Three-dimensional dilatometer and working method thereof

A dilatometer, three-dimensional technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as inability to effectively monitor the three-dimensional expansion characteristics of soil samples, improve detection efficiency and accuracy, ensure measurement accuracy and effect, and improve accuracy. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

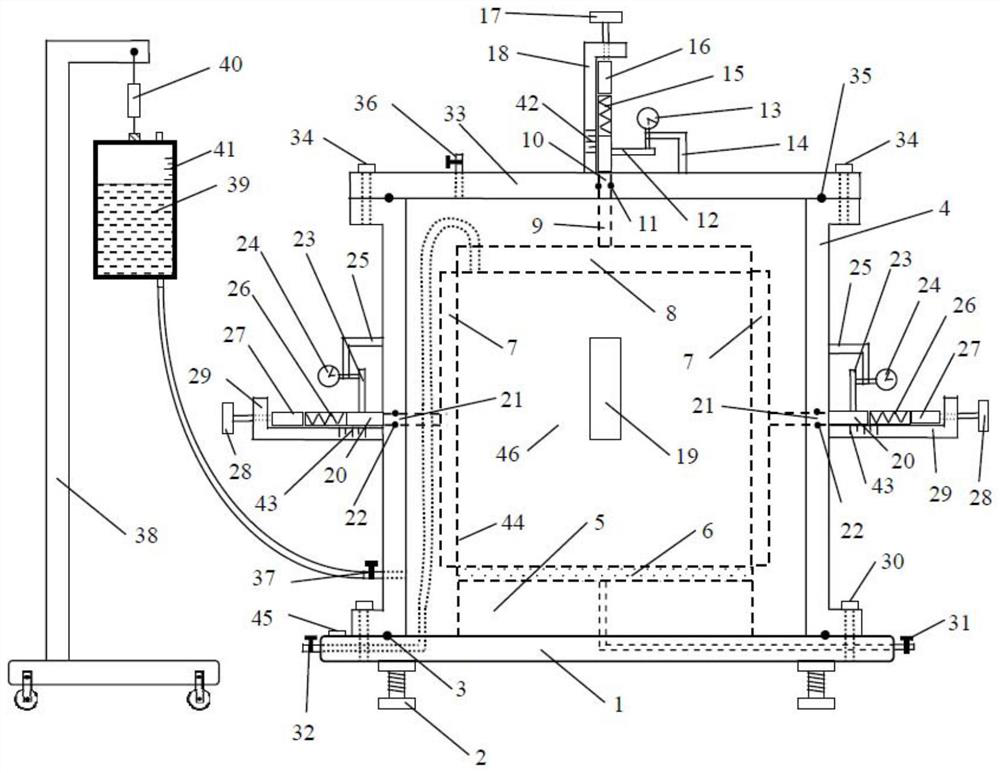

[0025] Such as figure 1 As shown, the present invention provides a three-dimensional dilatometer, which includes a base 1 on which a balancing water drop 45 is arranged, and a base adjusting bolt 2 is fixed on the lower part of the base 1 . The base 1 is provided with a pressure chamber side cylinder 4, and the pressure chamber side cylinder 4 has a square structure. The pressure chamber side cylinder 4 is fixed on the base 1 by base bolts 30 , and the bottom of the pressure chamber side cylinder 4 and the top of the base 1 are provided with a base sealing ring 3 . The pressure chamber side cylinder 4 is provided with a top cover 33 , the pressure chamber side cylinder 4 and the top cover 33 are fixed by the top cover bolts 34 , and the top cover sealing ring 35 is provided at the bottom of the top cover 33 and the top of the pressure chamber side cylinder 4 .

[0026] A top plate 8 and a bottom plate 5 are arranged in the upper and lower directions in the side cylinder 4 of ...

specific Embodiment 2

[0032] This embodiment is the same as the specific embodiment 1, the only difference is that no rubber film is provided on the side of the soil sample, and the top plate and the side plate are directly connected with the soil sample.

[0033] The working process of the present invention is: when in use, open the side cylinder valve or the top cover valve, open the bottom plate valve and the top plate valve. After preparation, record the initial readings of the top dial gauge, top load cell, side dial gauge, side load cell, top bracket scale, and side bracket scale, respectively. Saturate the soil sample with water from the bottom plate valve, measure the expansion deformation and expansion force of the roof and side plates at different water intake times, the top expansion deformation is calculated by the top dial gauge, and the top expansion deformation is verified by the top bracket scale; the top expansion The force is calculated by the top load sensor; the side expansion d...

specific Embodiment 3

[0035] This embodiment is the same as the specific embodiment 2, and the difference is only in the working process.

[0036] The working process of the present invention is: when in use, close the side cylinder valve and the top plate valve, open the bottom plate valve and the top cover valve. After preparation, record the initial readings of the top dial gauge, top load cell, side dial gauge, side load cell, top bracket scale, and side bracket scale, respectively. Saturate the soil sample with water from the bottom plate valve to ensure that the water level in the pressure chamber of the dilatometer is at least a certain depth higher than the top surface of the soil sample. Measure the expansion deformation and expansion force of the top plate and side plates at different water intake times. The expansion deformation of the top is determined by the top Calculated by the dial gauge, the top expansion deformation is verified through the top bracket scale; the top expansion forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com