Method for predicting and maintaining condensation performance of solar disc type condensation system

A technology of concentrating system and solar energy, applied in the field of solar concentrating utilization, can solve the problems of structural deformation, unbalanced solar radiation energy, deterioration of focusing performance and radiation energy flow distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0080] The present invention comprises the steps:

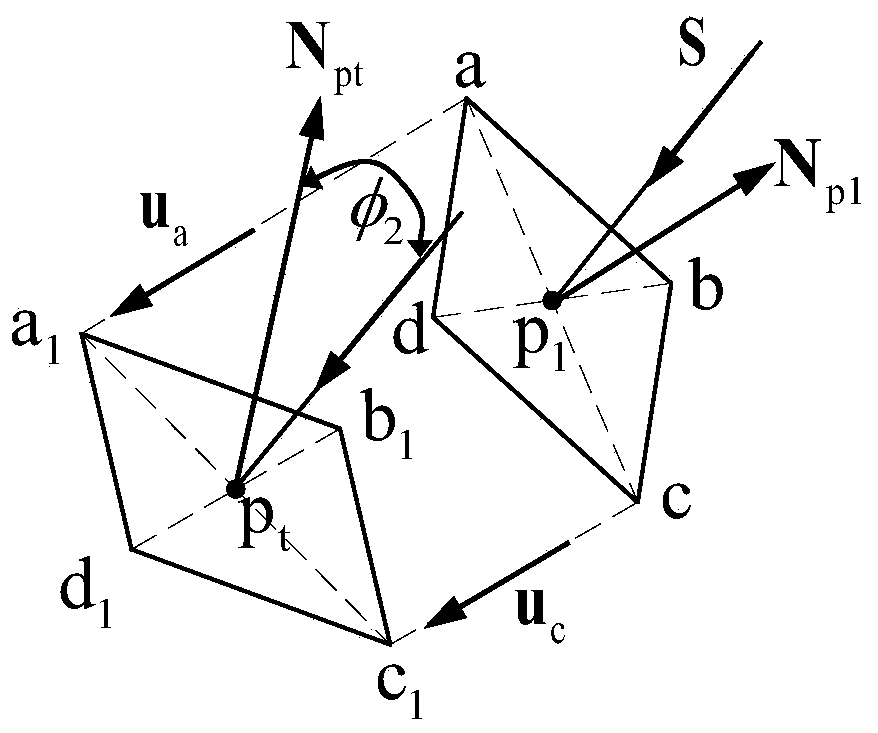

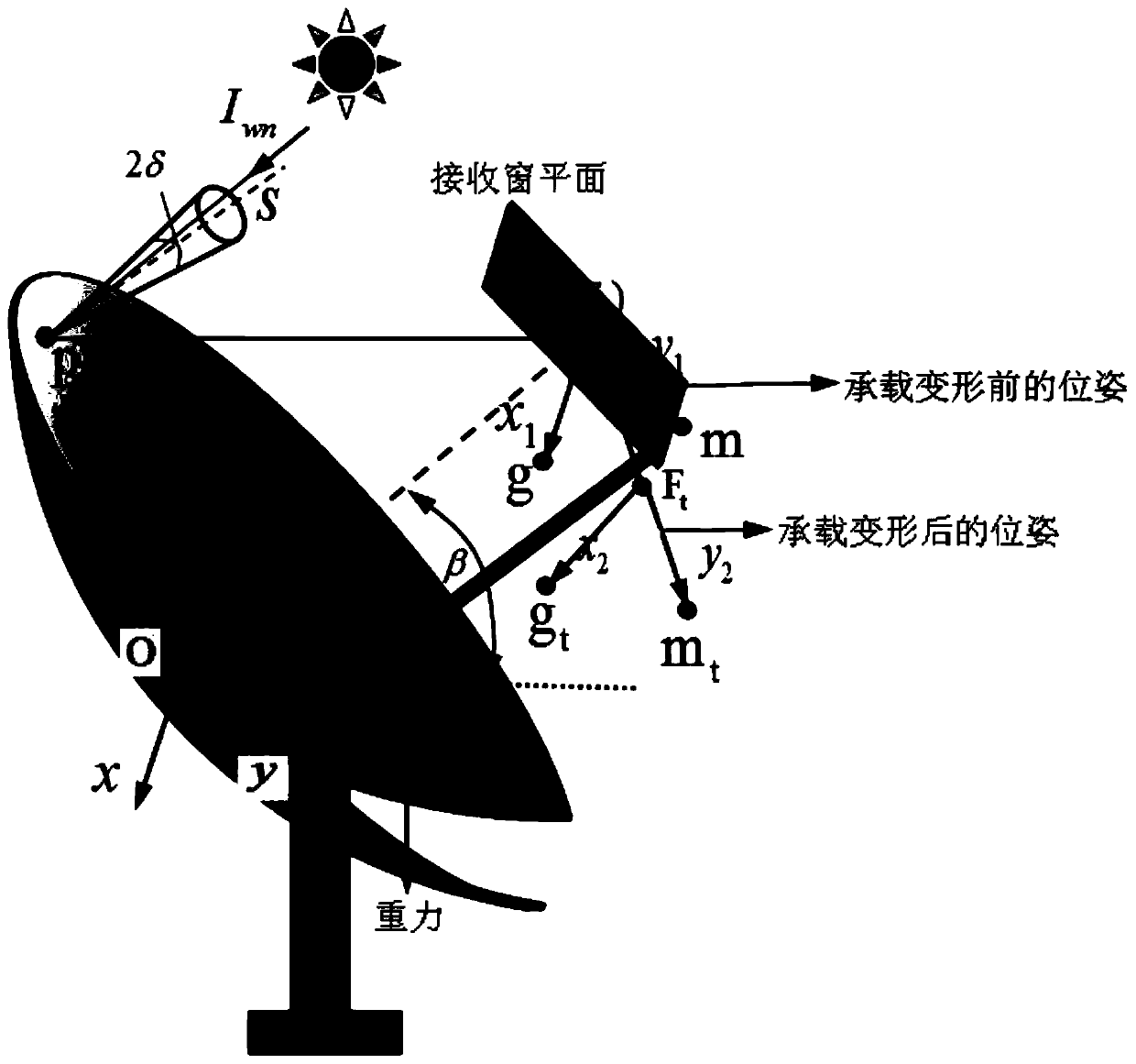

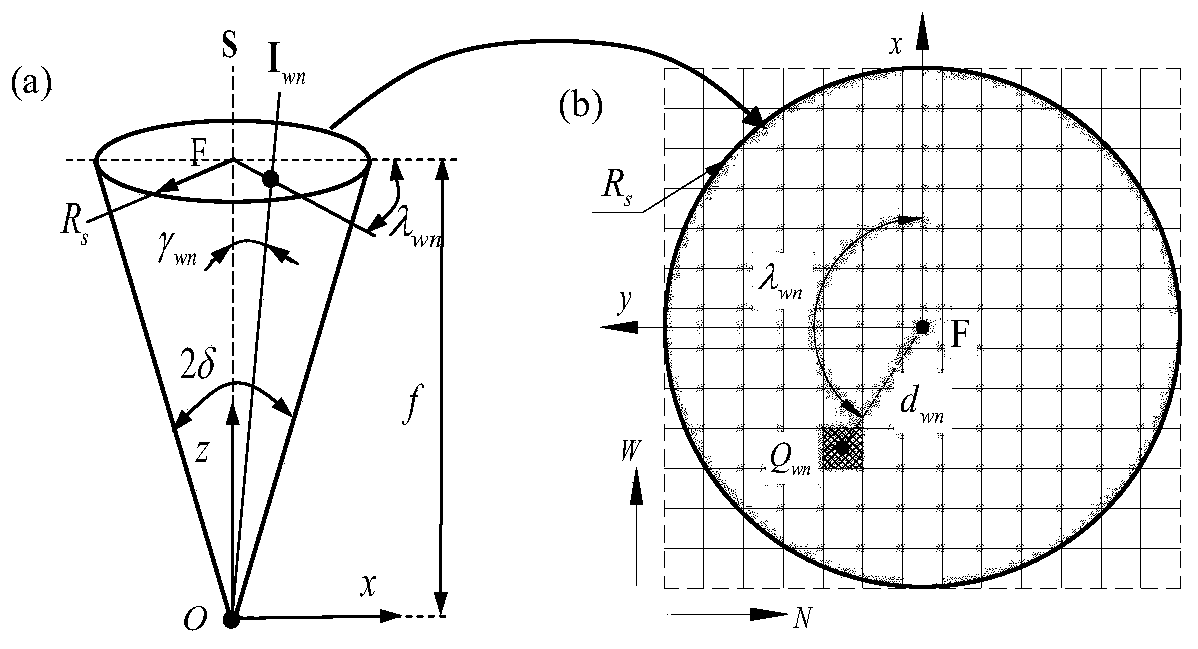

[0081] Step 1: Establish the structural finite element model of the dish concentrating system, divide the structural finite element model of the dish concentrating system into grids, and output the spatial coordinate information of each grid node of the concentrator reflector under the non-loading condition , to calculate the optical information of the dish concentrator under the condition of no optical error and no loading condition. Its specific operation is as follows:

[0082] Step 1.1: Establish a global coordinate system for mechanical and optical analysis. The global coordinate system O-xyz is established at the vertex O position of the parabolic mirror of the dish concentrator, the z-axis points to the focus F of the parabolic surface, and the focus F position vector F=[0,0,f], f is the parab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com