Low-field nuclear magnetic resonant technology method for designing water-based printing ink formula

A technology of low-field nuclear magnetic resonance and printing ink, which is applied in the fields of nuclear magnetic resonance analysis, material analysis through resonance, ink, etc., can solve problems such as large labor force, complicated experiments, and large consumption of chemical reagents, so as to speed up the research and development process, The operation process is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

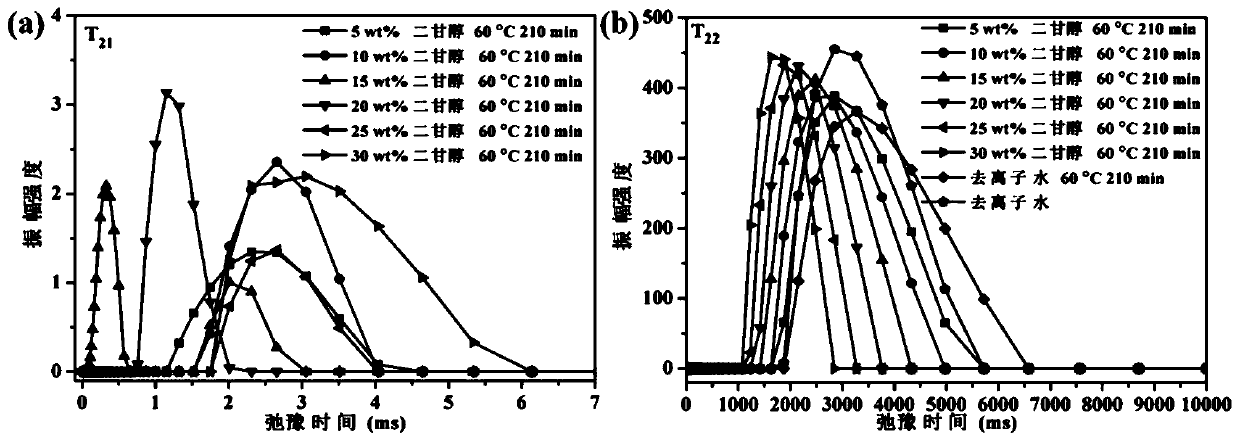

[0046] This embodiment provides a method for screening direct-injection dispersed printing ink humectants based on low-field nuclear magnetic resonance technology, and the specific implementation steps are as follows:

[0047] (1) prepare different mass fractions of isopropyl alcohol, ethylene glycol, diethylene glycol, glycerin and propylene glycol aqueous solutions, and the concentration of each humectant aqueous solution is respectively 5wt%, 10wt%, 15wt%, 20wt%, 25wt% and 30wt% . Accurately weigh 1.5g of humectant aqueous solution and place it in a constant temperature (60°C) drying oven for 210min.

[0048] (2) Using PQ001 low-field nuclear magnetic resonance to conduct low-field nuclear magnetic analysis on the different moisturizing agent aqueous solutions in step (1). Using the CPMG pulse sequence method to collect nuclear magnetic resonance echo signals and measure the transverse relaxation time T of the humectant aqueous solution 2 , the parameters are set as: 90-d...

Embodiment 2

[0053] This example provides a method for screening direct-injection disperse printing inks based on low-field nuclear magnetic resonance technology. Through dynamic monitoring of water state distribution and moisturizing performance in direct-injection disperse printing inks, direct-injection disperse inks with the best water retention performance are screened out. printing ink. The specific implementation steps are as follows:

[0054] (1) Configure five kinds of direct-jet disperse printing inks, which are named R1, R2, R3, R4, and R5 respectively. Accurately weigh 1.5g of the prepared direct-jet dispersion printing ink sample, weigh 4 parts of each sample, and then place 4 parts of each sample in a constant temperature (60°C) drying oven for 0, 70, 140 and 210min .

[0055] (2) Use PQ001 low-field nuclear magnetic resonance to conduct low-field nuclear magnetic analysis on the direct-jet dispersion printing inks with different formulations in step (1). Using the CPMG pu...

Embodiment 3

[0059] This embodiment provides a method for screening direct-injection dispersion printing ink based on low-field nuclear magnetic resonance technology. According to the detection results, the relationship between the content and state of water in the ink and the outline definition of the printing pattern is deduced. Further, it is possible to screen out inks that can obtain higher-definition printing patterns, and the specific implementation steps are as follows:

[0060] (1) Configure direct-jet disperse printing inks with different formulas, named R-1, R-2, R-3, R-4, R-5, Y-1, Y-2, Y-3, Y- 4. Y-5, B-1, B-2, B-3, B-4, B-5, K-1, K-2, K-3, K-4, K-5. Accurately weigh 1.5 g of prepared direct-jet dispersion printing inks of different formulations.

[0061] (2) Use PQ001 low-field nuclear magnetic resonance to conduct low-field nuclear magnetic analysis on the direct-injection dispersion printing inks with different formulations in step (1). Use the CPMG pulse sequence method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com