A dynamic monitoring method and device for inner diameter shrinkage of wound metal liner

A metal liner, dynamic monitoring technology, applied in the field of monitoring, can solve the problem of real-time monitoring of the shrinkage of the inner diameter of the metal liner, etc., and achieve the effects of simple equipment, easy equipment, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

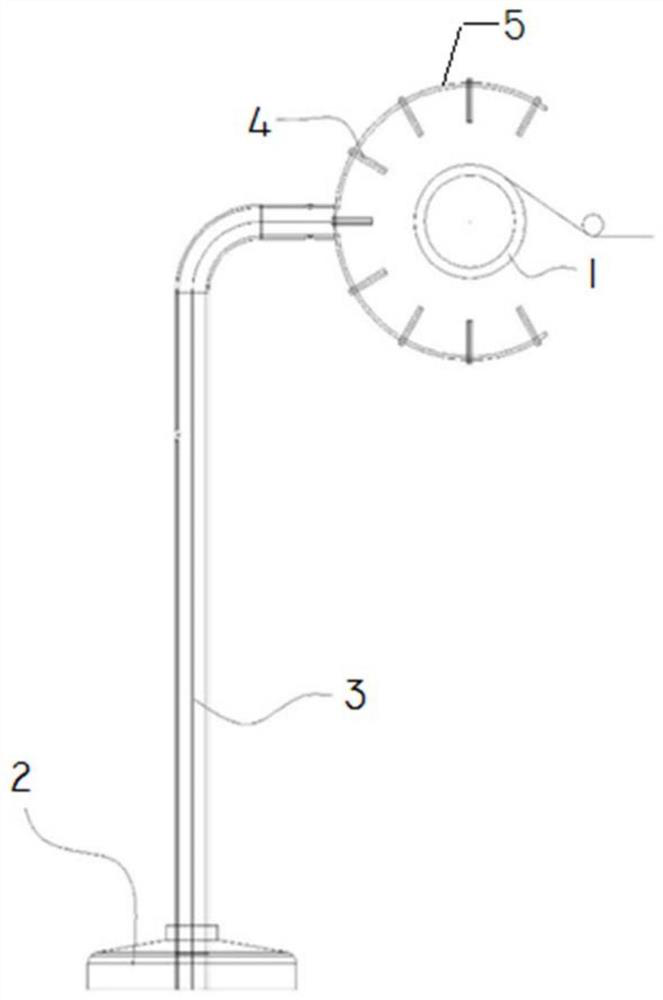

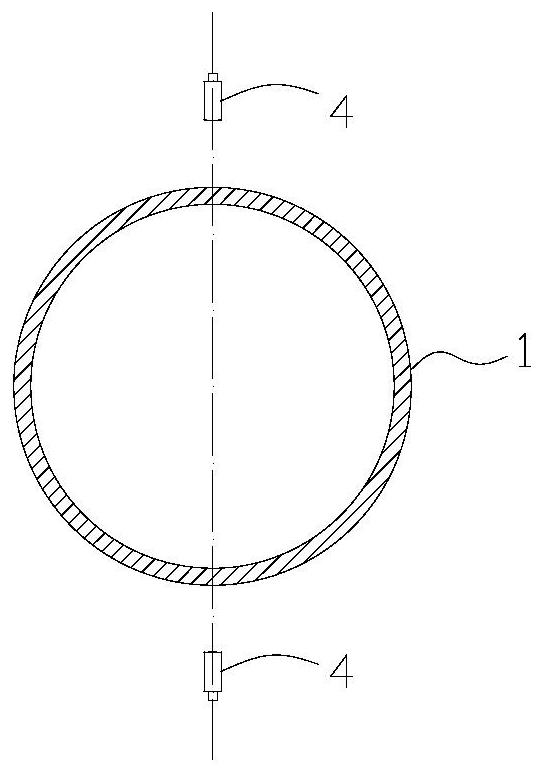

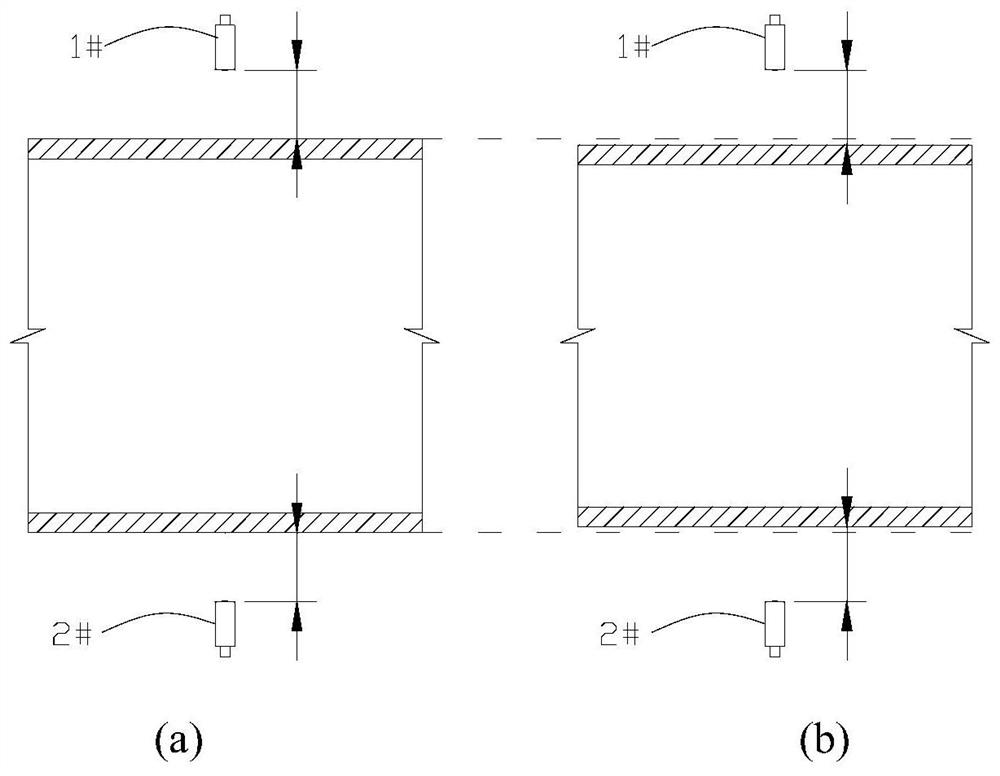

[0024] A dynamic monitoring device for the shrinkage of the inner diameter of the wound metal liner, its structure is as follows figure 1 As shown, the device includes a base 2 , a connecting bracket 3 , an eddy current displacement sensor 4 , and a fixing bracket 5 . The bottom end of the connecting bracket 3 used is connected on the base 2, and the top is provided with a fixed bracket 5 in a ring or arc-shaped structure. The fixed bracket 5 used in this embodiment is an arc-shaped structure, which is convenient to put in The metal liner 1 to be detected is conveniently specified. A double number of eddy current displacement sensors 4 are arranged in the fixed bracket 5 and are evenly distributed on the inner surface of the fixed bracket 5 . The metal liner 1 to be detected is arranged in the area surrounded by the fixed bracket 5 . In order to obtain better detection accuracy, the area surrounded by the metal liner 1 and the fixing bracket 5 is arranged concentrically.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com