Disc spring durability test system and method

A technology of durability test and disc spring, applied in the field of disc spring durability test system, can solve the problems of reducing detection efficiency and wasting time, and achieve the effect of improving controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to solve the problems of wasting time and reducing detection efficiency in the traditional disc spring durability test device, the present application discloses a disc spring durability test system and method through the following embodiments.

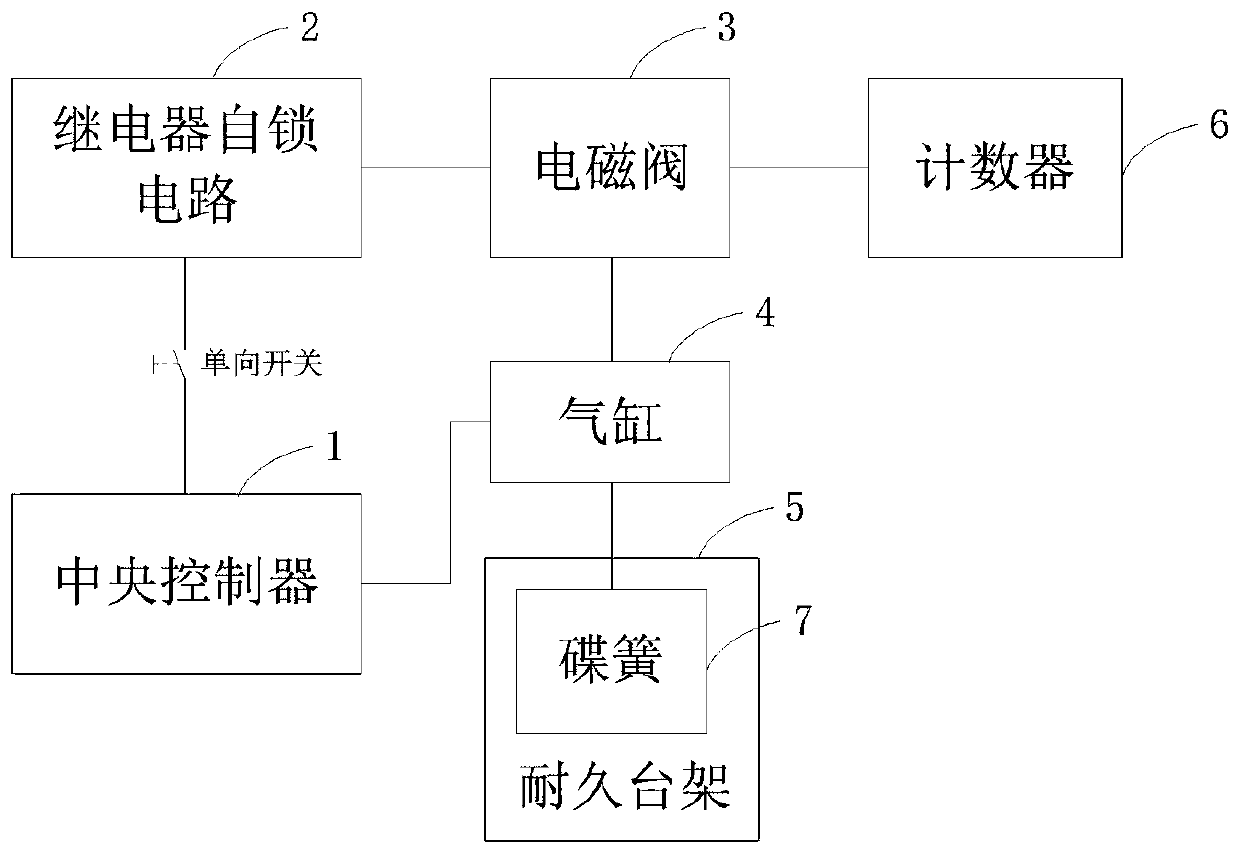

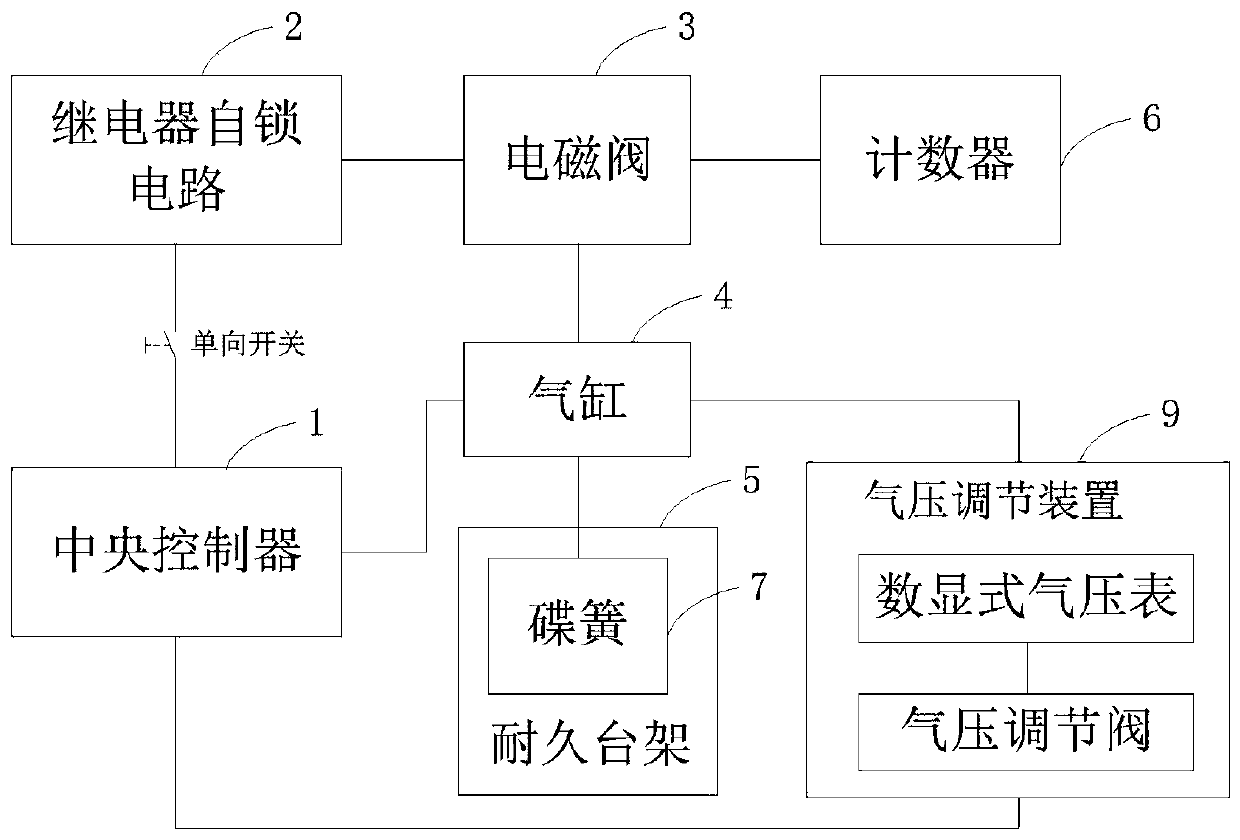

[0052] The first embodiment of the present application discloses a disc spring durability test system, see figure 1 As shown, the system includes: a central controller 1 , a relay self-locking circuit 2 , a solenoid valve 3 , a cylinder 4 , a durable stand 5 and a counter 6 .

[0053] The central controller 1 is connected to the relay self-locking circuit 2 through a one-way switch. The relay self-locking circuit 2, the solenoid valve 3 and the cylinder 4 are connected in sequence.

