite material is composed of a main component and an auxiliary component, and the main component is Fe 2 o 3 : 55.0mol%, ZnO: 3.2mol%, balance MnO; secondary component Nb 2 o 5 : 0.02wt%, CaCO 3 : 0.03wt%, V 2 o 5 : 0.02wt%, TiO 2 : 0.01wt%, Ta 2 o 5 :0.01wt%, Co 2 o 3 : 0.15wt%, the above sub-components are based on Fe 2 o 3 , ZnO, the total weight percentage of MnO is calculated.

[0087] A preparation method of a high-frequency ultra-high saturation magnetic flux density manganese-zinc ferrite material comprises the following steps:

[0088] 1) Ingredients: According to the main formula Fe 2 o 3 , ZnO and MnO ratios were weighed and mixed for sanding, and the sanding time was 15 minutes;

[0089] 2) Pre-burning: pre-burn the mixed powder, the pre-burning temperature is 900°C, and keep warm for 2 hours;

[0090] 3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| saturation flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com