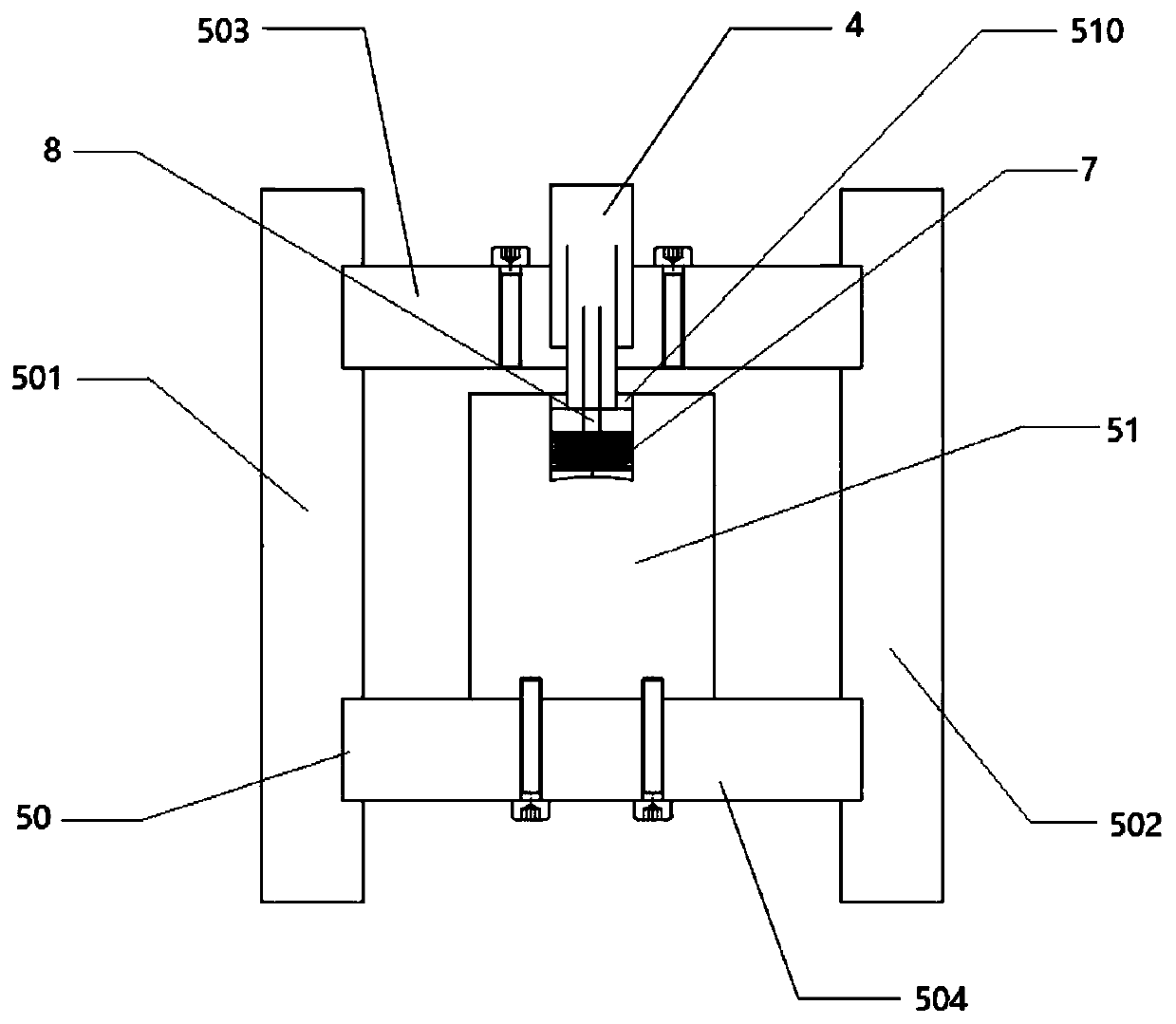

[0054] The durable stand 5 is used to place the disc spring 7 , and the piston 8 of the air cylinder 4 is correspondingly arranged above the disc spring 7 .

[0055] Before the test starts, the operator places a certain number of disc spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com